ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New SMT Solutions Allow End-to-End Optimization

ASM Assembly Systems has introduced a range of new solutions that promote process improvements across the entire surface mount technology (SMT) line for an end-to-end optimization. Among the salient features of the solutions are the ability to integrate systems from other manufacturers.

During the ASM Impact – Release Summer 2021 livestream event held in Munich, Germany, ASM also focused on the new functions of its ASM Works shop floor management suite.

Jérôme Rousval, SMT Solutions Manager at ASM, noted the crucial weak spot of many SMT production solutions is its ability to focus only on individual process steps. He said ASM’s latest solutions open up completely new process improvement possibilities for users.

“Printers and SPI systems, placement machines and AOI solutions as well as reflow ovens and post-reflow AOI systems form only so-called closed loops. Since ASM focuses on breaking up these operational silos, we are developing holistic solutions that enable process optimization across the entire line from printing and placement to reflow and that also include systems from other suppliers,” said Rousval, who is also a specialist for inspection technologies and manufacturing optimization.

End-to-End Traceability

The first of the many solutions ASM Impact – Release Summer 2021 introduced is the DEK All Purpose Clamping (APC), ASM’s universal and flexible clamping system for printing solutions. Now available for the DEK TQ high-performance printer, users can choose the most suitable clamping method for each task. This includes top side clamping for warped boards, automatic adjustment to the PCB’s thickness, and control of the clamping pressure.

Users can save time during setup changeovers and minimizes fault rates because they can save parameters and retrieve later for subsequent production jobs.

By supporting the IPC Hermes 9852 standard, the DEK TQ delivers end-to-end traceability across the entire line. The Long Board Option for the DEK NeoHorizon gives manufacturers even more flexibility as it can handle boards that are up to 620mm long. The DEK Typhoon understencil cleaning system adapts accordingly to enable efficient cleaning of the total print area.

Enable Process Improvements

Rousval said when ASM developed the ASM ProcessLens, the company focused entirely on designing an SPI system with top quality and reliability. He added, “Today, our focus is more on making process improvements, which we developed directly from the feedback of our customers. This allows us to develop new functions and delivering an even better user experience.”

ASM managed to further shorten the cycle times and make the conveyor belt settings more flexible for each individual product. The latest version of the software also now supports multi-threading.

To optimally process the large volumes of data generated during the inspection, they system send these data to the next available processor core so that up to four processes can run in parallel. It is now possible to install the statistical process control (SPC) software of the ASM ProcessLens on offline computers. This makes it possible to analyze data from multiple SPI systems on different lines simultaneously and more features are now available in the offline programming station.

“So far, many users have employed SPI systems only to run a ‘go’ or ‘no-go’ evaluation of printed boards, not to efficiently optimize their processes,” said Alexander Hagenfeldt, Head of Global Product Marketing at ASM.

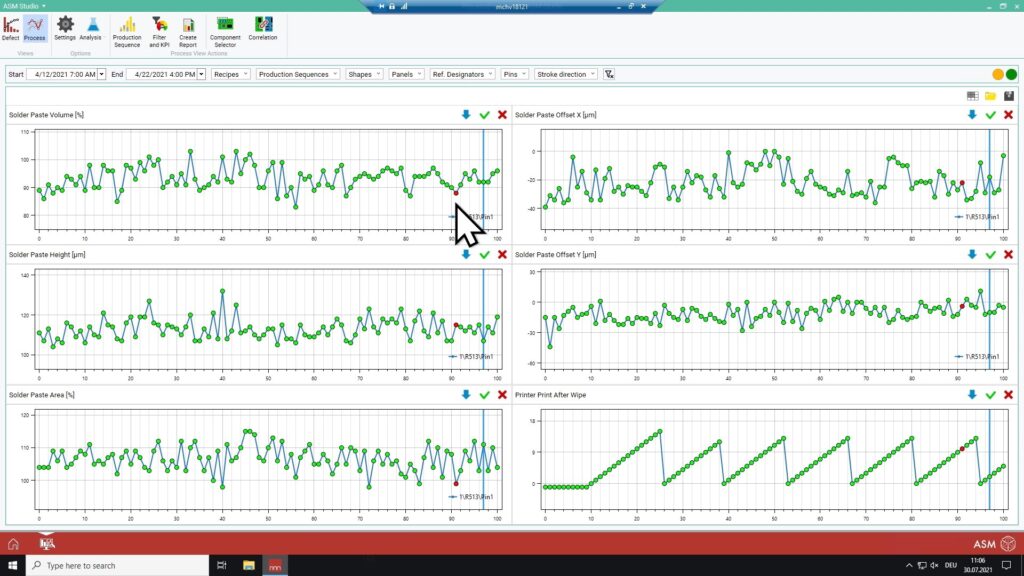

“Since we can capture and evaluate data from the printing and placement processes together with SPI and AOI data in the ASM ProcessExpert and the system can even use the results to make process improvements autonomously, the advantages of our system extend far beyond the normal solder paste inspection,” Hagenfeldt said. He added this gives more options to electronics manufacturer because they can flexibly retrofit these optimization functions.

