ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Samsung Electro-Mechanics Eyes Automotive Power Inductor

Samsung Electro-Mechanics Co., Ltd. sets its sights on the automotive power inductor market with the mass production of power inductors. Specifically, these devices are essential components of electric and autonomous vehicles.

Power inductors are core electronic components applied to power circuits. They convert electricity from batteries into the power required by semiconductors and supply stable current. To his end, power inductors are called the ‘second MLCC’.

Generally, a car requires more than 100 power inductors, more than twice as many as a smartphone. The industry expects the number of power inductor installations to more than double by 2030. This results from the expansion of usage area to electric vehicles (EVs) and autonomous driving.

Features of Power Inductors

Samsung Electro-Mechanics previously announced that it is mass-producing power inductors for EV cameras with autonomous driving systems. A power inductor provides stable power to semiconductors that process autonomous driving information by preventing sudden current changes. This time, the mass production of automotive power inductors is the first for Samsung Electro-Mechanics.

Generally, the performance of a power inductor is determined by the raw materials, magnetic substances (objects with magnetic properties), and the number of coils (copper wires) that can be wound inside. Thus, to increase the performance of the power inductor, it is necessary to improve the properties of magnetic substances and wind more coils in the limited space.

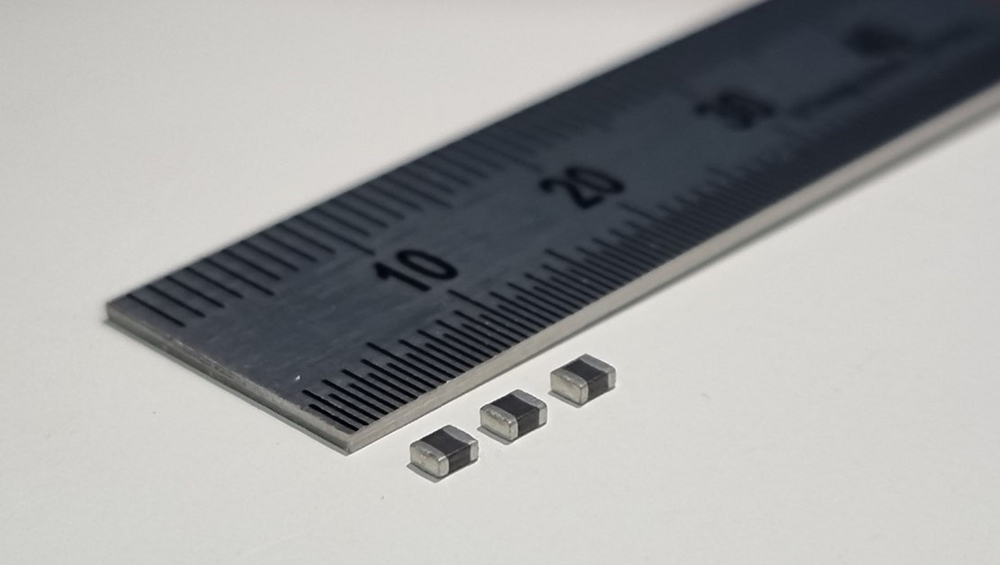

Samsung Electro-Mechanics developed two types of 2016 size (2.0mm wide and 1.6mm long) power inductors with capacities of 1.0µH and 2.2µH, respectively.

The company’s power inductors are thin-film products where thin coils are formed on the package substrates. They feature higher productivity and miniaturization than the wire wound type where the coils are wound on magnetic substances.

Mainly, Samsung Electro-Mechanics develops magnetic substances with excellent properties and low losses on its own. It leverages its own materials technology accumulated through MLCC development. Moreover, the company applies the photosensitization method used in semiconductor package substrates to precisely form coils with minute spacing. Photosensitization is a method of engraving circuits using light.

In addition, its power inductor also meets AEC-Q200, an automotive electronic component reliability test standard that requires a high level of reliability. This certification allows the use of the power inductor in other applications such as in-vehicle ADAS and infotainment.

Expansion of Demand

The expected growth of the power inductor market centers on high-performance products. This results from increasing demands arising from the high-performance and multi-functionalization of electronic devices and expansion of the automotive industry such as autonomous driving and electric vehicles.

By 2028, the power inductor market size will reach approximately US$3.65 billion, at a CAGR of approximately 9%. In particular, the market will require power inductors that can withstand high currents as the amount of used current continues to increase. This is due to the growing number of semiconductors installed inside vehicles. Also, the improving performance resulting from the sophistication of automotive functions is a factor. Meanwhile, the market for automotive power inductors will show high growth at a CAGR of about 12%.

Chang Duckhyun, CEO of Samsung Electro-Mechanics, said, “Power inductors are expected to experience high growth as the market for autonomous driving and electric vehicles expands. Samsung Electro-Mechanics plans to develop power inductors into the ‘second MLCC’ based on our differentiated technology through the convergence of materials and package substrate technologies.”