ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

TE, HDS Collaborate to Improve Functionality of Cobots

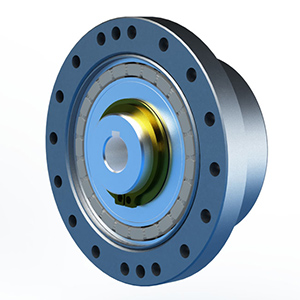

TE Connectivity (TE) and Harmonic Drive Systems Inc. (HDS) have joined forces to develop a new series of HarmonicDrive® gears. Specifically, these gears, equipped with a safety torque sensor, improve the operational safety of collaborative robots (cobots). Mainly, this collaboration aims to meet the rapidly growing demand for cobots across various industries.

Currently, HarmonicDrive® gears are an essential component of automation equipment, robotics and aerospace applications. They play a crucial role as indispensable mechanical transmission device for today’s society. Mainly, the combination of TE’s high-performance safety torque sensor and HDS’s high-precision control speed reducer enables HarmonicDrive® gears to exceed the customers’ expectations. Specifically, they deliver high-precision torque sensing, lightweight design, compactness, and a spacious hollow structure.

The collaboration achieved high reliability and safety for collaborative robots resulting from the following key features:

- The design structure aims to reduce the applied cross load on the safety torque sensor.

- The safety torque sensor incorporates the trusted MICROFUSED sensing technology known for its reproducibility, long-term stability and reliability. Optimized for collaborative robots, the sensor also exhibits low susceptibility to crosstalk.

- The safety torque sensor complies with the new level of safety requirements specified in ISO13849 Category 3 PLd. Meanwhile, this module is also certified at the component level, simplifying the process of obtaining safety certification.

- Offering customizable mechanical interfaces, the sensor can be effortlessly tailored to meet specific customer application needs, which significantly reduces development time and facilitates the incorporation of high precision into the system.

“The surging demand for collaborative robots makes safe operations around humans a must,” said John Tuley, global strategic customers director of TE Sensors. “By delivering heightened accuracy and speed, TE’s Safety Torque Sensors provide functional safety, paving the way for the next generation of human-robot collaboration.”