ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

I-PEX Releases New Board-to-Board Power Terminals

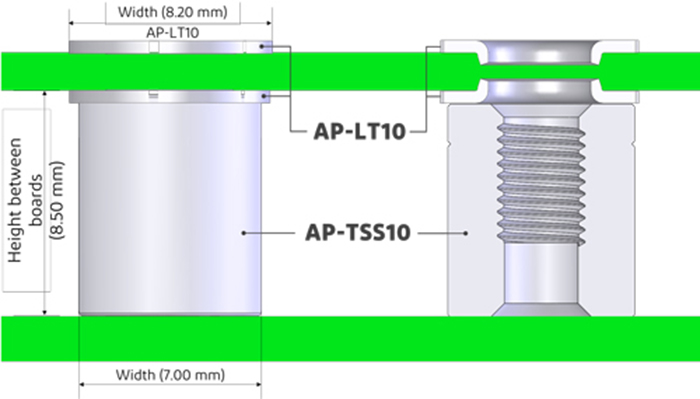

I-PEX Inc. has made available two new products in the AP Series board-to-board power terminals for in-vehicle chargers, inverters, and converters. Specifically, the new terminals are the AP-TSS10 power terminal and spacer for high-current and high-temperature environments and the AP-LT10 lug terminal*.

*Lug terminal: A power terminal, mounted onto a board, solders and connects leads to components with screw-type terminals.

The AP-TSS10 and AP-LT10 have been on sale since late November 2023.

Development Background

In recent years, the automotive industry has been steadily shifting from gasoline and diesel vehicles, mainly powered by fossil fuels, to electric vehicles (EVs). Specifically, EVs require more space to store large-capacity batteries to extend vehicle cruising range.

The AP Series is a series of small board-to-board power terminals compatible with high currents. The series suits key EV components such as in-vehicle chargers, inverters, and converters. It contributes to smaller in-vehicle chargers with higher outputs and larger battery capacities.

Features of New Products

Mainly, in the development of AP-TSS10 and AP-LT10, the company changed the material and structure of AP-10, the first product in the AP Series. Also, both products are compatible with higher currents (32A) and higher temperatures (125°C) environments.

Mounting of AP-TSS10 onto a board is through SMT while mounting AP-LT10 is by reflow soldering onto the surface and bottom of the through-hole of the other board. The final board-to-board connection is made by tightening the screws from above after mounting both terminals. Using AP-TSS10 and AP-LT10 reduces damage to the boards during the screw connection.

In-vehicle applications are becoming smaller and more sophisticated. Accordingly, boards have become denser. Also, it has become more common to mount components on both sides of boards. To secure components, reflow soldering is done when mounting components on both sides – once in the front and in the back of the board. When flipping the board during the second reflow, the solder may melt. This may lead heavy components to drop due to their own weight or to cause mounting defects.

AP-TSS10 uses aluminum as its base material and is about 67% lighter than conventional metal spacers that use brass. This enables stable mounting on the back. Moreover, it contributes to better flexibility in board design and denser boards.