ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

NSK, TOPPAN Edge Tap RFID Tags in Condition Monitoring

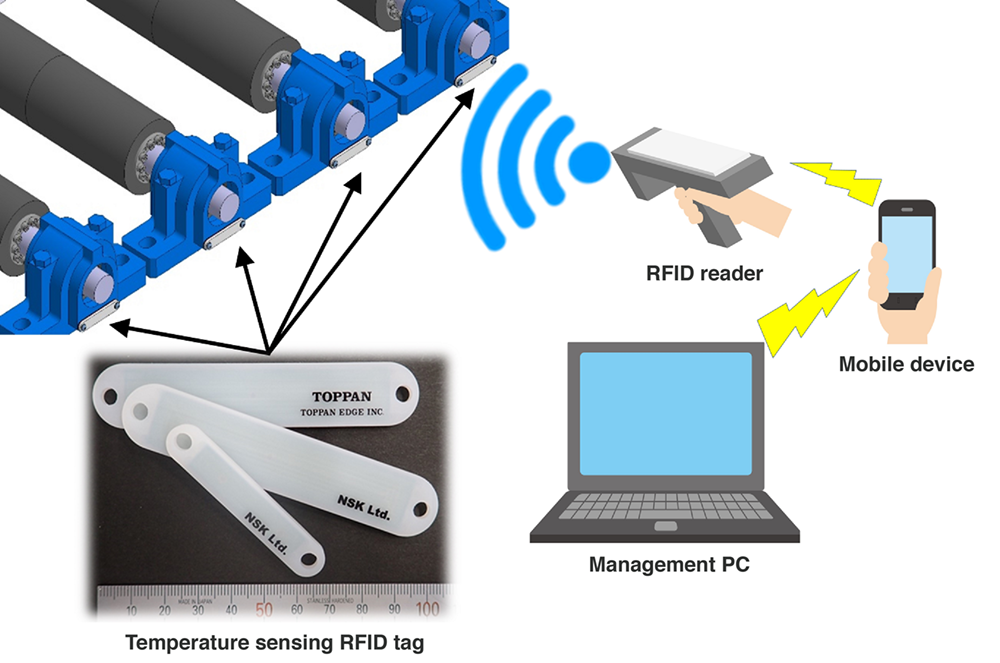

NSK Ltd. and TOPPAN Edge Inc. have started joint development of a maintenance management system for industrial machinery and equipment. Particularly, by exploring the use of temperature-sensing RFID1 tags.

The new product will be exhibited at the iRex 2023 International Robot Exhibition at Tokyo Big Sight from November 29 to December 2, 2023. In addition, the product will take the spotlight at the IPF Japan 2023 International Plastics Fair at Makuhari Messe from November 28 to December 2, 2023.

System Overview

This system consists of a temperature-sensing RFID tag that can be attached to industrial machinery and equipment. In addition, it also has an RFID reader compatible with the tag. Finally, it also has a system that can manage and analyze the acquired data.

The temperature-sensing RFID tags can be attached near the bearing or linear motion products. Next, the RFID tags can be scanned while the machine is in operation to obtain necessary information such as current temperature. Moreover, multiple tags in an area can be scanned at once, making the system easy and efficient to use.

By combining NSK’s expertise in industrial machinery and equipment with TOPPAN Edge’s RFID tag design technology, we aim to realize a new maintenance management system for industrial machinery and equipment, improve work efficiency by visualizing the inspection/maintenance history of industrial machinery and equipment, and increase the efficiency of preventive maintenance by making it possible to check maintenance history and temperature trends on site. We will also aim to improve the efficiency of preventive maintenance by making it possible to check maintenance history and temperature trends on-site.

Development Background

Recently, there has been a growing need for predictive maintenance. As such, the installation of sensors has become necessary to monitor the condition of machinery and equipment to prevent problems before they occur.

Periodic inspections and preventive maintenance have conventionally been performed manually at production sites. Thus, preventing problems with machinery and equipment. However, these tasks require a great deal of resources.

NSK and TOPPAN Edge aim to streamline maintenance inspection and analysis operations and contribute to reducing maintenance workload and further improving safety.

Features

No battery, temperature sensing RFID tag compatible with metal surfaces2

It is possible to read the newly developed RFID tag even when subjected to radio interference from metal surfaces of industrial machinery and equipment3.

Temperature sensing utilizes a passive design4, which enables wireless supply of power from the reader. The RFID tag requires no battery. Therefore, there is no need to manage or change batteries.

In addition, the unique antenna design and optimized board configuration make the reader compact so it can be attached anywhere.

Automatic recording of inspection and maintenance history

The maintenance management system enables quick and easy maintenance record keeping. Furthermore, the data acquired by the RFID reader can be registered. Thus, allowing customers to track inspection and maintenance history and temperature trends of each machine, ID, or product number. Also, it can record the date of start of operation as well as other data.