ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Dobot Robotics Opens First German Base

Recently, Dobot Robotics opened Dobot Europe GmbH, its European subsidiary and first German office, located near Frankfurt am Main. With this in place, it will focus on even closer cooperation with its local customers, like automotive manufacturers and partners. Moreover, this complements its global network of 200 sales partners and additional locations in China, the United States, and Japan.

Having already sold 68,000 robots worldwide, Dobot is now launching the new CRA Series of collaborative robots (cobots) and the associated VX500 smart camera to the German market. The cross-sector products expand the range of high-performance, easy-to-use cobot solutions. Primarily, these are for companies in the automotive, electronics and metal processing industries, and logistics sector.

“We are seeing a rapid expansion of application scenarios for cobots especially in the manufacturing industry. With the CRA Series and its high-performance all-in-one joint, we can provide a cobot solution with improved efficiency and highly consistent quality even for the most demanding users,” explains Jerry Liu, CEO of Dobot.

The new products take human-machine collaboration to a new level in terms of reliability, safety and expandability. “In doing so, we aim to meet the individual needs of our partners and customers across different sectors and company sizes to accelerate the transition to automated production. Therefore, our first German location and the employment of dedicated experts who are very familiar with the local market are the next logical step for us,” said Liu.

In the future, a total of seven employees from the areas of channel management, technical customer support, sales engineering and user training will be based in Neu-Isenburg near Frankfurt. Also, a showroom and a training lab will be available to both partners and customers on-site.

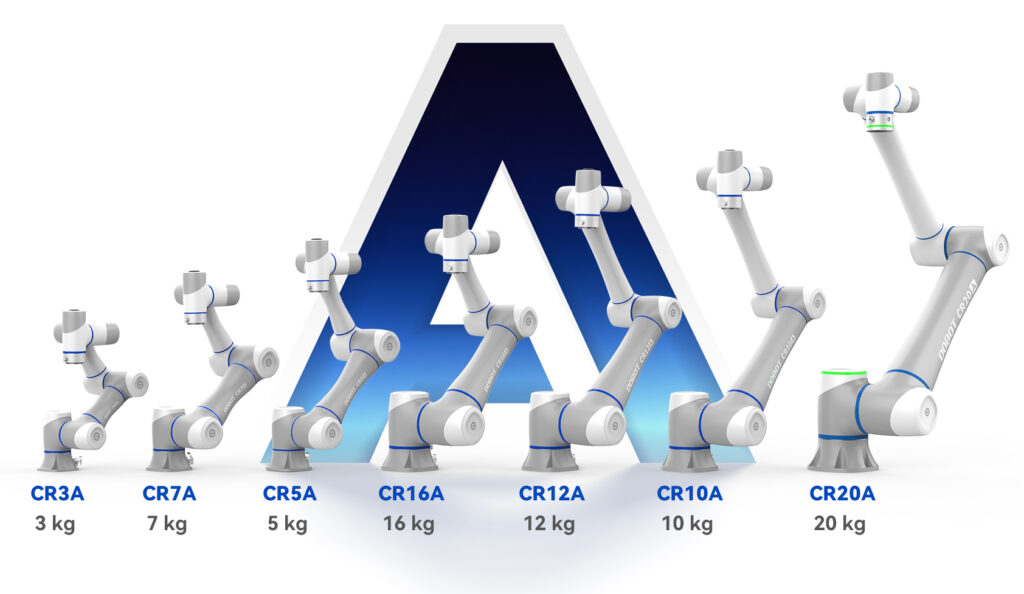

CRA Series: Even higher performance and precision combined with advanced safety features

The CRA Series comprises a total of seven models with payloads from 3 (minimum) to 20kg (maximum). Also, the series has a working radius range of 620 to 1,700mm. They are used in high-precision industrial applications, such as pick-and-place, sorting, screwing, inspection, gluing, welding, transporting, polishing and palletizing.

Compared to the previous model, the CRA cobots offer a more powerful gearbox that shortens a work cycle by an average of 25 percent. The control boxes of the devices are also about 25 percent smaller. They offer optional IP54-rated protection in demanding environments, reducing long-term maintenance requirements. Micrometer-level anti-vibration technology ensures that the robot stops quickly and steadily, even at high speeds. In combination with the TrueMotion function, the CRA cobots ensure trajectory accuracy even during complex curved operations. Thus, it adds a new level of stability to all use cases.

Electromagnetic brakes stop the gripper arms from descending within 18 milliseconds, protecting workers in the immediate vicinity even during power outages. In addition, the models with payloads of 3, 5 and 10kg are compatible with Dobot’s self-developed SafeSkin technology. This detects obstacles within a radius of 15cm and avoids collisions.

Moreover, the CRA Series supports Modbus, Ethernet/IP and Profinet communication, and connects seamlessly with PLC and other automation systems. Also, it features 24 available I/O ports and PNP/NPN switching that easily carries out expansions. The cobots has a new operating software that supports graphical programming, scripting and drag-to-teach for trajectory replay. It is particularly user-friendly and compatible with diverse end devices, from PCs to tablets.

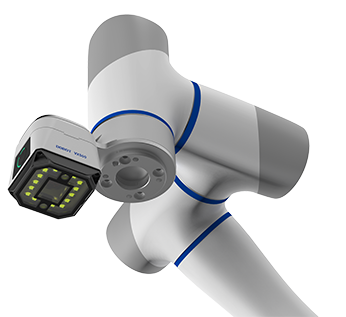

Additionally, the company introduced the new VX500 Smart Camera. Specifically, this smart camera uses Dobot’s proprietary 2.5D spatial compensation technology, which enables robots equipped with it to detect tilted or angled objects more accurately. This enables a variety of vision-based automation scenarios for cobots of the new CRA Series as well as the existing CR Series. Users can set up the new camera quickly and easily via Dobot’s latest software.