ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New JAE Connector Features 8A Power Support

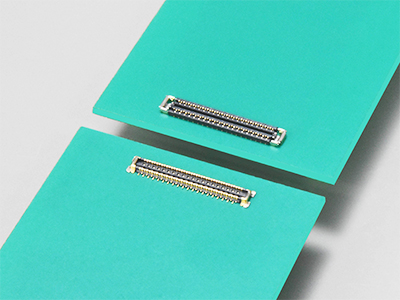

Japan Aviation Electronics Industry, Ltd. (JAE) has developed and released the WP86SD Series compact stacking type board-to-board (FPC) connector equipped with an 8A power supply terminal for compact devices such as smartphones, wearable equipment, and ICT devices, such as gaming PCs. This FPC connector is said to be the first* in the industry.

*As of Dec. 2023, according to JAE research. As a board-to-board connector for compact ICT equipment

Industry Background

In compact devices such as smartphones and wearable devices, circuit boards are becoming denser, leaving less space for internal components such as connectors. At the same time, power consumption is rapidly increasing due to the popularization of USB Type-C fast charging and high speed 5G communication. These trends create a demand for high current support.

Two-layer FPC Compatible Quad-Row Array Connector

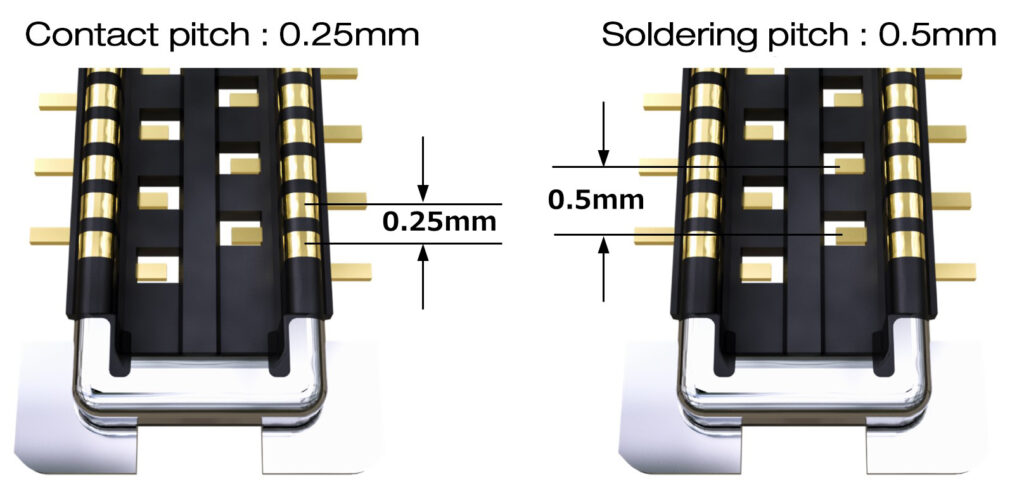

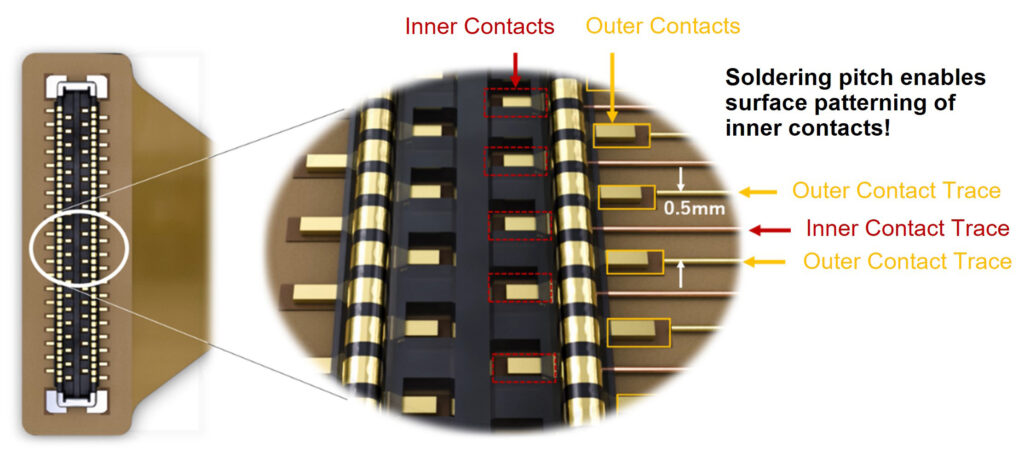

To meet these market needs, JAE has developed and released the board-to-board (FPC) connector WP86SD Series. Specifically, the company achieved miniaturization by adopting a staggered Quad-Row array (4-row array) with a contact pitch of 0.25mm and a soldering pitch of 0.5mm. Also, it was able to employ the industry’s first 8A power hold down terminal.

Specifically, the WP86SD Series uses a Quad-Row array in which the terminal surface mount pads conventionally arranged in two rows are spread into four rows. When the contact pitch is reduced in a Quad-Row arrangement, typically a multilayer FPC is required to route the traces from the inner-row of terminals. As a result, this causes the trace routing to become more complex and significantly increases the cost of the FPC.

