ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Korean Robot Start-Ups Make Big Strides on Manufacturing and Logistics Scenes

The COVID-19 pandemic proves a blessing in disguise for Korean smart factory system makers as well as robotic makers.

Putting production at factories in geopolitically unstable countries at risk, the pandemic has been threatening to disrupt global supply chain for everything from cars to smart phones to consumer electronics.

To tackle the unprecedented challenges, manufacturers across the world started to reorganize their supply chain system, reshoring their offshore factories back home or deploying smart factory system and robots at their assembly lines to save costs and improve productivity.

Korea is no exception. Korean manufacturers are now turning to smart factory system and robots for productivity, cost-saving and workplace safety, as the country is rapidly digitalizing its economies to adopt Industry 4.0 across all manufacturing sectors.

Especially, robots are widely being deployed across workplaces to replace human labor force in repetitive, labor-intensive, and dangerous job environment like assembly lines, logistics and delivery system, and warehouses to create untact and unmanned working environments

That is now laying the breeding ground for Korean robot makers.

Cases in point are Rainbow Robotics and Neuromeka.

Breeding Ground

Founded in Feb. 2011, Rainbow Robotics have grown rapidly over the past two years through 2021, capitalizing on strong demand for its collaborative robot RB and RB-N series – a next generation for 6-axis robot arm system.

A pioneer of two-legged, or biped human-like robot ‘Hubo”, the maker has so many successful use cases where its collaborative robots are not only working together with assembly line workers to do welding and molding, but also serving as a robot barista at unmanned kiosks to make cups of coffees.

For example, the RB series are now deployed at machinery parts and components maker STS Precision’s factory floors to replace factory floor workers in the so repetitive and dangerous job to feed raw materials and then take back finished tools and parts out of CNC, or computer numerical controller machines. According to STS Precision that supplies various tools and machinery parts for semiconductor chip makers, the company is benefitting from a gain of 40% to 50% in the productivity with the deployment of the collaborative robot series.

The RB series can also collaborate with novice welders across factory floors to help them to weld various parts and components as efficiently as seasoned welders, while being deployed at the injection molding processes to load and unload them out of injection molding dies to replace human work force in the such dangerous work environment.

Use cases don’t stop there. The RB robot series are working as Boba Robo, U.S-based beverage kiosk system operator’s unmanned coffee-making barista robot to make various beverages and coffee, using AI system. The operator started its first RB robot series-based beverage-making unmanned robot barista service at the Student Union of the University of Nevada, Las Vegas in February of 2021.

Coffee Maker

Rainbow Robotics is even gearing up to launch an unmanned robot café platform called as MIXX. Coming built with the RB series of collaborative robots, the platform allows users to operate unmanned café letting the robots take orders, clear bills, make and serve various beverages and foods.

Looking forward, the company is also betting on logistics market, embarking on developments of logistics robots that can pick, carry, and place goods moving all thew way through the warehouse delivery system. On the top of that, the company has recently showcased its dog-shaped quadruped surveillance robot system at Smart Factory + Automation World 2021, a three-day trade show that runs from Sept 8 through 10 in Seoul.

Rainbow Robotics’ competency lies in its ability to produce core components in-house, including actuators, machines, encoders, breakers, and robot controller system.

True enough, Korean e-commerce retailers begin to modernize and upgrade their warehouses and logistics system ballooning demand for the same day delivery of everything from clothes to apparels to footwears to foodstuffs to electronics gears to dairy products and stationeries to miscellaneous. That digitalization of the logistics system will spur up demand for robotic equipment, opening up new market opportunities for robot manufacturers.

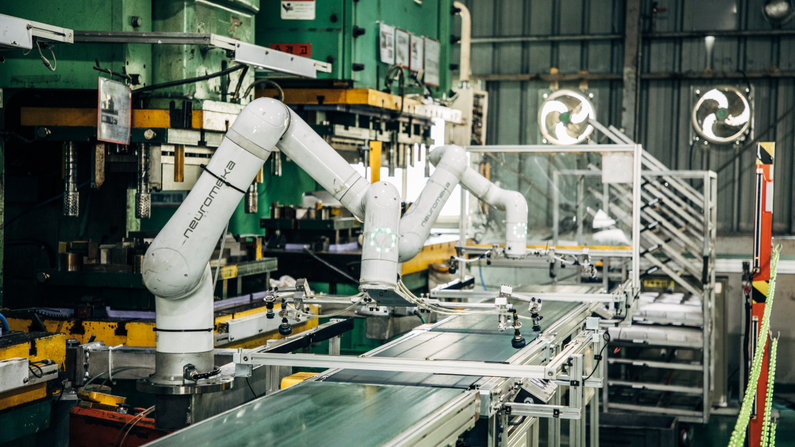

Neuromeka is also angling to capitalize on the growth prospect, aiming to cash in on small-and medium-sized manufacturers’ attempts to digitalize their manufacturing lines.

Same Day Delivery

The robotic maker has a variety of collaborative robot models from its flagship “Indy” series of robot arm system to “Moby” series of autonomous moving robot, or AMR to “D” series of delta robot for assembly lines and logistics system.

All of these robot models are built with its own core components like robot controller units, smart actuators, robot software system and even mobile apps.

With all these key building blocks and innovative robot models, Neuromeka is now trying to create RaaS or Robot as a Service business platform ecosystem to help improve productivity across all manufacturing assembly lines.

For example, its Indy robot arm system is a sort of collaborative robot to work together with assembly line workers. As it comes built with a collision detection algorithm, it can safely work together with human workers. The robot also can be programmed easily both online and offline with a tablet PC-based app.

The Moby series of robots come built with LiDAR ad 3D sensor to move around factory floors and warehouses not only to carry goods, but also guide guests or make a patrol.

The D series of delta robot is a sort of 4 axis parallel robot that come built with multiple kinematic chains connecting the base with the end-effector. As it can pick goods or products in group and then place them in container, its applications vary from packaging to high-speed logistics system.

Neuromeka’s robot series are deployed across a wide variety of applications from factory floors to warehouses to restaurants.