ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Festo’s New Pneumatics Makes Technological Leap

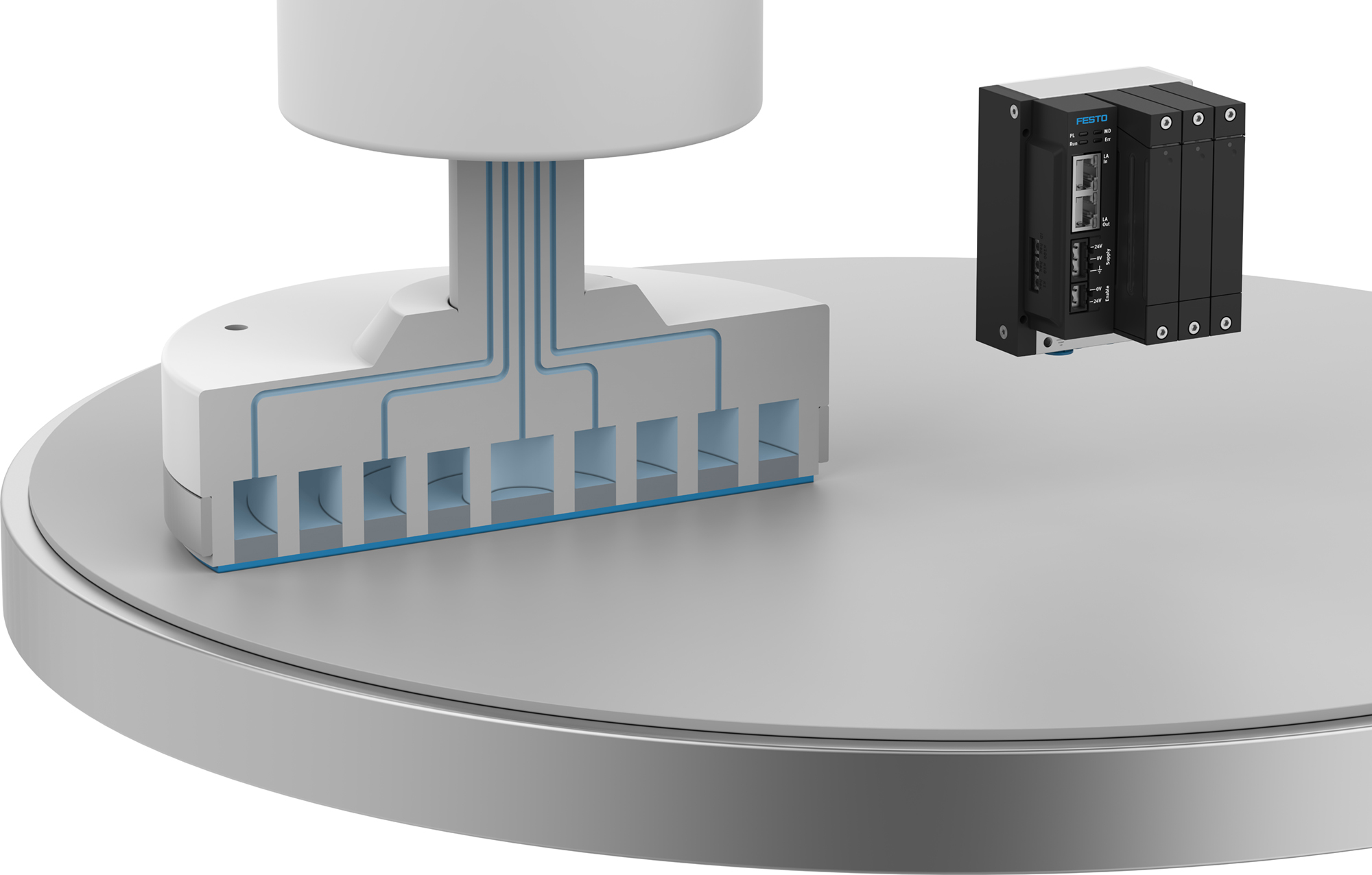

Controlled Pneumatics is Festo’s revolutionary compressed air technology that is opening up new perspectives for pneumatics. Thanks to this technology, the pressure control of the compact proportional valve terminal VTEP is extremely sensitive, down to less than 1mbar. Thus, this is perfect for wafer polishing or patch clamping. In addition, Controlled Pneumatics uses high-precision piezo valves to reduce compressed air consumption by up to 50%.

