ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

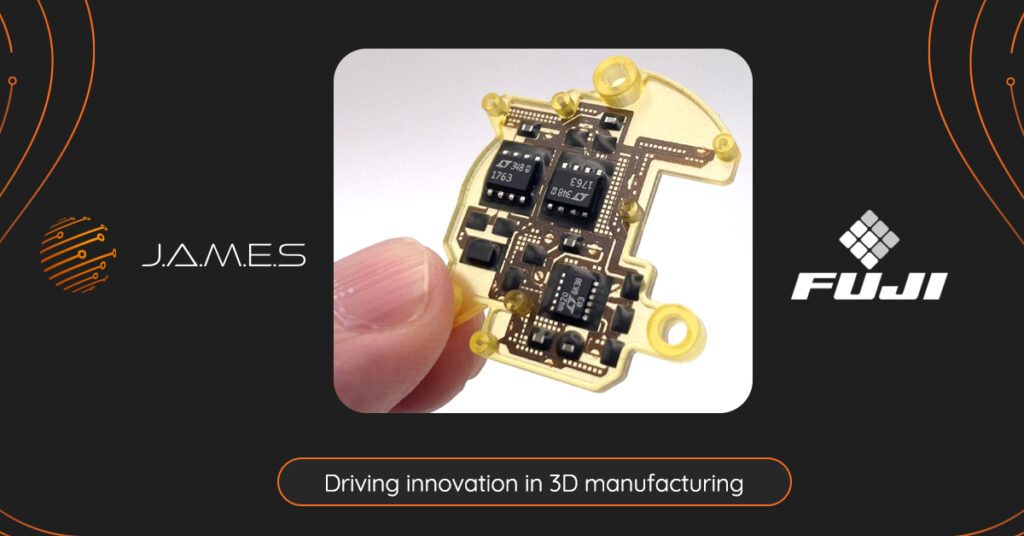

Fuji, J.A.M.E.S. Alliance Boosts Additive Electronics

Fuji Corporation has agreed to a partnership with J.A.M.E.S. GmbH to promote the growth of additive electronics.

Fuji has developed a unique electronics 3D printer—FPM-Trinity. Accordingly, it combines resin substrate printing, circuit printing, and component mounting to enable complete additive manufacturing of electronic devices in a single machine. In this area, Fuji has partnered with J.A.M.E.S., which is headquartered in Taufkirchen, Germany. Accordingly, the company has established an online community for the development of Additively Manufactured Electronics (AME).

New Solutions for the Electronics Industry

Specifically, the establishment of J.A.M.E.S. is to promote the development of AME and the company aims to explore the limits of AME and help turn it into a technology that anyone can use. The J.A.M.E.S. community is a place for manufacturers and users to communicate in real time, thereby enabling cross-company collaboration and sharing of knowledge.

Through this partnership agreement, Fuji aims to create opportunities to propose new ideas and solutions using FPM-Trinity. Moreover, to spread the use of AME in the electronics industry. The platform also provides an opportunity to make use of the J.A.M.E.S. network to exchange information with users, which can be used to improve the value of Fuji’s products and inform its business strategy.

Fuji and J.A.M.E.S. will provide forward-thinking solutions and ideas to the electronics community via this collaboration.

FPM-Trinity Features

1. Electronics 3D printer combining resin printing, circuit printing, and parts placement in a single machine

2. Digital printing process directly from CAD data, so there is no need for additional processes such as mask creation

3. Go from data input to completion in one day

4. Enables the creation of devices with 3D form factor

5. Sustainable manufacturing process that minimizes waste materials

FPM-Trinity Future Developments

Fuji currently offers a sample manufacturing service using the FPM-Trinity. Moreover, the company is also working towards releasing the machine itself for sale. Fuji will further the development and diffusion of its additive manufacturing technology. Thereby, providing solutions to industry issues such as the acceleration of the internet of things, the realization of a sustainable society, and the shortening of product development cycles.

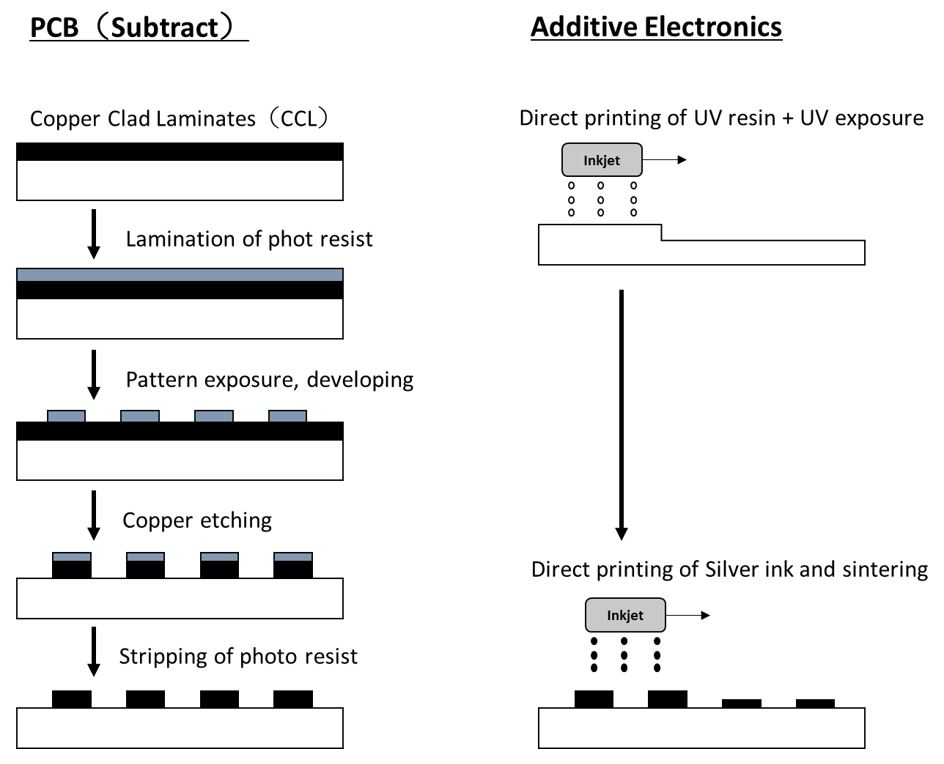

Conventionally, the manufacture of printed circuit boards (PCBs) is through a subtractive process in which unnecessary copper and resin are etched away through wet processes. In contrast, with additive manufacturing, 3D printers are used to selectively apply material only to required locations. Hence, minimizing material use and liquid waste.

When this method is applied to electronics, it is known as Additively Manufactured Electronics (AME) is the process of applying this method to electronics. This has been gathering momentum of late.

About This Article:

Image Credit: All images used courtesy of Business Wire