ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

TRUMPF’s New Business Model Tackles Labor Shortage

Last year, TRUMPF began offering sheet-metal fabricators the opportunity to use its fully automated TruLaser Center 7030 laser machine under a Pay per Part business model. Moreover, TRUMPF provides customers with a high-performance machine and a material storage system through an equipment-as-a-service (EAAS) contract.

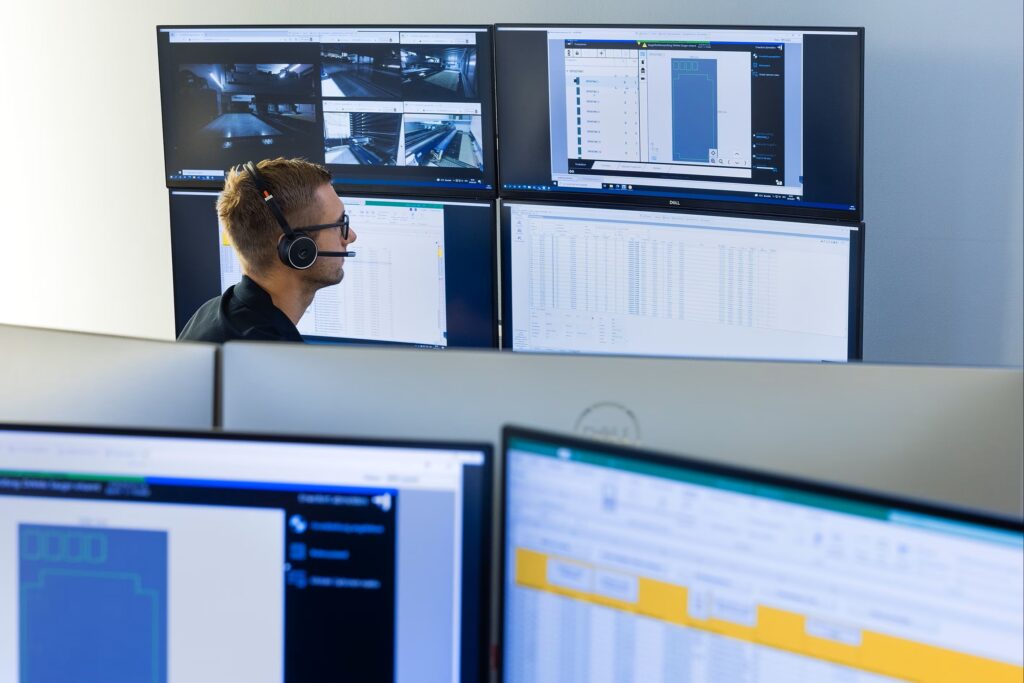

Customers can then use the TruLaser Center 7030 for their own manufacturing requirements. The fully automated laser machine has cameras, sensors, and remote-control systems. This enables TRUMPF to operate the machine from its Remote Control Center in Neukirch without the user having to be present all the time.

“Pay per Part is yet another example of TRUMPF’s market-leading position in the realm of digital connectivity. We can operate the TruLaser Center 7030 remotely and use the machine data to improve the efficiency of the manufacturing process. Thus, this gives our users a competitive edge,” says Thomas Schneider, CTO at TRUMPF Machine Tools.

Accordingly, the Pay per Part model enables TRUMPF to remotely schedule and control the operation of the manufacturing cell while also providing machine programming and maintenance services. In case of machine failure, TRUMPF will get a notification without delay. Thus, can move to remedy the problem as quickly as possible. Under this new business model, customers are only charged for parts that are actually manufactured.

Helps Tackle Labor Shortage

Reiff Umformtechnik is one of the first companies to adopt TRUMPF’s new business model. Based in Leipheim, Germany, this metal-processing company supplies various industries. Particularly, including the mechanical engineering and vehicle manufacturing sectors. Accordingly, the shortage of skilled workers has presented it with some significant challenges.

“We have huge numbers of orders coming in, but too few staff to keep our machines working at capacity. Pay per Part helps us increase machine availability and improve our production processes,” says Reiff. In addition, he also points to further benefits, such as the ability to deploy innovative technologies without the need for a personnel.

All-Inclusive Package

Pay per Part allows companies to keep their machines operating without having to hire new labor. It also enables automated and cost-effective production of small. Should a malfunction occur that is difficult to remedy remotely, TRUMPF notifies the user and instructs them what to do.

In addition, the team from TRUMPF can set up the machine to the customer’s exact requirements and leverage data analytics to obtain maximum productivity.

Greater Customer Focus

TRUMPF, too, benefits from Pay per Part. Particularly, this new business model supplies an in-depth understanding of customer requirements. Thus, enabling the high-tech company to undertake targeted improvements to its own machines and software.

This, in turn, facilitates the development of new technology. Combined with the TruLaser Center 7030, the Pay per Part business model offers an attractive option for any company that has full order books and a shortage of skilled labor.

Presently, TRUMPF offers the model in Germany, Austria, the Netherlands and Switzerland.

Pay per Part has cemented TRUMPF’s reputation as a pioneer of innovative business models in the global sheet-metal community.