ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

FLOW Core 2.1 Enables Seamless Robot Installation

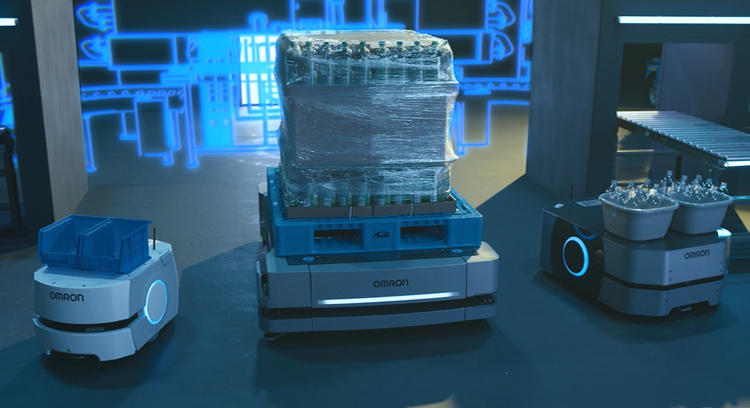

OMRON Corporation makes available Fleet Operations Workspace (FLOW) Core 2.1 software. The fleet management software eases introduction of mobile robots through simulation functions, integrated control of multiple robot types, and continuous improvement of running efficiency through running data analysis.

Advancing automation at manufacturing sites is increasingly needed. Its implementation can avoid the worsening manpower shortage and dense and close infection control. With this as backdrop, Omron enables easier and more efficient automation of the transfer process.

Automation, Fleet Management Issues

In recent years, mobile robots have been introduced to efficiently and safely automate the conveyance process. They address the increasingly serious labor shortage at manufacturing sites and free workers from heavy labor. The use of robots with different payloads and sizes is needed for transport processes, from material transport to processing and product shipment. However, human resources with mobile robot know-how are limited. This makes it difficult to verify the effectiveness of the system and design the line before introducing it.

Fleet management software is also needed for the integration of various types of mobile robots. In addition, the data collection required to optimize the relationship between each robot and each process takes a long time. Visualizing the running data on the manufacturing floor where production lots, processes, equipment, and people change frequently, is also a challenge.

Optimal Control of Multiple Mobile Robots

OMRON’s FLOW Core 2.1 software clarifies installation efficiency and issues before the actual installation of mobile robots through a fleet simulation function, enabling quick start-up. It also allows integrated control of multiple types of mobile robots with different payloads. This function eliminates the complexity of building a system for each type. Collection and visualization of travel data, and identification of bottlenecks are easy even after system installation. Thus, visualization of the gap between the effects of the system and those targeted at the time of installation, and improvement of travel efficiency are possible.

These processes shorten the adjustment and verification period of the mobile robot. The user immediately experiences the effects of transport automation, supporting the shift to smart factories in the manufacturing industry. Existing mobile robots can use these functions by updating the existing software to FLOW Core 2.1.

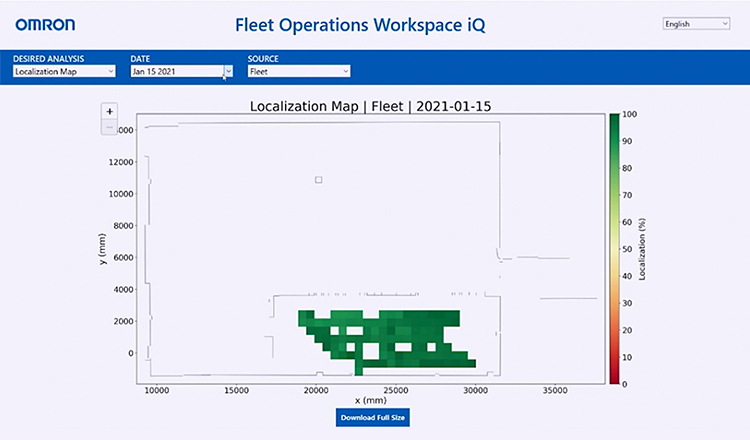

Travel Data Visualization, Analysis Functions

FLOW iQ visualizes information such as heat maps (where autonomous transfer robots are stagnating), path maps (where automated transfer robots are traveling), and robot usage rates (activity analysis) based on travel results. FLOW iQ makes it easy to troubleshoot complex fleets and supports continuous improvement.

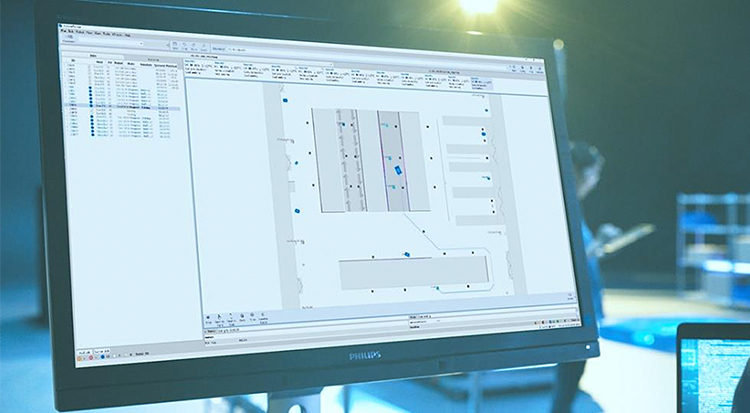

Fleet Simulation Function

FLOW iQ simulates the workflow and travel volume of a fleet of autonomous transport robots in digital space without actually deploying the robots. It has the ability to control multiple mobile robots as a swarm. Also, it can identify potential bottlenecks, shorten implementation time and optimize workflows.

Integrated Fleet Control Function

Customers can easily build fleets that combine multiple sizes and payloads, thus improving manufacturing throughput through integrated control.

OMRON is driving innovations on the production floor under the banner of “innovative-Automation,” concept, which consists of the three i’s, namely, “integrated (evolution in control),” “intelligent (intelligence developed through ICT),” and “interactive (new harmonization between humans and machines).”