ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Siemens Unique Portfolio Boosts Production Efficiency

Siemens will be presenting at this year’s EMO how companies in the machine tool industry can meet energy efficiency and sustainability requirements. Notwithstanding, meeting the demand for high-quality, affordable, and individualized products.

Siemens will take part in the event with the motto “Accelerate transformation for a sustainable tomorrow”.

Based on automation, the key to meeting these challenges lies in digitalization and the associated data transparency. Perhaps, only a digital enterprise can combine the real and digital worlds. On top of this, make the right decisions using smart software tools to produce flexibly, quickly, and sustainably.

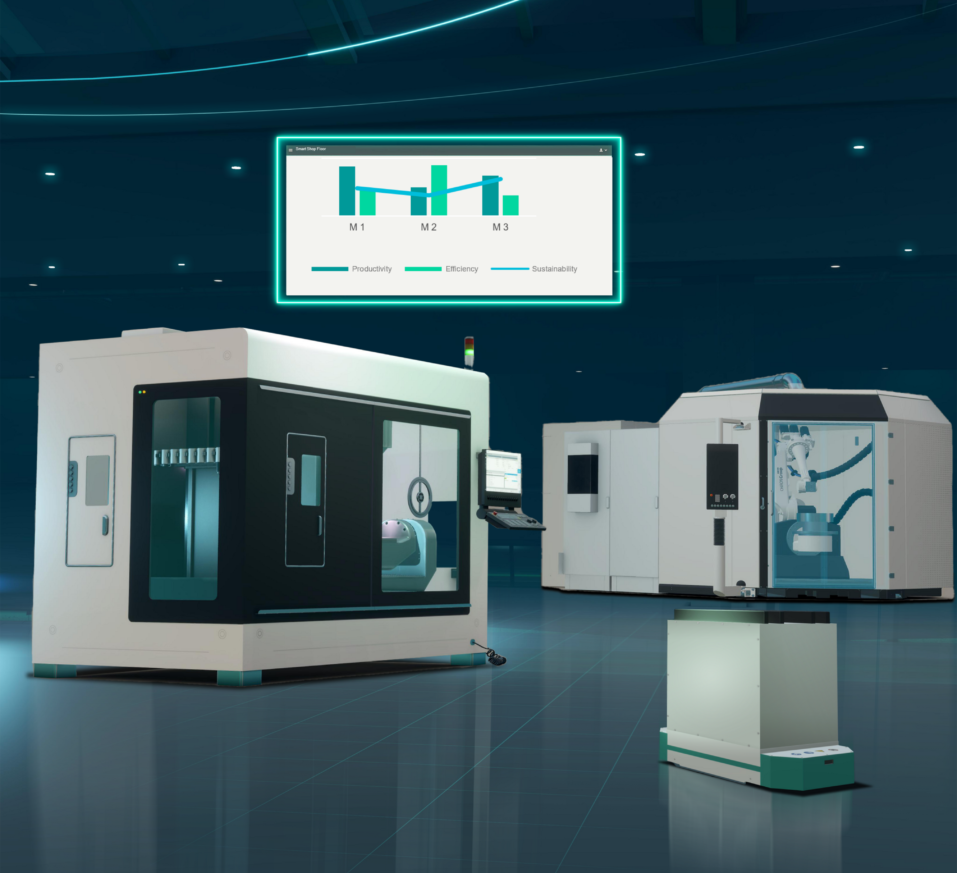

CNC digitalization portfolio for the machine tool industry

For this purpose, Siemens is presenting Machinum at EMO. Machinum comprises the entire CNC digitalization portfolio for increasing productivity and sustainability in parts manufacturing. In addition, because of Machinum, machine tools, and manufacturing areas can be analyzed and optimized, both virtually and in real life.

Furthermore, Machinum combines modern IT (information technology) with modern OT (operations technology). Thus, based on Siemens’ industrial expertise, Machinum creates productivity gains in many industrial use cases.

Most importantly, Machinum is an integral part of Siemens Xcelerator, the open digital business platform that includes a portfolio of software and IoT-enabled hardware, an ecosystem of partners, and a marketplace. With Machinum, companies in the machine tool industry can make digital transformation easier, faster, and scalable in both manufacturing and design. Combined with Sinumerik One, the Digital Native CNC control, which is also part of the Siemens Xcelerator portfolio, a transformation towards the Digital Enterprise succeeds – for future-proof and sustainable manufacturing with machine tools.