Expanded Feeding Options

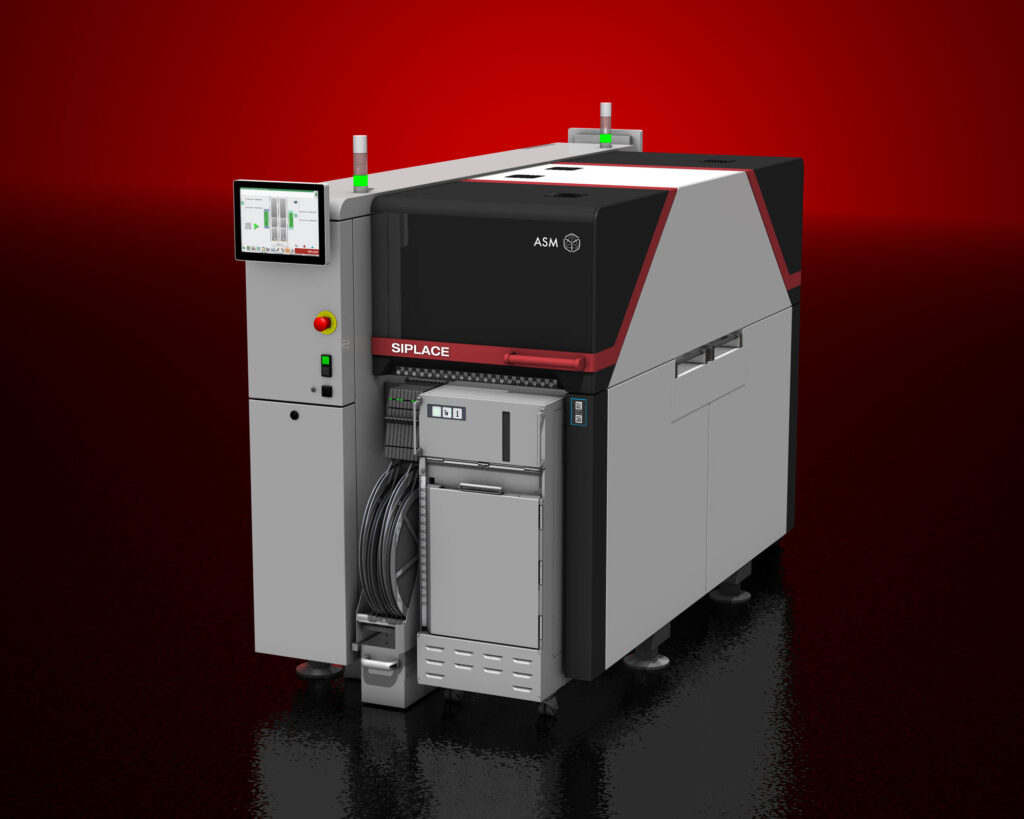

With the SIPLACE Tray Unit presented during the Impact event, ASM has come up with a particularly powerful solution for supplying components in trays to the high-end SIPLACE TX placement solution that makes high-volume production much more productive. The system, which holds up to 42 carriers for up to two JEDEC trays each, attaches to the machine like a standard changeover table. As a special feature, it can accommodate carriers without having to interrupt the operation. Thanks to the slim design, up to ten feeder slots on the SIPLACE TX remain available for other uses, and the unit has a hangover of only 13cm, saving valuable space on the front of the machine.

Also new is the SIPLACE Force Verification Feeder. This option makes it possible to cyclically verify the placement force of each individual nozzle segment and optimize the total placement process as an external verification unit.

ASM Works

The ASM Impact – Release Summer 2021 event placed special emphasis on the ASM Works shop floor management suite. With the ASM Software Equipment Connector, makes it possible to transfer data from third-party solutions into ASM Works. The adapter solution is based on the open IPC CFX standard.

ASM solutions can use this standard to communicate with machines and systems and support it. The adapter also makes it possible to support fault and root cause analyses by integrating AOI systems.

Also new in ASM Works are two modules for the ASM ProcessExpert, the self-learning SPI expert system. The Placement Module automatically sends messages with improvement suggestions to the operators of placement machines. The Quality Viewer module is a tool for quality monitoring, error analysis and root cause identification across the entire SMT line. It correlates process data from DEK printers, the ASM ProcessLens, SIPLACE placement machines and third-party AOI systems and displays them in easy-to-understand charts.