ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Alliance Pushes Next-Gen 3D Printing to New Heights

Nano Dimension Ltd. and Fraunhofer Institute for Manufacturing Engineering and Automation (Fraunhofer IPA) have agreed to collaborate and dig deeper on pushing the boundaries of three-dimensional (3D) printing technology, said Nano Dimension in a statement.

Nano Dimension is a provider of additively manufactured electronics (AME) and printed electronics manufacturing system. Fraunhofer IPA, meanwhile, is one of the largest institutes under the Fraunhofer-Gesellschaft.

Additively Self-Learning Machines

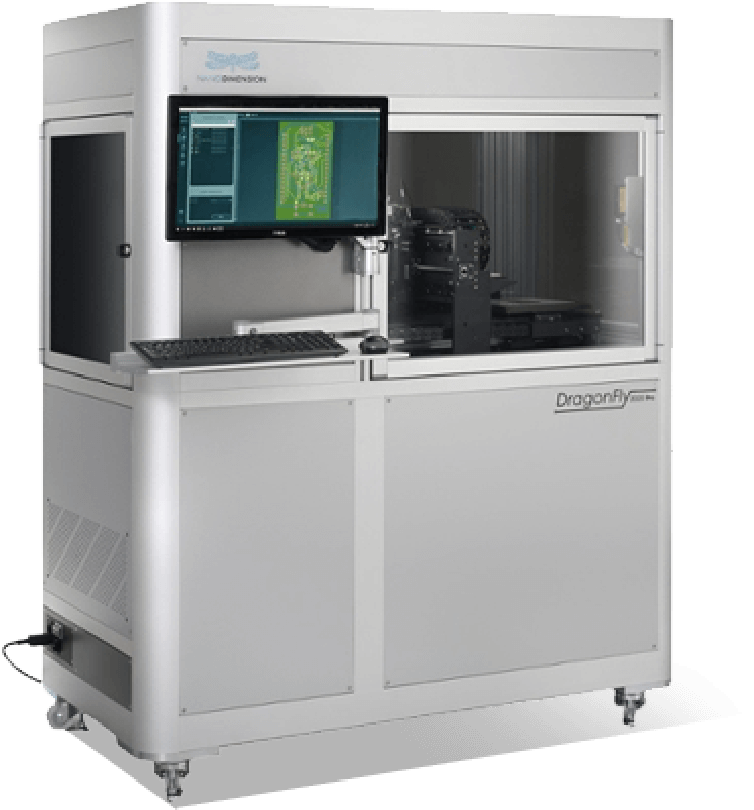

In the two-year collaboration plan, Nano Dimension and Fraunhofer IPA will focus on the research and development within the field of autonomous fabrication of electromechanical systems based on 3D freeform printing and the highest precision 3D assembly technologies. Nano Dimensions said it will integrate and incorporate insights from the collaboration to its DragonFly additive manufacturing system. This, the company said, would benefit existing customers.

Yoav Stern, Chairman and Chief Executive Officer of Nano Dimension, commented, “We are very pleased to have the opportunity to cooperate and learn from the world-class engineers and scientists at Fraunhofer IPA. We can learn from both their successes and failures while contributing our expertise and knowledge as we work together to build an ecofriendly and intelligent distributed network of additively manufacturing self-learning and self-improving machines, which will deliver a superior ROI to their owners as well as to Nano Dimension shareholders and other stakeholders.”

Oliver Refle, Head of the Additive Manufacturing Department at Fraunhofer IPA meanwhile said the collaboration will allow both parties to analyze and improve processes by sharing ideas, data, and expertise. This will be vital, Refle said, with the development of next-generation 3D inkjet printing and create new and better processes and integrations for the ultra-accurate printing of new high-performance electronic devices (Hi-PEDs).

“Nano Dimension is a valued and trusted partner, and we are very excited to begin this new partnership,” said Refle.

Focuses Manufacturing Industry

Founded in 1949, the Fraunhofer-Gesellschaft currently operates 75 institutes and research institutions throughout Germany. Most of the Institute’s 29,000 employees are qualified scientists and engineers, who work with an annual research budget of €2.8 billion.

Of this sum, contract research accounts €2.4 billion. The focus of Fraunhofer IPA’s research and development work is on organization and technological issues related to the manufacturing industry.

Their fifteen specialist departments focus on twelve major research areas, including: frugal manufacturing systems, artificial intelligence (AI) in manufacturing, lightweight engineering and functional coatings, and additive manufacturing technologies.

Through a European Union (EU)-sponsored project – NextFactory – Fraunhofer IPA previously created a modular printing system processing conductive and dielectric material, as well as support material, in combination with a pick and place process and an online quality inspection.