ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Yaskawa Controller Promises Better Machine Performance

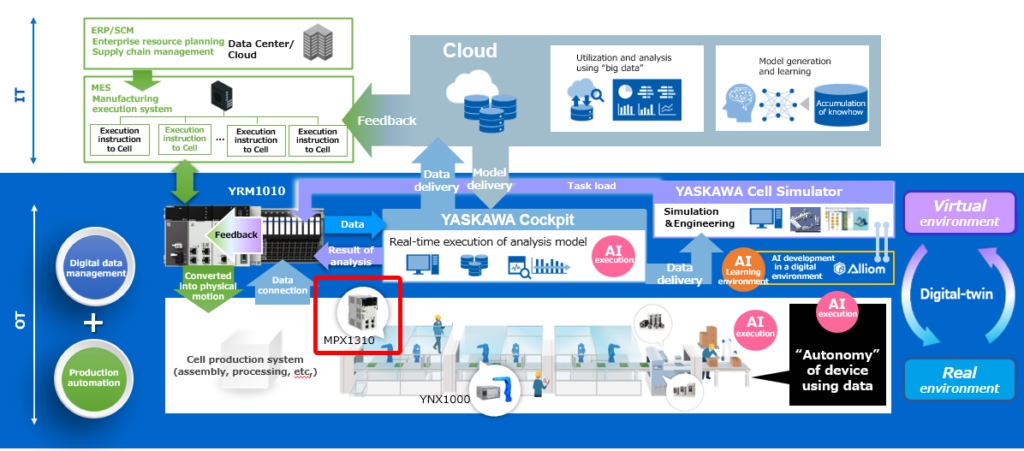

Under the i³-Mechatronics solutions concept, Yaskawa Electric Corporation has been promoting product development to make the concept a reality. Recently, the company released the MPX1000 Series machine controller under the iCube Control controller solution.

In this controller solution, Yaskawa launched the MPX1000 Series, a new machine controller with improved performance and enhanced functionality. Specifically, this new model succeeds the MP3000 Series, a machine controller well-regarded for its controlling equipment. Now, the company released the MPX1310 model as the first product in the series.

The i³-Mechatronics solution adds digital data management to automation solutions, to realize the new industrial automation revolution outlined in the Vision 2025.

Aim of the Commercialization

In response to customer requests for higher speeds in industrial equipment, Yaskawa has expanded its product lineup since it launched major products. Specifically, it released MP3200 in Oct. 2011 and MP3300 in Nov. 2013 as part of the MP3000 Series of machine controllers. This series specializes in high-speed, multi-axis synchronous control of servo drives.

In recent years, in addition to further high-speed control performance, it has been required to increase the number of control axes by integrating equipment functions, connect peripherals, and expand the lineup of I/O etc.

Specifically, the MPX1310 model of the MPX1000 series, which has been commercialized as a successor to the current MP3000 Series, achieves significant performance improvements. Among them include an 8x more motion processing performance and an increase in the number of controllable axes from 16 to 128. Also, the performance of the company’s servo drive products can be maximized. Thereby, it significantly improves equipment performance and added value of customers.

Main Features

Improved motion processing performance

Mainly, the MPX1310 greatly improves processing performance and achieves about 8x the MP3300 CPU-301 ratio. Also, it has two lines of the high-speed motion network MECHATROLINK-4, enabling synchronization control of servo drives with up to 128 axes. In addition, it adopted multi-scanning, making it possible to distribute high-speed control axes as well as low-speed control axes synchronously, thereby contributing to further improvement of equipment performance.

User application compatibility with MP2000/MP3000 series

The existing MP2000/MP3000 Series user applications are also compatible with the MPX1310. Also, MECHATROLINK communication is switchable to MECHATROLINK-III and easily replacable from the MP3000 Series.

Support for SLIO I/O series

Additionally, the MPX1310 supports a wide range of SLIO I/O that can be directly attached to the device to build a versatile system. Also, distribution of SLIO I/O is possible as remote I/O by using bus couplers for various networks such as MECHATROLINK-4.

Support for optimum communication for equipment control

It employs two Ethernet ports and is possible for use in general Ethernet communication as well as Ethernet/IP communication. It supports message communication with various communication protocols. Thus, it is possible to use it easily without requiring any user application.

Main Application Areas

The MPX1310 is ideal for devices that pursue high speed, high response, and control synchronization, as well as devices with several control axes. Among them are:

- Semiconductor Manufacturing Equipment: Mold equipment, die bonder

- Liquid crystal manufacturing equipment: Scriber, seal dispenser

- Electronic component assembling equipment: Chip mounter, solder printing machine

- Metal working machine: Servo press, winding machine, spring manufacturing device

- Industrial robot: Parallel link, horizontal articulation, vertical articulation

- Secondary battery manufacturing: Roll press, separator manufacturing, electrode layer manufacturing