ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

NSK's New Platform Propels Condition-Based Diagnosis

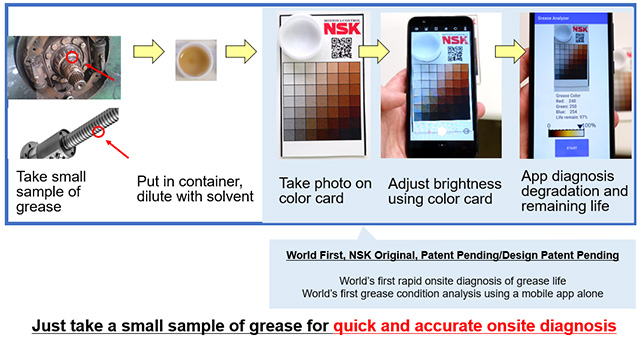

NSK is developing a mobile app applying its newly developed method to rapidly diagnose the remaining life of lubricant grease. Particularly, the app will enable a rapid, high-accuracy onsite analysis of grease condition.

NSK is seeking customer input and feedback on the system to accurately reflect customer needs in the app. Thus, aiming to officially launch the service in 2025. This service will contribute to reduced grease inspection and grease replenishment costs and the implementation of condition-based maintenance.

NSK will exhibit this technology at IPF Japan 2023, an international plastics exhibition to be held at Makuhari Messe from November 28 to December 2, 2023.

Background

(1) Trends in Maintenance Strategy

A wide range of machinery and equipment, such as machine tools and railcars, incorporate grease-lubricated products such as bearings and linear motion products (e.g. ball screws and linear guides). Grease degrades over time as machinery operates, so onsite grease inspection (diagnosis of grease condition and grease replenishment) is essential for stable operation.

Recently, companies have begun shifting their equipment maintenance strategy from time-based maintenance to condition-based maintenance. Accordingly, there is a need for a grease degradation diagnosis method that can be rapidly performed onsite with high accuracy. These optimized, more efficient operations are also necessary to combat labor shortages and to support carbon neutrality efforts.

(2) Current Grease Degradation Diagnosis Methods

Currently, high-accuracy diagnosis methods require laboratory analysis, which is not widely available due to high cost, inability to be used onsite, and the long time it takes to obtain measurement results. As a result, visual observation or densitometer are the common methods to use. However, these methods suffer from low accuracy.

(3) Customer Pain Points (Redundant Labor Costs and Excessive Grease Replenishment)

Moreover, since there is no highly accurate diagnosis method, there is a need to frequently conduct grease inspection and replenishment. Customers have voiced the need to reduce such redundant labor and grease replenishment costs.

Although grease replenishment should be performed based on the results of high-precision diagnosis, there is a need to replenish grease often to ensure stable operation. Thus, resulting in wasteful grease usage.

(4) NSK Expertise in Grease Technology

NSK has a history of more than 40 years of in-house grease development and has developed this new technology to diagnose remaining grease life based on a deep understanding of the chemical makeup of greases. Moving forward, NSK is seeking customer input and feedback to accurately reflect customer needs in the ongoing development of the app.