ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

TSMC's New Site to Bring 3DFabric Solution to Fruition

Taiwan Semiconductor Manufacturing Company, Limited (TSMC) has highlighted its semiconductor integrated manufacturing concept that will unleash innovation in the semiconductor supply chain. At a virtual Semicon Taiwan forum, the company detailed its plans in making ICs more powerful with the adoption of an advanced packaging technology in a new manufacturing site.

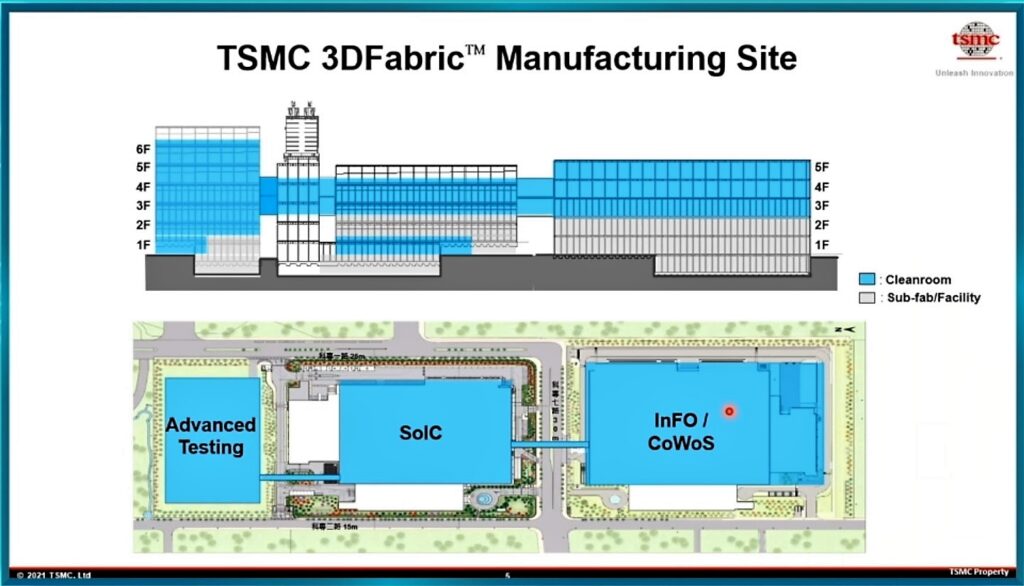

Dr. Marvin Liao, Vice President, Operations/Advanced Packaging Technology and Service said a new TSMC fully automated manufacturing site will employ 3DFabric technology and will have advanced packaging and testing bases. The 3DFabric manufacturing site will have three connected plants featuring 3DFabric’s complete system integration portfolio.

“Our purpose of providing this manufacturing capabilities is we want to integrate these capabilities to unleash customers’ innovations. TSMC will create the more advanced silicon and make it ready for the 3D stacking and advanced packaging,” said Liao in the Smart Manufacturing Forum.

Complete System Integration

One of the plants in the planned 3DFabric manufacturing site is the System on Integrated Chip (SoIC). This will process 3D technology and will stack and link several types of chips such as active and passive chips, into a new integrated SoC system for better form factor and performance.

Another facility that will rise in the planned manufacturing site is the combined Integrated Fan-Out (InFO) wafer-level packaging platform and CoWoS, which will primarily process 2.5D advanced packaging capabilities. InFO features high density redistribution layer (RDL) and Through InFo Via (TIV). This will provide high-density interconnect and performance for various applications such as mobile and high-performance computing. The InFO platform offers various package schemes in 2D, and 3D optimized for specific applications.

“The SoIC facility will start equipment installation from this year while the InFO and CoWOS and advanced testing will be ready in next year,” said Liao.

Liao said the company is on schedule in developing 3nm using advanced silicon technology and in the future, in 2nm chips. He said they are hopeful to bring these advanced silicon technologies furthermore to its 3DFabric solution in 3nm in 2023 and 2024.

