ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

NSK Tests Condition Monitoring for Linear Guide Tools

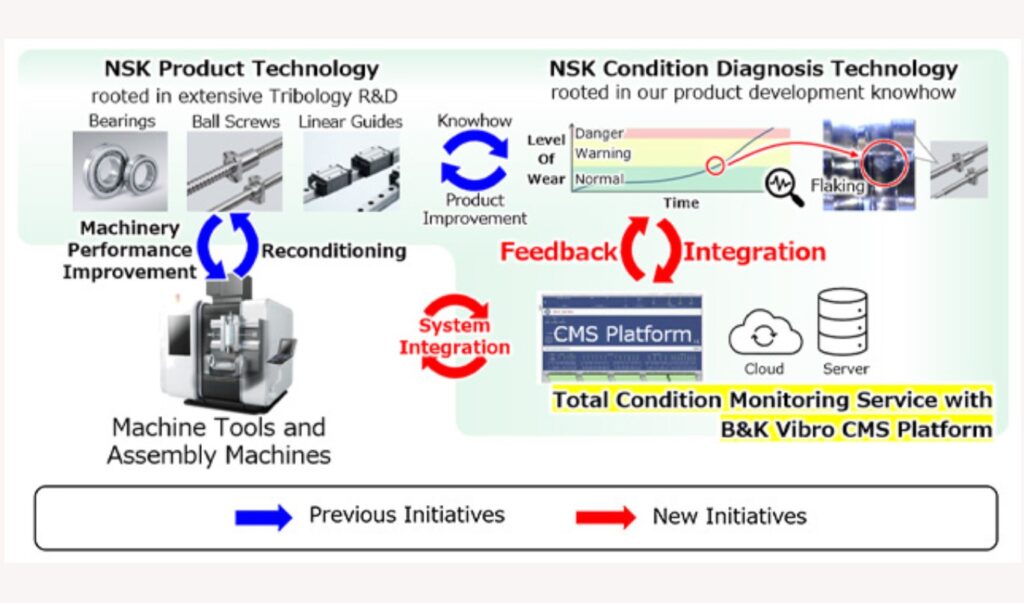

NSK Ltd. will bring to market a new type of condition monitoring system capable of analyzing and diagnosing the condition of linear motion products.

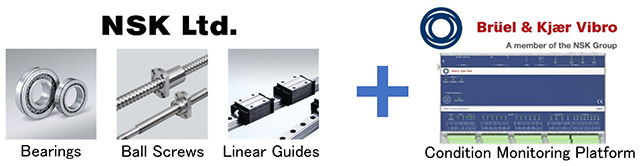

Particularly, NSK has been expanding its condition monitoring system business for rotating machinery since 2021 with the acquisition of Brüel & Kjær Vibro (B&K Vibro).

NSK will exhibit the system at EMO Hannover 2023, the world’s largest machine tool exhibition in Hannover, Germany from September 18-23, 2023.

Background

Conventionally, condition monitoring has been focused on rotating machinery. However, NSK’s new system will also diagnose linear motion machinery to evaluate whether there are any abnormalities in machinery or components. Thus, condition monitoring helps secure stable operations free of costly unplanned downtime and more efficient maintenance scheduling.

NSK will conduct pilot tests with the aim of launching the solution in fiscal 2024.

Recently, there has been a growing need for predictive maintenance systems to monitor the condition of machinery and equipment. These systems help detect abnormalities early and prevent problems before they occur.

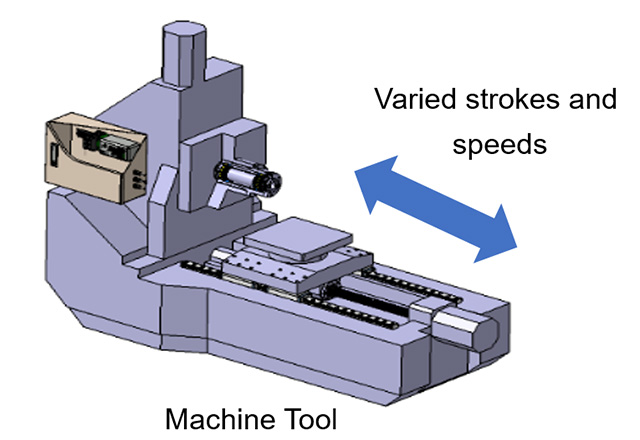

Condition monitoring has been utilized in machinery and equipment that operates at a relatively constant rotational speed. Specifically, relating to wind power generators and large turbines in petrochemical plants. Today, there is a growing demand for systems that can monitor complex manufacturing and machining processes, including linear motion components.

Features

I. NSK Proprietary Diagnostic Technology Tailor Made for Linear Motion

NSK has cultivated advanced diagnostic technology in our development of linear motion products. Particularly, the company utilizes tribology technology in developing ball screws and linear guides as well as bearings. This diagnostic technology will be integrated into B&K Vibro’s condition-monitoring products and to achieve predictive maintenance at production sites.

II. Connected Condition Monitoring

Linear motion mechanisms are subject to changes in position, speed, and operation patterns, which makes it very challenging to implement highly accurate condition monitoring. In addition, it is necessary to understand the operating conditions of the equipment and perform condition monitoring under appropriate conditions. This is essential to perform condition monitoring of complex machining processes that combine rotating and linear motion mechanisms.

The system being developed will provide highly accurate diagnosis even during complex machining processes. Particularly, by linking with machinery and equipment to obtain operating information in real time.

Benefits

Manufacturers can expect to benefit by implementing NSK’s condition monitoring solution in production facilities. Particularly, in the monitor machinery and equipment performing complex work including a combination of rotating and linear motion components.

It can also evaluate the presence or absence of abnormalities in machinery and equipment without specialist knowledge. In addition, it will help improve the stability and reliability of plant operations through predictive maintenance strategies made possible with the system.

Furthermore, to contribute to customers’ predictive maintenance through condition monitoring, NSK will also utilize condition monitoring data to further improve its portfolio.