ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Valiant TMS Taps Realtime Robotics' Optimization Solution

Realtime Robotics, the leader in collision-free autonomous motion planning for industrial robots, has partnered with Valiant TMS, a full-service Industry 4.0 system integrator, to optimize manufacturers’ productivity. Specifically, Valiant TMS will apply Realtime Robotics’ innovative Optimization-as-a-Service solution to customers’ manufacturing operations.

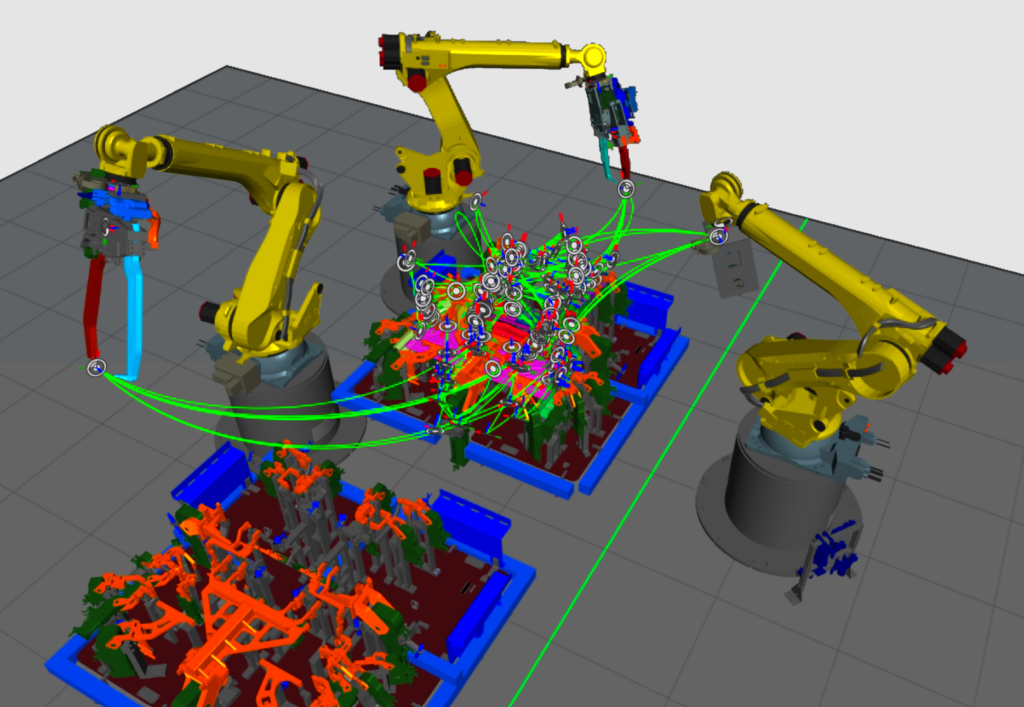

The combination of Valiant TMS’ years of manufacturing industry expertise with Realtime Robotics’ proprietary optimization software and experienced robotics engineering insights presents customers with an easy way to improve the efficiency and productivity of their automation operations. Realtime’s solution rapidly generates and tests hundreds of thousands of potential robot paths. Accordingly, it determines the best motion sequences based on target sequences, robot reach, and other customer-desired parameters.

In fact, in a recently completed multi-robot application, Valiant TMS used Realtime’s optimization solution to design motion plans with more efficient motion paths, better interlocks, and a faster execution time. Ultimately, it reduced a customer’s robot cycle time by 17% and cut robot programming time in half.

“Our collaboration with Realtime Robotics is very interesting and trendsetting,” added Michael Schaubmayr, Group Manager, Mechanical Engineering Simulation at Valiant TMS. “The proven cycle time-reduction of 17% in comparison with manual programming is breathtaking – and will be a game-changer in automation.”

To begin, only a simulation file or digital twin of the cell that needs to be improved is necessary. Undertaking the entire optimization process is possible without causing any delays in a customer’s current production. Once the analysis is complete, validation of the results is next. After that, the newly optimized plan is transferred to the factory floor and put into use without delay.

“Manufacturers are always looking for ways to improve their production processes, but few have the time or resources to spend on such a lengthy, involved task,” said Peter Howard, CEO of Realtime Robotics. “We’re thrilled that our optimization solution has struck a chord with so many, automating the task of generating and testing potential layouts and paths to quickly present them with the optimized solution. They can reap the benefits without wasting hours of their team’s time.”

“I am impressed by the results provided by Realtime Robotics. It seems to be the best software among all on the market. Everything indicates that after some improvements it will be able to eliminate manual work during robot path creation,” said Pawel Kukowa, Simulation Engineer at Valiant TMS.