ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

NITTOKU Innovations Drive Manufacturing Excellence

NITTOKU Co., Ltd. is promoting open innovation with unique technologies and manufacturing know-how.

Particularly, the company leverages its strength in two technologies. First, the linear index transfer systems (LITs), which carry the company’s core technology in automatic coil winding machines. Second, the FA platform FLEX-1, a further evolution of the system.

The company manufactures automatic coil winding machines used in various fields such as motors, transformers, speaker voice coils, and sensors.

Nobushige Kondo, President at NITTOKU, said Chinese companies are strong in terms of investment speed and investment amount for individual production facilities. Although many companies in Japan have excellent elemental technologies such as rubbing technology, there is a way to survive the competition by promoting the Blue Lake strategy.

Particularly, Kondo said the strategy is through open innovation, rather than one company to increase the added value of these technologies.

In addition, Kondo said, “As a production line builder that acts as a production technology agent, we want to contribute to the manufacturing industry through collaboration and co-creation.”

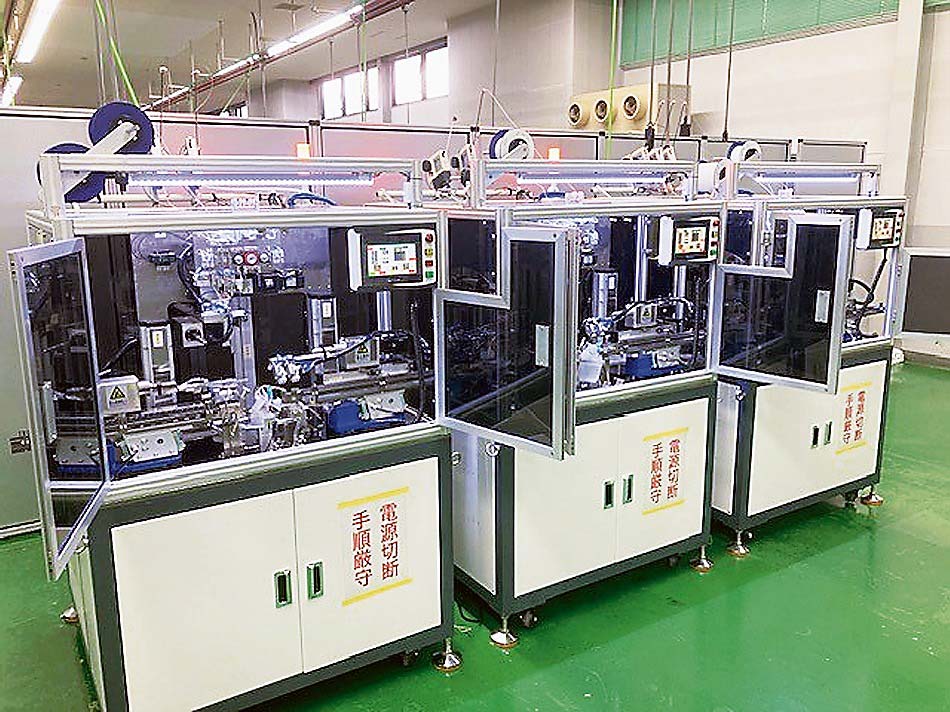

The FA platform FLEX-1 is a modular transport system for production lines that uses linear motors. Its operation is either as a variable-mix, variable-volume production, or dedicated mass production line. Particularly, by combining the system with various production facilities such as SCARA robots, multi-axis articulated robots, dispensers, measuring instruments, and vision systems.

Improves Conventional Process

NITTOKU has been promoting the convergence of LITs and FLEX-1. For example, a recent production platform for laser welding machines combines Furukawa Electric’s fiber laser technology with NITTOKU’s FA total control technology.

In addition, AMADA Press System Co., Ltd. began selling last July a flat copper wire processing system (production equipment line). Particularly, the system has the ES-1A segment conductor coil processing machine for electric vehicles (xEVs).

For EV motors, the method of using flat copper wires is becoming mainstream to increase the size and output of EVs. Moreover, the system combines coil processing technology and the copper material evaluation technology of the MEC spring of the AMADA Press System with NITTOKU’s FA technology. Thus, this method was able to solve the problems of changing and adjusting the shape of flat copper wire.

Originally, this was difficult with conventional processing methods. This is because of the high thermal conductivity of pure copper, which is the material of flat copper wire. Also, the instability of coil molding. Thus, resulting in machining accuracy defects.

The new method has made it possible to improve the efficiency of the motor production process. That is, speed, simplification of the process, and stabilization of quality. Furthermore, the company has developed a transformer coil equipment system that automates the production of transformers for electronic circuits. It uses the company’s multi-function winding machine and FA platform. The functions necessary for transformer production, such as workpiece supply, winding, taping, soldering, appearance, and continuity inspection, go together into a single unit. Moreover, it can flexibly respond to frequent specification changes and changeovers. It also supports multiple mixed productions.

In addition, Kondo said, “Transformers for electronic circuit boards are subject to severe price competition and require innovations.”

Expands Overseas Innovation Centers

NITTOKU is in the process of establishing a new base to expand open innovation overseas. The company has overseas offices in Suzhou, Shenzhen, Dalian, Changzhou, Xiamen, and Shanghai in China; Hong Kong; Taiwan; South Korea; Singapore; Vietnam; Malaysia; India; Thailand; the United States; Mexico; Brazil; and Austria.

Meanwhile, the company has established a new wholly-owned local subsidiary, NITTOKU PHILIPPINES Inc., in the Philippines. As an increasing number of companies are shifting production to the Southeast Asian region due to risk aversion in China, the company will work to expand orders on an all-NITTOKU bases, including in neighboring countries in the region.