ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

NSK's New Lineup Meets Manufacturers' Needs

The demands placed on machine tools are ever-changing. For that reason, NSK Ltd. has beefed up its portfolio to meet the changing needs of production floors.

Moreover, the company will highlight at the forthcoming EMO Hannover 2023 in Germany its latest products and technologies. NSK has been striving to contribute to the growth and achievement of various machinery industries.

NSK will exhibit at EMO Hannover 2023, one of the world’s largest machine tool exhibitions. Particularly, the annual event will take place at the Hannover International Fairgrounds in Germany from September 18-23.

NSK’s booth will feature dynamic exhibits that allow visitors to experience first-hand the actual motion and features of the products. Most importantly, NSK will introduce them for the first time.

Main Exhibits

1. ROBUSTDYNA™ Ultra-High-Speed High-Load Capacity Angular Contact Ball Bearings

The product carries an innovative design that excels at both heavy-duty cutting and high-speed rotation. Thus, having rough and finish on a single machine. Furthermore, it enables shorter cycle times because its high impact resistance contributes to long-term stable spindle operation.

2. Ball Screws for Next-Generation High-Accuracy Machine Tools

Particularly, the new ball screws can reduce “quadrant glitch” motion errors and improve machine tool productivity. They can also eliminate or reduce the time needed for burnishing/polishing. Hence, they contribute to saving energy consumption.

3. Long Life Series DH/DS NSK Linear Guides™

NSK’s special TF “Tough” heat treatment doubles service life and achieves a world-top-class dynamic load rating. Furthermore, the new guides provide machine reliability and expand design possibilities for more compact or longer-lasting machines

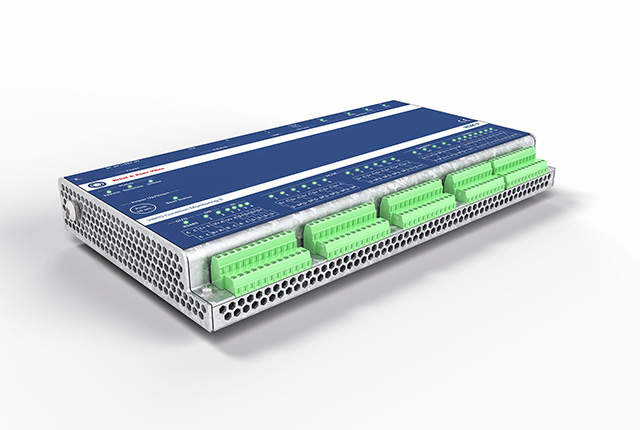

4. VCM-3 Condition Monitoring Unit New Window

The new unit offers cutting-edge automatic machine fault detection and diagnosis. Hence, it can offer immediate insights without previous diagnostic expertise. It has no complicated set up as it connects to the company’s cloud platform or to a customer’s server.

5. Linear Guide/Ball Screw Condition Monitoring in VCM-3

Connects with machine tool controller to automatically collect vibration data at the appropriate time.

NSK’s advanced diagnostic technology enables highly accurate diagnosis of bearings, ball screws, and linear guides. In addition, the company will also offer live demonstrations of the detection of ball screw wear.

6. Active Caster Omnidirectional Drive Unit

The unit offers compact all-in-one wheel, steering. Furthermore, the drive unit is suitable near people. Thus, they are ideal for service robots, collaborative robots, among others.