ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Yaskawa Bus Coupler Improves Data Collection in Smart Factories

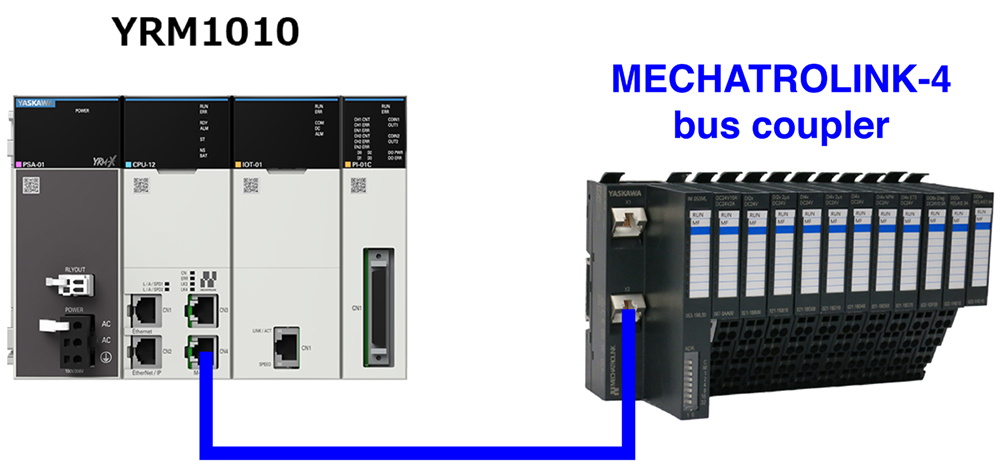

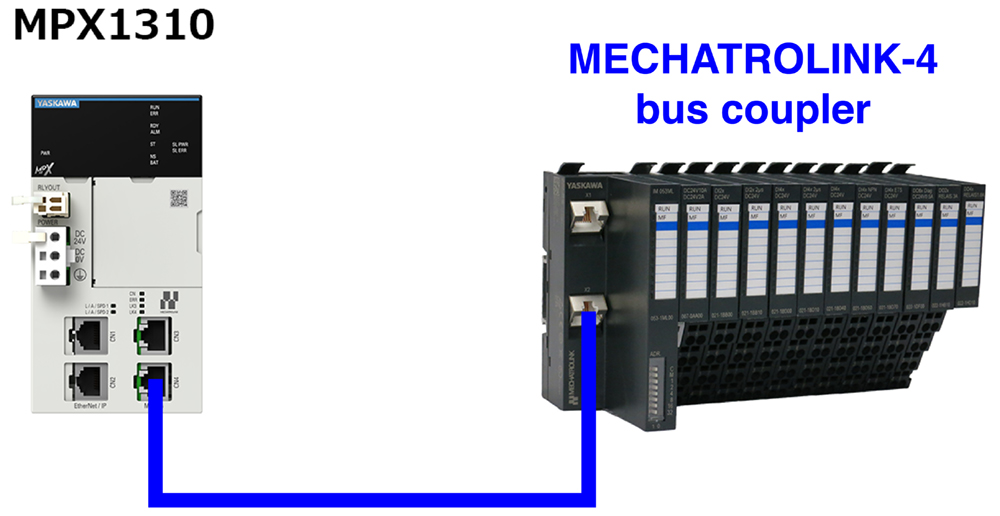

Beefing up its product lineup under the i³-Mechatronics concept, Yaskawa Electric Corporation has launched the MECHATROLINK-4 bus coupler*. Specifically, it supports the MECHATROLINK-4(M-4) high-speed motion network that further improves data collection performance.

*A bus coupler is a range of dedicated modules for connecting to various networks.

Yaskawa announced the “i³-Mechatronics” solution concept in 2017, which adds digital data management to automation solutions. Specifically, this aims to realize the new industrial automation revolution outlined in the Vision 2025. Over the years, Yaskawa has been enhancing product development to make this concept a reality. In relation, Yaskawa has developed a controller solution iCube Control to realize i³-Mechatronics. Also, it has put to market the SLIO I/O Series, an I/O product to input and output data for connecting to various equipment such as factories and production facilities. This time, the company has launched the MECHATROLINK-4 bus coupler.

Aim of Commercialization

Various manufacturing sites are accelerating efforts to advance smart factories by improving production efficiency and quality, utilizing IoT and AI, as well as ensuring traceability. The basis of these activities is understanding the operating status (data) of production facilities. Yaskawa started sales of the MECHATROLINK-4 bus coupler, a new M-4 compatible I/O product in the SLIO I/O Series, which efficiently and stably collects data from factories and production facilities. This expands the range of system construction using the M-4 network and enables data collection tailored to customer needs.

Main Features

1) Improved data collection performance

Compared to the conventional MECHATROLINK-III bus coupler, the size of data obtainable per transmission cycle in MECHATROLINK-4 is approximately 1.7 times larger. Accordingly, this enables faster and more efficient data collection.

2) Extensive lineup

Also, the new bus coupler offers a broad lineup with more than 90 modules. This includes digital I/O and analog I/O products, thus, enables flexible system construction. Additionally, up to 64 modules can be attached to the bus coupler for network connection. Customers can use line extension modules to divide a single wire into up to five lines.

3) Connection function for saving space

Space saving can be realized by screwless terminal and stair shaped wiring.

4) Easy installation and maintenance

No screws or special tools are required for assembly. Also, replacement is only possible by the electronic module after installation and wiring, so it can be maintained quickly.