ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

DNP Touts Encoder Disks to Support Factory Automation

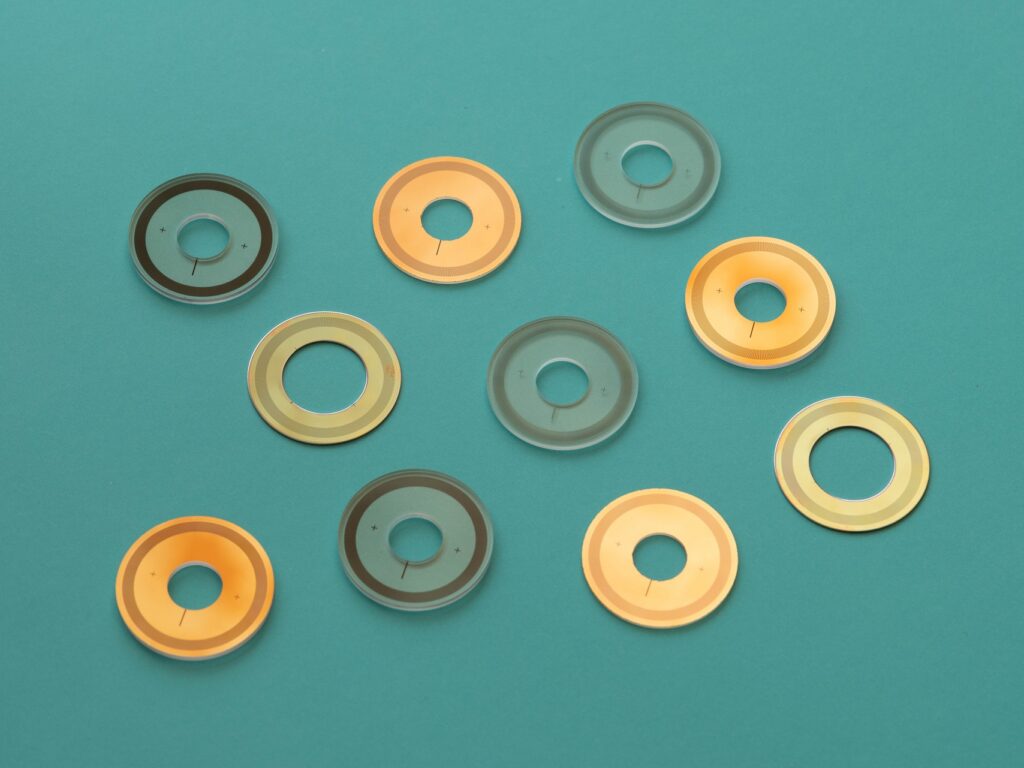

Dai Nippon Printing Co., Ltd. (DNP) will enter into the development and manufacturing of Encoder Disks (ED) employed in electronic components. These products detect the position, movement direction, and rotation angle of industrial robots.

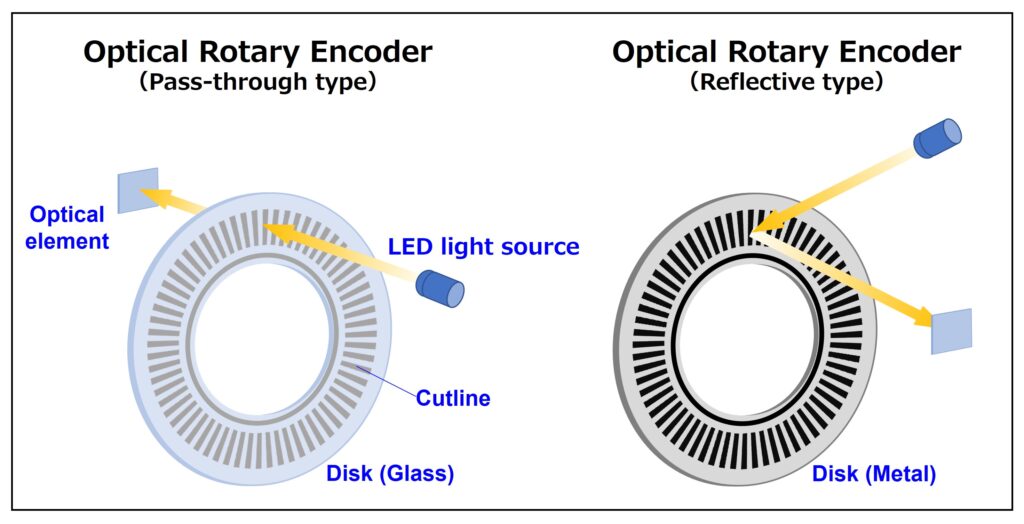

Specifically, an ED is a disk with engraved fine scales. Various sensors mounted inside the encoder detect reflected light on, or transmitted through, the disk. Also, by converting this into electrical signals, they detect and control whether industrial robots are moving and rotating in the correct manner.

Amid the progress of factory automation in recent years, demand for encoders is increasing. Specifically, demand for encoders capable of detecting the movement and rotation of robot motors is getting high. In response to this situation, DNP has decided to enter the development and manufacturing of ED.

The company will combine its proprietary strengths in precision thin film coating and patterning technology cultivated in connection with the development of a variety of display products.

Product Features

The provision of ED compatible with various materials and models

DNP will provide ED manufactured from various materials. Among them include glass, resin, and stainless steel substrates. This aims to meet the diverse needs of client companies. DNP’s ED is compatible with two types of encoders – Rotary Encoders and Linear Encoders.

High performance and reliability

Using DNP’s proprietary cutting methodology, it offers Glass ED that is more resistant to breakage, and Metal ED that is free of partial distortion. In addition, it applied a thin layer of transparent protective film and highly reflective material. As a result, it is possible to boost ED with approximately 50% more reflective strength compared to uncoated ED products produced in-house. With these products, it will increase the resistance to shocks when installing ED. At the same time, it will also reduce the power consumption of light sources that irradiate the ED.

Mass Production Possible

DNP manufacturing is carried out on large-scale machinery with multiple faces attached. Accordingly, it is possible to mass-produce ED to match the needs of client companies. Also, manufacturing large-scale disks is also possible. DNP’s proprietary cutting methodology and automatic product inspection equipment enable it to provide high-quality disks.

Going Forward

DNP will provide ED to companies that manufacture servomotors used in industrial robots and machine tools. It aims for total sales of 1.5 billion yen by FY 2025. Also, it will develop ED for autonomous sensors, a market that is expected to expand in the future.