To address this issue, this product uses a contact pitch of 0.25mm to reduce the external size of the connector while using a staggered arrangement. Specifically, in a staggered arrangement, the terminal orientation is alternated to the inner and outer row. By doing so, it ensured a soldering pitch of 0.5mm for each of the four rows. In turn, this enables routing of the traces of inner-row terminals in a single layer. The WP86SD Series aims to offer the smallest size product; while at the same time, supporting surface trace routing on inexpensive two-layer FPCs.

Industry’s First 8A Power Supply Hold Down Terminal

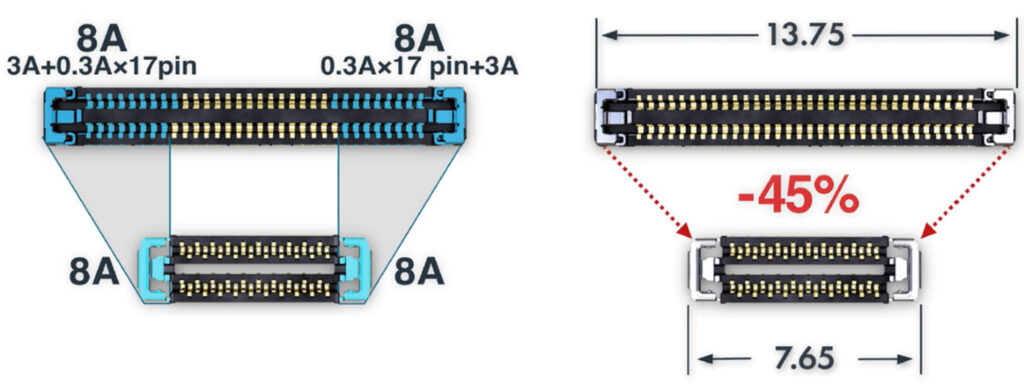

Typically, board-to-board (FPC) connectors of existing products typically only allow 3A of current to flow through the power supply hold down terminal. If the current capacity is insufficient, using the signal terminal is possible to share the current carrying load. However, as this increases the number of contacts in the connector, the space required for mounting also increases.

Additionally, the WP86SD Series features two power supply terminals that can deliver 8A of current. Specifically, this is more than twice the current capacity of conventional products, even though the size is the same. Combined with the Quad-Row arrangement, reducing the length of conventional products by approximately 1/2 is possible (Figure 3).

Moreover, the WP86SD Series features a proven two-point contact structure with high contact reliability. It has a low profile design with a mated height of 0.6mm. Also, it features a full armor structure that prevents insulator damage and improves robustness. An alignment guide feature created by a metal drawing process offers excellent alignment and durability. Further, it exhibits excellent workability with tactile feedback when fully mated.