Intelligent Automation

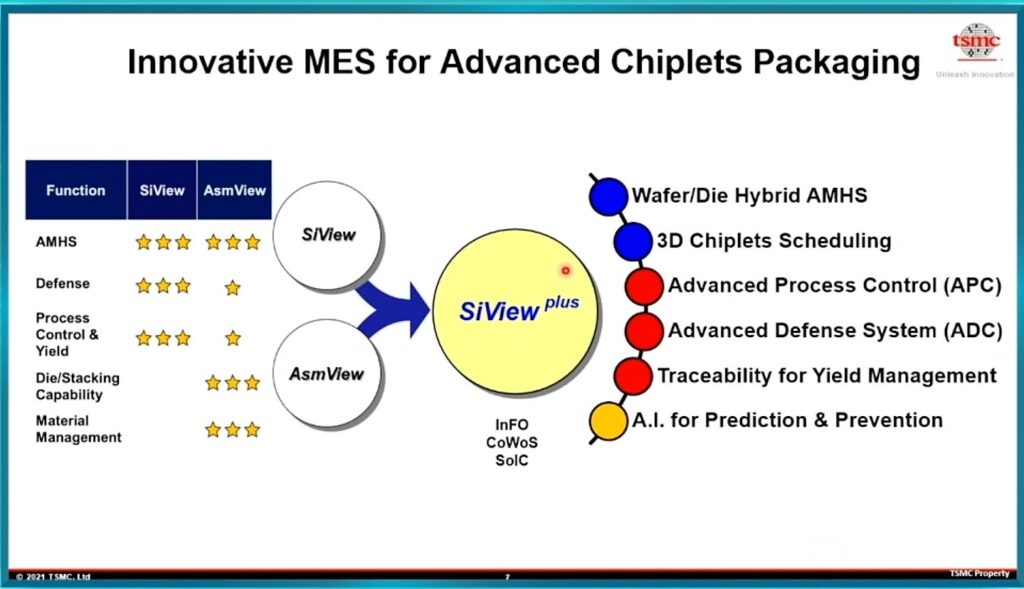

Liao said TSMC will employ several intelligent fab automation systems with its new 3DFabric manufacturing site. This will include innovative Manufacturing Execution System (MES), Advanced Process Control (APC), and Automated Material Handling System (AMHS).

For the MES for advanced chiplet packaging, TSMC will combine its SIView and ASMView technologies to create SiView Plus to provide instant die-level information for instant die-level information, real-time dispatching, and comprehensive defect interception and classification. It also works on automated yield prediction and optimization and artificial intelligence (AI) for prediction and prevention.

“In order to make the full automation crust here, from die stacking all the way to advanced packaging, we are going to have 5-in-1 Automatic Material Handling System (AMHS) covering from the tray, magazine, and in the middle a frame, as well as silicon and glass handling. We are going to have five different materials handling in this fully automatic system from die stacking to advanced packaging,” said Liao.

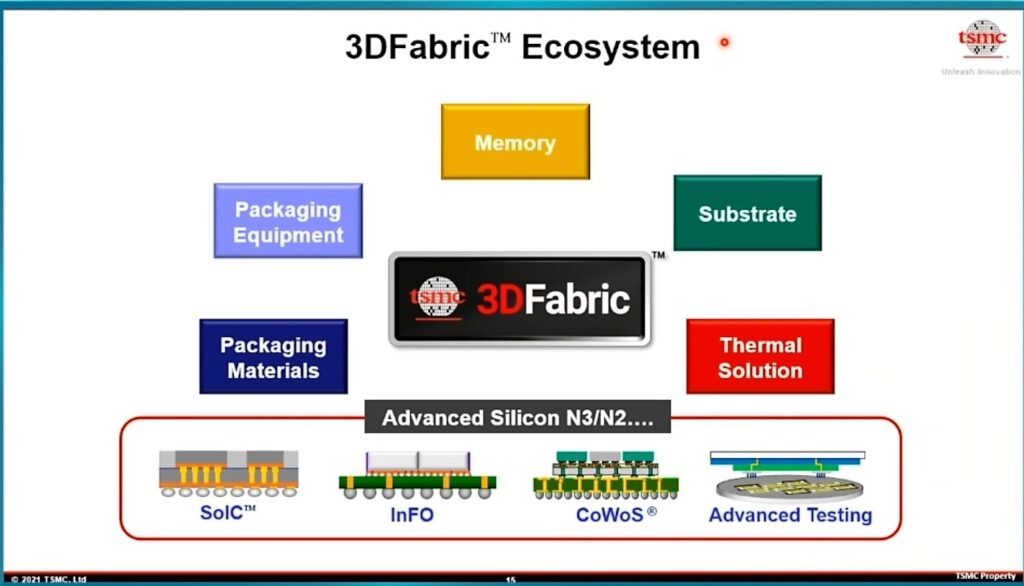

Liao said TSMC will be able to strengthen the ecosystem for its 3DFabric solution, which would include manufacturers of memory, substrate, thermal solution, packaging materials, and packaging equipment.

The combined experiences of TSMC in 300m fab and 3DFabric fab will create technology, cycle time, and quality values to the company. This in turn will give its customers improved time to market, time to volume, and time to yield. “Altogether, we are going to have very close integration. Integrated manufacturing capabilities between the 300mm advanced silicon fab and the 3D advanced packaging fab. By putting these two manufacturing capabilities together, we are ready to provide the value for our customers,” said Liao.