ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

ORGANO-CIRCUIT, YELECS Partner on Organic Semiconductor Displays

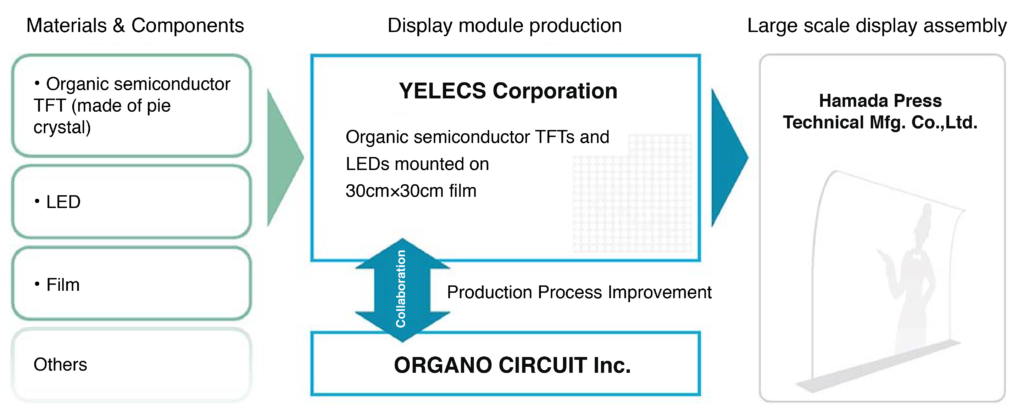

Japanese manufacturers, ORGANO-CIRCUIT Inc. and YELECS Corporation have partnered to mass produce flexible displays using a deposition technology of organic semiconductor single crystals developed by Takeya Laboratory, the Graduate School of Tokyo University. Together, they will develop a mass production line and start full-scale production with production to begin mid-January.

ORGANO-CIRCUIT develops organic semiconductor displays. Meanwhile, YELECS develops and manufactures equipment. YELECS aims for mass production and targets a monthly production of 20 units. In the future, the company plans to produce 300 pieces per month, and if realized, it will be the first to do so.

Unlike general semiconductors, which are made of inorganic materials like silicon, organic semiconductor materials dissolve in a solvent. They can be applied as ink and then printed. Thus, mounting on thin, lightweight, and flexible equipment is possible. The organic semiconductor technology developed by Takeya Laboratory can achieve both a large area and high performance by forming a single crystal. However, issues such as yield and production cost before mass production, remain. Many companies have stopped working on mass production.

Each module of the flexible display measures 30×30cm2. About 10,000 crystal organic semiconductor thin-film transistors (TFTs) measuring 750μm2 and 10,000 LEDs can be mounted on the pattern-printed film. In preparation for mass production, both YELECS and ORGANO-CIRCUIT plan to improve the yield by improving the raw materials and manufacturing process.

This time, PI-CRYSTAL, Inc., a member of the Daicel Group, is jointly developing and commercializing TFTs for organic semiconductors. For its part, YELECS targets mass production, while ORGANO-CIRCUIT will repurpose its display production technology to improve production accuracy.

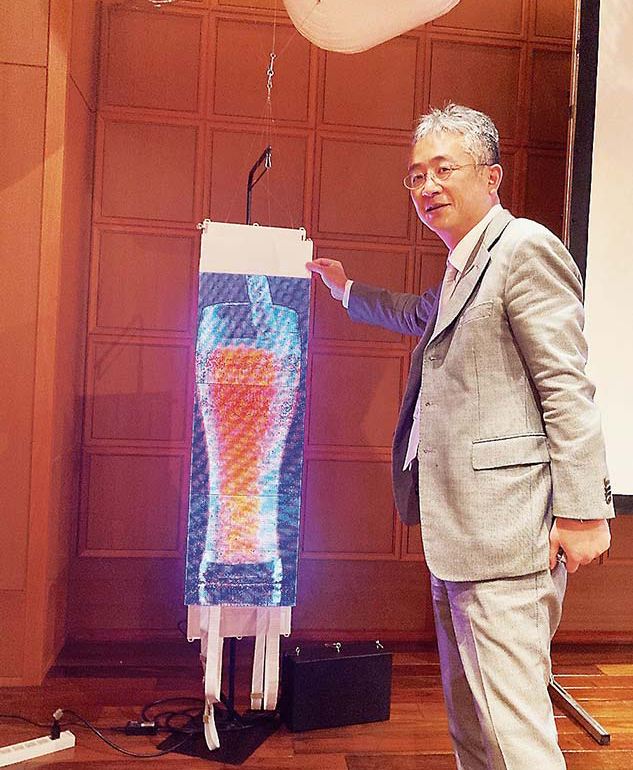

Moreover, the freely stitching the modules together to form a large display is possible. Since they are thin and lightweight, there is no need for huge installation work when installing large outdoor displays. Thus, there are various possibilities of use. Also, Hamada Press Technical Mfg. Co., Ltd. will combine the modules to create a large-scale display.