VTEP, the first proportional valve terminal on the market, offers high precision, fast response times, and dynamic control. Hence, this speeds up production. Moreover, it ensures that manufactured products are of a higher quality. This is how Festo makes machines and systems faster and more precise.

Furthermore, it also helps the electronics and semiconductor industries, textile manufacturing, battery production and life sciences, for example, to gain decisive competitive advantages.

Pressure or vacuum?

At less than 120mm wide, VTEP is the most compact proportional valve terminal on the market for pressure control with 10 working channels. Thus, there are three versions, 2-, 3- and 5-way, which can all be easily integrated for multi-channel applications. Pressure and vacuum can be combined in the control range of 6bar.

The directly controlled VTEP uses piezo technology, which, together with the appropriate control technology, makes the pneumatics extremely precise, fast, and economical. This offers additional benefits: the valves are quiet, free of wear, have no particle abrasion, and don’t generate any heat. The valve terminal is also free of copper, nickel, and zinc, making it very suitable for battery production and other industrial segments in which these materials are disruptive.

Wafers, batteries, and more

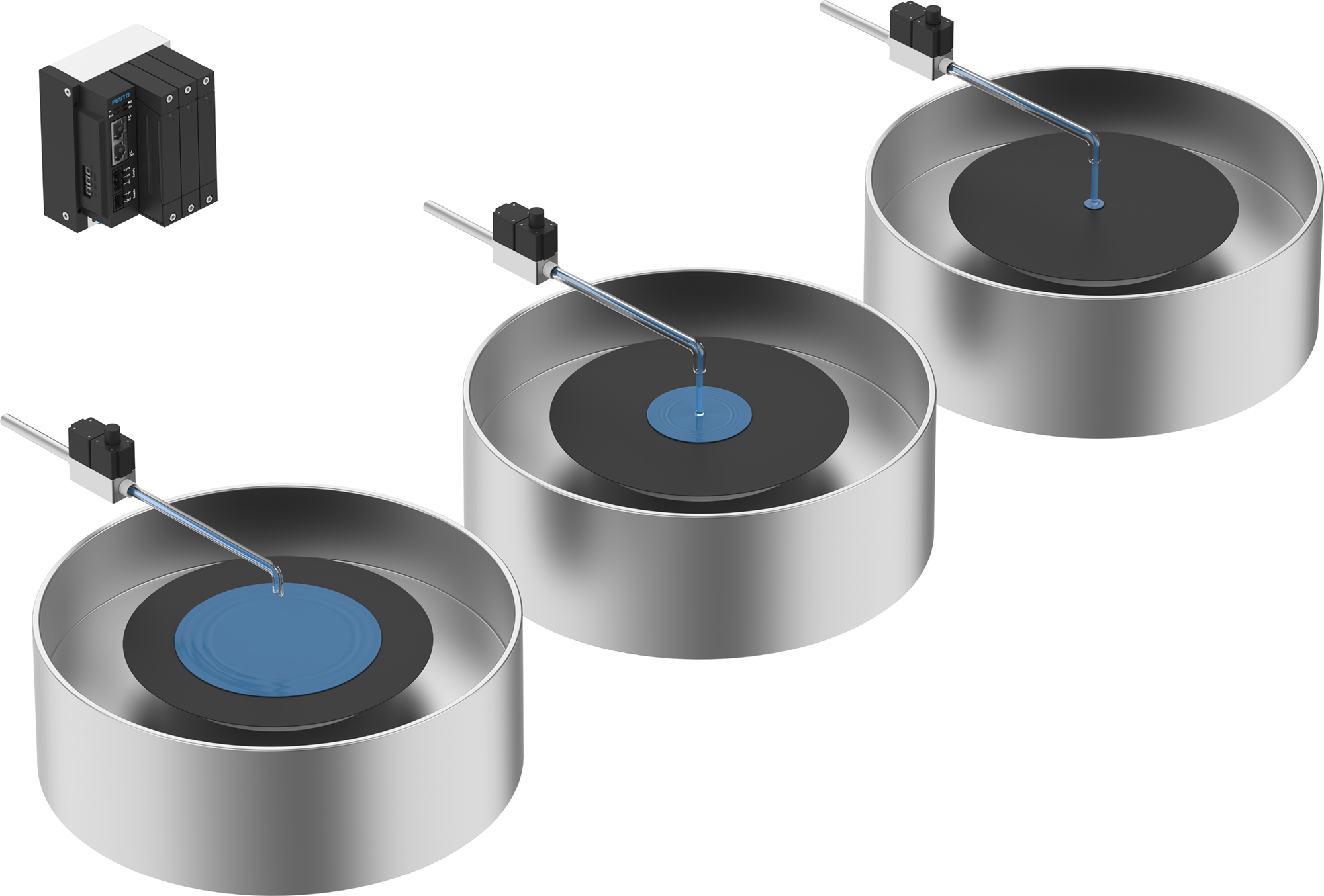

During wafer production, the variable contact pressure of the individual polishing chambers on the polishing unit is controlled extremely precisely by the VTEP using Controlled Pneumatics. The even pressure guarantees excellent results across the entire processing surface, even when polishing delicate wafers. Valve terminals type VTEP can also suit as pilot valves for media valves. For example, in photolithography, a light-resistant layer has to be precisely applied to wafers. A VTEP-controlled suck-back function ensures that no excess paint escapes.

