ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Resonac Moves to Recycle Wastes from IC Production

Resonac Corporation has started to consider recycling plastic waste emitted from the semiconductor manufacturing process and consider reusing them.

Particularly, Resonac plans to apply the company’s plastic chemical recycling technology*1 to that plastic waste and convert it into hydrogen and carbon dioxide. Resonac implemented the first verification test in late January of this year and confirmed that there is nothing wrong with the gasification process.

Plastic waste used in the verification test of this time came from the production process of photosensitive film operated in Yamazaki Plant. At the same time, from that of die bonding film operated in Goi Plant.

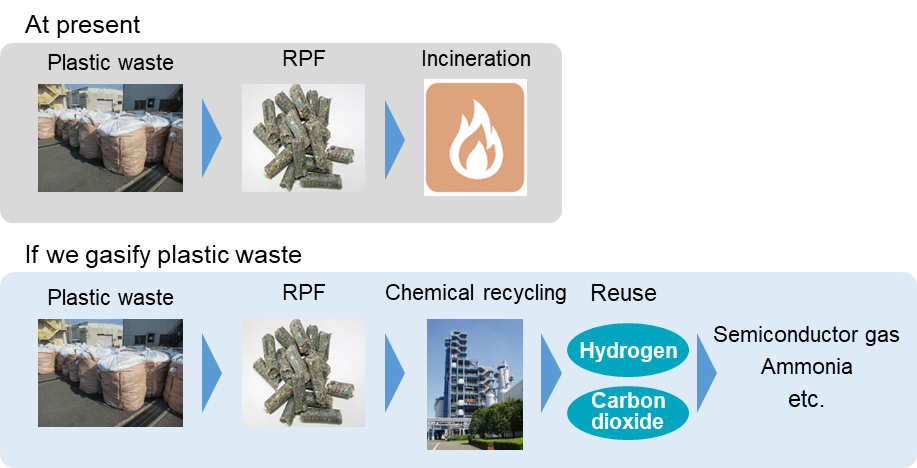

In the verification test, Resonac processed plastic waste and converted it into RPF*2. Thereafter, they decomposed the RPF into molecules of hydrogen and carbon dioxide at the plant for the Kawasaki Plastic Chemical Recycling Business (KPR*3).

In KPR, the company first utilized the extracted hydrogen as a material to produce ammonia. Next, they used this produce as material to produce high-purity gases for semiconductor manufacturing, synthetic fibers, adhesives, and nitrogen fertilizers. Finally, instead of emitting the extracted carbon dioxide into the atmosphere, they used it as material to produce dry ice and carbonated drinks.

Sustainable Manufacturing

Under the existing circumstances, plastic waste emitted from the semiconductor manufacturing process becomes RPF and incinerated. However, as confirmed in the verification test, gasification of plastic waste can reduce CO2 emission.

Recently, progress in AI, mobile devices, and autonomous driving has increased the demand for semiconductors. Accordingly, the burden on the environment brought by the production process of semiconductors including the amount of CO2 emission is increasing.

Therefore, the social need for environmental consciousness of the semiconductor supply chain as a whole is increasing year by year. For that reason, Resonac has been striving to reduce environmental burden and CO2 emission by taking into consideration the entire lifecycle of production.

Recycling of plastic waste emitted from the semiconductor manufacturing process is part of this endeavor. Thus, the company is promoting this effort as a co-creation beyond barriers between industries.

Resonac will increase the number of plants involved in the verification test. Moreover, make thorough investigation into effects and feasibility of recycling of plastic waste emitted from semiconductor manufacturing process.

Notes:

*1: Plastic chemical recycling plant decomposes used plastics into molecules of hydrogen and carbon dioxide. Particularly, these extracts are suitable for production of ammonia and dry ice.

*2: RPF is an abbreviation of “Refuse derived paper and plastics densified Fuel.” RPF comes from used plastics and other industrial wastes which are rather difficult to recycle as materials.

*3: KPR went into operation in 2003 and is the only plastic gasification and chemical recycling plant in the world. Essentially, it has been in stable operation for 20 years. On the other hand, KPR gasifies and chemically recycles 70,000 tons of used plastics per year, which accounts for about 22% of total chemically recycled plastics in Japan.

At high temperatures, KPR decomposes used plastics into molecules of hydrogen and CO2 (Gasification and chemical recycling of used plastics). Hydrogen extracted from used plastics suits as material to produce other chemicals in neighboring plants.

In addition, the company makes use of CO2 extracted from used plastics for recycling and not emitted into the air. Thus, reusing them as a material to produce dry ice, carbonated drinks, and medical CO2.

-9 April 2024-