ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

TEL, HACARUS Unveil AI Tool to Prevent Factory Hazards

HACARUS Inc. has jointly developed a new AI tool to prevent industrial hazards with Tokyo Electron.

Accordingly, HACARUS is showcasing at the ongoing Smart Factory EXPO in Tokyo, Japan the new AI tool. In the future, the product will be continuously improved by responding to customer requests – aiming to put it into practical use as soon as possible.

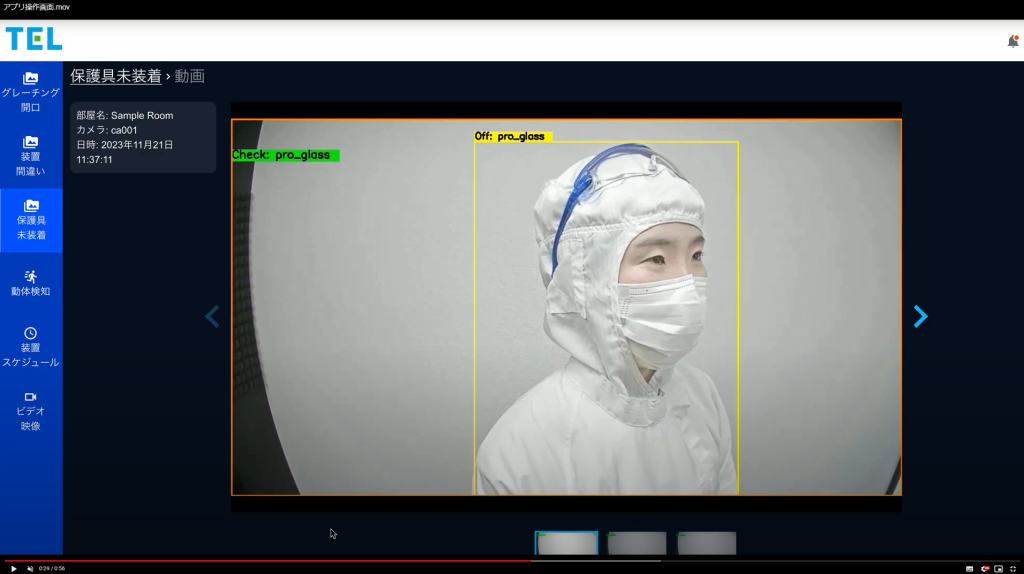

Introducing the Industrial Hazards Prevention AI Tool

HACARUS and Tokyo Electron have developed high-performance edge AI models for incident detection at work sites trained with small data sets. Thus, leading to lower implementation and operational costs.

Enabled by a resource-efficient design, the technology allows model training and on-site. That is, with data staying locally at the customer’s manufacturing location. By combining cameras and AI, this solution enables 24-hour real-time monitoring for incidents. Previously, this has been difficult for human operators.

Operational Flow:

- The manufacturing site undergoes continuous monitoring using a small camera. Particularly, it integrates HACARUS’ AI analyzing the image feed.

- It scans for signs of incidents, hazards, and dangers in real time. Also, it alerts workers and operators when detected.

- The solution can automatically records image feed before and after an alert. Thus, making it possible to check and review the circumstances that led to an incident.

Capabilities Examples:

- Ability to detect latent workplace dangers

- Can detect improper use of protective equipment

- Monitor behaviors, such as workers unsure how to operate equipment

Development Background

In the semiconductor industry, there is a serious shortage of human resources. Particularly, as employment diversifies, ensuring worker safety has become even more important. In addition to designing equipment based on safety, the industry strives to increase the safety awareness of each individual to prevent hazards.

Tokyo Electron maintains high standard in hazard prevention in the industry. In addition, it is also promoting various initiatives for its business partners to prevent incidents. The joint development with HACARUS and application of AI, to eliminate human errors for a safer workplace, is part of this important effort.