ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

NITTOKU Taps New Markets, Eyes New Business Pitch

NITTOKU Co., Ltd. has been expanding its global business to become a precision factory automation (FA) engineering company. The company has recently implemented what it calls Blue Lake strategy, an approach leveraging open innovation and connections, while addressing these needs with conventional technologies and know-how.

The purpose of this strategy is to deepen its business in existing business domains and explore peripheral domains.

NITTOKU manufacturers automatic coil winding machines used in diverse fields, including motors, transformers, speaker voice coils, and sensors. In Q1 (April to June 2021) of FY2022, the company posted substantial increase in income and profit, with sales of ¥5.531 billion (US$50.2 million), increasing 37.5 percent from the same quarter of last year. Net profit meanwhile pegged ¥443 million (US$4 million), for a 4.5-fold increase on the year.

For the whole fiscal year, NITTOKU expects sales of ¥26.8 billion (US$243.81 million), an increase of 21.6 percent on the year; operating profit of ¥2.6 billion (US$23.65 million) or an increase of 91.7 percent on the year; and net profit of ¥1.85 billion (US$16.83 million), for an increase of 48.3 percent on the year.

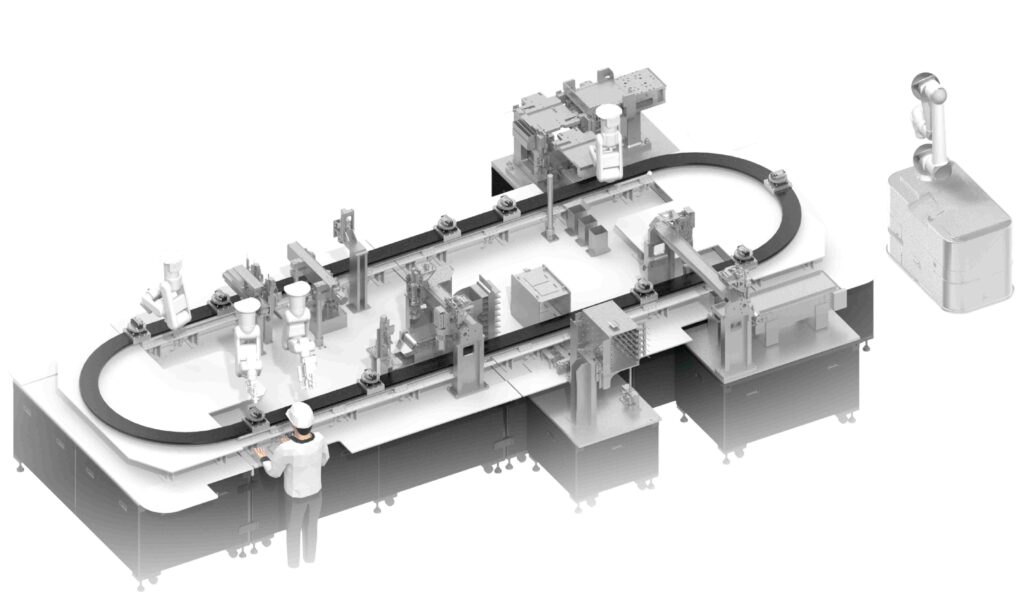

Five years ago, NITTOKU developed in-house the linear index transfer system (LITs) for production lines by applying the core technology of automatic coil winding machines. This time, the company has commercialized FLEX-1 FA platform by further advancing the LITs. Using the platform as the base, the company advances with open innovation with unique companies that own original technologies and manufacturing know-how.

Open Innovation With Unique Companies

Nobushige Kondo, President of NITTOKU Co., Ltd. says, “It is difficult for Japan’s small- and medium-size companies to survive the global competition on its own. Opportunities for small- and medium-size companies lie in the promotion of Blue Lake strategy through open innovation with unique companies that have original technologies and manufacturing knowhow.”

Blue Lake strategy aims to create new markets and seek untapped markets in the regions. The strategy came from the business book Blue Ocean Strategy co-authored by Professor W. Chan Kim and Professor Renée Mauborgne of INSEAD business school. Contrasting blue ocean is red ocean, which indicates existing markets where many companies enter and conditions to fight over limited demand continue.

As part of open innovation, NITTOKU collaborates with Furukawa Electric Co., Ltd. Combining Furukawa Electric’s fiber laser technology and NITTOKU’s FA total control technology, led to the commercialization of laser welder for motors for electric vehicles (EVs) and constructed a production platform for the EV motors. Kondo says, “In Japan, there are many companies with superior element technologies. To enhance added values of these technologies, it is indispensable to combine technologies owned by respective companies, rather than pursuing single company’s technologies. It is important to provide those technologies as systems that meet the needs of global market, instead of proving individual products.”

“Regardless of the company size, companies that have strengths in lakes and companies with strengths in ponds collaborate to construct a business model that is strong in both lakes and ponds, whereby these company can win in the global market. The collaboration with Furukawa Electric is part of the blue lake strategy. We would like to cultivate both lakes and ponds by combining Furukawa Electric’s materials, such as wires, and our company’s production system,” notes Kondo.

Expands FA Business

FLEX-1 FA platform is a modular transfer system for production lines, which adopts a linear motor. NITTOKU has collaborated with Yamaha Motor Co., Ltd. and adopted Yamaha Motor’s linear conveyer module. The modular transfer system operates as variable-mix, variable-volume production, and dedicated mass-production lines by combining various production equipment, including SCARA robot, multiple-axis articulated robot, dispenser, measuring instrument, and vision system. By attaching IC tags to objects for transfer, production history data and other information necessary in the objects.

To expand the FA system business, NITTOKU has already augmented the production at Fukushima Factory in Japan’s Fukushima Prefecture, which is the company’s main factory, and Nagasaki Factory in Nagasaki Prefecture. The company has also increased production in China, establishing a new production base in Changzhou, expanding bases globally. The company also plans to make an inroad into Mexico, where major Japanese automakers are operating.