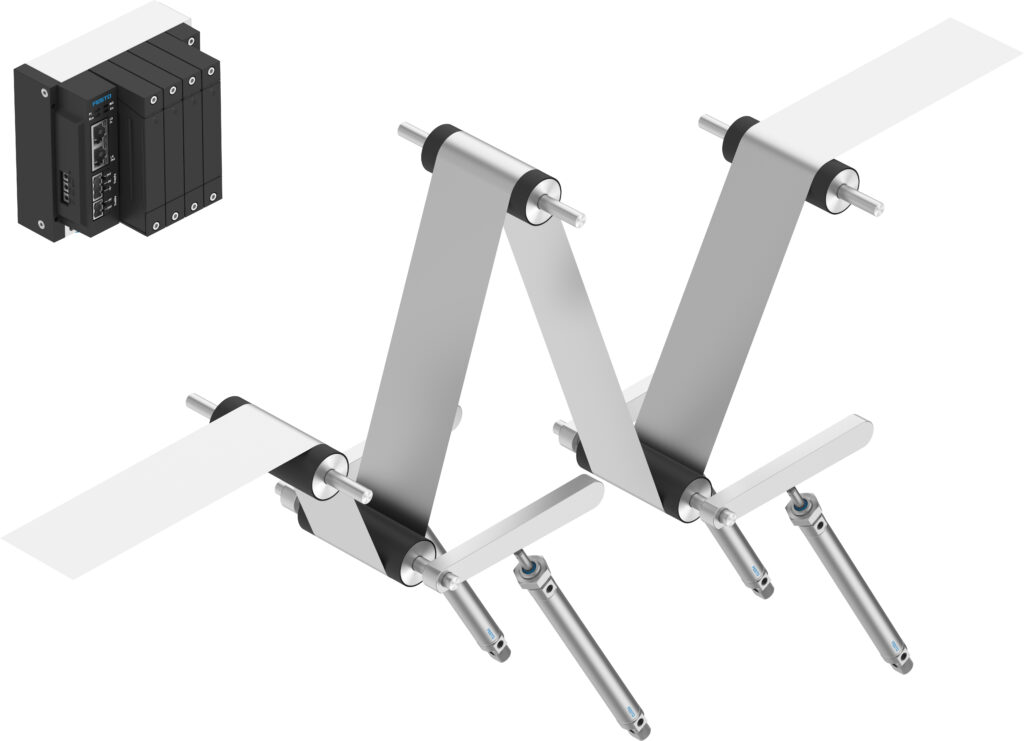

Moreover, the proportional valve terminal VTEP is also suitable for many applications in web control, such as the production of battery foils. VTEP communicates virtually in real time, and the valves react at lightning speed. Perfect timing guarantees significantly improved process reliability in the event of unexpected forces.

Festo is a global player and an independent family-owned company with headquarters in Esslingen am Neckar, Germany. Festo has set standards in industrial automation technology and technical education ever since its establishment, thereby making a contribution to sustainable development of the environment, the economy and society.

Propels Digital Factory

Meanwhile, the company supplies pneumatic and electrical automation technology to 300,000 customers of factory and process automation in over 35 industries.

Digitalization, AI and the LifeTech sector with medical technology and laboratory automation are becoming increasingly important. Thus, the products and services are available in 176 countries. With about 20,800 employees in over 250 branch offices in around 60 countries worldwide, Festo achieved a turnover of around €3.81 billion in 2022. Each year around 7% of this turnover is invested in research and development. In this learning company, 1.5 % of turnover is invested in basic and further training. Festo Didactic SE is a leading provider of technical education and training and offers its customers worldwide comprehensive digital and physical learning solutions in the industrial environment.