ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

NTT Data Partners With NVIDIA, FANUC on Digital Twins

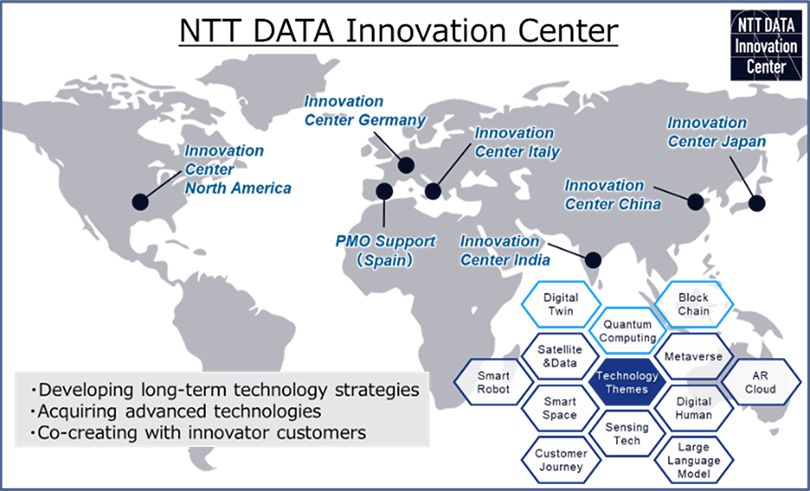

NTT DATA‘s Innovation Center*, established last August, aims to introduce emerging and growth digitalization technologies. For example, Digital Twins applied in the industrial metaverse for businesses and industries.

Most importantly, the center aims to generate new business opportunities by collaborating with clients on joint research and project development. Also, it explores how technology can transform society in a pragmatic way. Particularly, by making emerging and complex technologies transparent and useful for solving everyday problems. The EMEAL center is one of Innovation Center’s six global centers and has strong ties with all centers.

Partnership Details

Several innovative solutions have been developed using Digital Twins in various domains. For example, for a media customer, NTT DATA created a virtual replica of a data center that can be synchronized with the real ones to monitor various KPIs and. Most importantly, to simulate different what-if scenarios.

Now, NTT DATA, specifically the teams of DACH and Italy, is collaborating with NVIDIA to realize various industry-specific use cases.

For an automotive OEM

NTT DATA has developed an enhanced Product Configurator solution. That is, connecting two phases of the automotive value chain, Design, and Presales. This will enable customers to dynamically configure their desired car with all the features and options available for the specific model.

With this use case, NTT DATA can provide a solution for its customer’s challenge to enable the manufacturer to sell highly individualized products. Particularly, through direct channels such as the internet. With the help of a Digital Twin, customers almost get the same “look and feel” customer experience as a visit at the local car dealer would provide.

For manufacturing customers

NTT DATA partnered with FANUC Deutschland GmbH – an expert in automation products and services such as robotics and computer numerical control wireless systems. The project leverages the simulation and photorealistic rendering capabilities of NVIDIA Omniverse. Specifically, this is a platform for connecting and developing Universal Scene Description (OpenUSD)-based tools and applications.

The platform allows enterprises to connect their 3D applications and tools for creation and collaboration, 5G connectivity, and AI algorithms.

The customers benefit from the fact that via NVIDIA Omniverse, the FANUC robot arm can be controlled remotely on a common platform that potentially can also connect other robots and machines – independently of their original product-specific language.

Another added value is that a Digital Twin of the physical robotic arm can be tested and configured in a purely virtual environment. This way, countless variants and parameters can be tried out without potentially harming the real-world production environment. Thus, manufacturers would be able to plan the optimal set-up and configuration of their assets or simulate how different robots and machines interact. This is all in a fraction of the time and costs that usually are needed. NTT DATA’s objective is to show how existing production sites can be optimized and step by step virtualized to create a highly flexible and extremely resource-saving future “i-factory.”

Technical aspects

The project applies computer vision techniques to a 5G camera that captures real-world information. For example, the position and orientation of objects (in this case, brick toys), which the robot will pick up. The outcome showcases the importance of the Digital Twin for industrial robots, as it can optimize their performance, efficiency, and safety, as well as enable new scenarios for remote control and maintenance.

The NVIDIA Isaac Sim platform has been leveraged as a part of NVIDIA Omniverse to create and simulate the Digital Twin of the robotic arm. By using Omniverse technologies (e.g., Action Graph, extensions), a connection to the FANUC proprietary platform has been implemented. This will simulate and execute the pick-and-place task with high accuracy and efficiency.

Artificial intelligence and computer vision techniques play a fundamental role in analyzing the captured images. In addition, in determining the position and orientation of each object, as well as its color and shape. Then, information is sent to the Digital Twin via 5G connection, which allows the Digital Twin to simulate the same scene on its virtual table.

Additional Reference: NTT DATA Launches Innovation Center in Six Countries