ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

MinebeaMitsumi Goes Full Force in Production Automation

MinebeaMitsumi Inc. will launch a full-scale project to automate production. Specifically, the company implemented automation for approximately 6,000 workers, in the present fiscal year ending March 31, 2024. Also, it will work to unify systems and tools among recently acquired companies to create a global standard.

The challenges facing the manufacturing industry include acquiring manpower for manufacturing sites; rising wages worldwide; passing on manufacturing technology to the next generation; and stabilizing and improving quality. Recently, Minebea Mitsumi’s group has also been facing rising wages and difficulties in hiring people in many countries.

Addressing Industry Challenges

In this light, the company is working to classify, categorize, and automate processes throughout the group. Specifically, it is automating processes for approximately 6,000 workers in fiscal year ending March 2024 and a cumulative total of approximately 13,000 workers by fiscal year ending March 2026.

Additionally, the company will build a manufacturing system that makes full use of artificial intelligence (AI) and digital transformation (DX). Primarily, the company group, which has been pursuing mergers and acquisitions, has been dealing with different manufacturing philosophies of respectively acquired companies. Therefore, MinebeaMitsumi has decided to unify its improvement methods and IT tools to establish a common standard among these companies. Therefore, it will thoroughly eliminate waste at the manufacturing site.

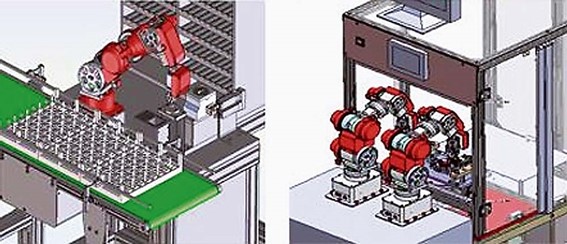

As part of its automation efforts, the company has created a robot floor in the Tokyo X Tech Garden, where its Tokyo Headquarters is located. Specifically, it aims to conduct research and trial production of robots to be used in promoting process automation at mass-production plants around the world. They are conducting various trials and examining how they can be used on the production line.

-15 March 2024 –

This is an English translation of a Japanese originally article published in Dempa Shimbun Daily.