ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Yaskawa Cell Simulator to Realize Digital Twin

Yaskawa Electric Corporation has announced the development of the YASKAWA Cell Simulator (YCS). Specifically, this is an engineering tool based on simulation verification that adapts to the cell area. This comes following the development of the YASKAWA Cockpit, a visualization tool, and the YRM-X controller, an integrated controller for cell areas.

Since 2017, Yaskawa has been offering the i3-Mechatronics. It is a solution concept that utilizes digital data in addition to automation using mechatronics products. Among them are robots and servo drives. This was developed to realize a new industrial automation revolution.

Purpose of Launch

In a manufacturing site, the improvement of production efficiency is imperative. Also, the variant and variate production as well as shorter cycles of facility renewal are necessary. These are all achieved by diversifying and increasing the speed of market requirements. Especially, in the production equipment, the following three points are required.

1) At the production preparation phase: minimizing the process to consider the design, facilitating setup and adjustment operations, or reducing lead time for equipment installation;

2) At the production operation phase: increasing operation rate, reducing maintenance downtime or reducing robot pause time as well as facilitating switching/changes;

3) Strengthening the ability to respond to frequent cell redesigns, such as by adding or changing new varieties or changing equipment configurations.

Yaskawa meets these challenges by offering an autonomous decentralized cell that makes it easier to build and improve cells. Also, it can enable flexible production facilities that can easily accommodate model addition and volume changes. Specifically, Yaskawa has commercialized an engineering tool for cell areas that can be completely engineered. It utilized a virtual environment, from design to launch, to checking the operation of the entire cell, to analyzing and redesigning the operation, to build this “autonomous decentralized cell “. YCS can contribute to solving various challenges at each phase of the cell system.

Product Features

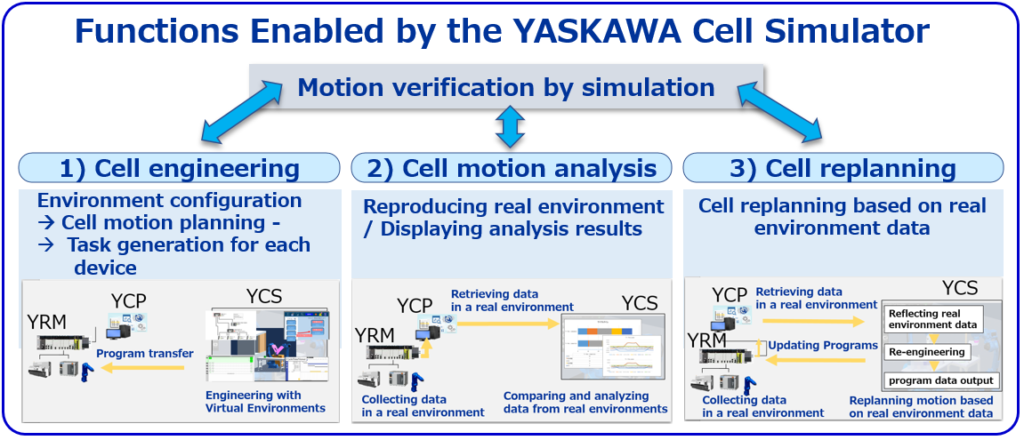

The Yaskawa Cell Simulator features cell engineering, cell motion analysis, and cell replanning.

1) Cell engineering

In cell engineering, YCS examines and determines the structure of cells in a virtual environment. Thereby, it reduces the process of designing cells and sets them up in manufacturing sites. In addition, it sets up an autonomously decentralized cell system based on the data, from engineering work to verifying the operation of the entire cell, all in one place in the virtual environment.

More specifically, it is equipped with A) functions to support the connection settings of devices in a cell, the settings of information boards (a system in which autonomous devices in a cell share data), and the layout settings of devices; B) functions to create and edit cell action plans; C) functions to create and edit programs for tasks that each device performs for a specific purpose; and D) functions to verify the simulation of the entire cell. This enables the minimization of redesign procedures and the facilitation of setup and adjustment tasks in a cell system.

2) Cell motion analysis

In cell motion analysis, users can use the “ideal planning data created in a virtual environment” and “actual data collected and retrieved from a real environment” to effectively analyze the cause of the variance based on the data between the plan and the actual. This function enables users to compare and analyze the time series data of the real environment obtained through YASKAWA Cockpit (YCP) and the ideal time series data created in the virtual environment of YCS. Thus, they can replan for motion optimization and early detection of abnormal causes.

3) Cell replanning

It can also support engineering efforts during the setup and replanning phases of a cell system. It is feasible to perform the same work as engineering in a real environment by using a virtual environment and cell engineering functions that are reconstructed using data from a real environment and have small differences from the real environment. In addition, verification like the real environment as a digital twin is possible by simulating the response performance of peripheral devices. This engineering environment enables analysis and replanning of cycle times by rotating PDCA cycles using data collected in real environments. In this way, cell systems can reduce downtime for maintenance, reduce robot pausing time, and facilitate switching and changing processes.

3. Sales plan

It will be available from Japan in December 2023, and in other regions in sequence.