ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Ultimaker Offers New Standard in Industrial-Grade 3D Printing

UltiMaker has announced the release of the UltiMaker Factor 4 industrial-grade 3D printer, designed to take manufacturing to new levels of efficiency and reliability. Primarily, Factor 4 is an end-to-end 3D printing solution for light industrial applications.

Mainly, the UltiMaker Factor 4 3D printer is a new end-to-end 3D printing solution for light industrial applications. It offers support for engineering materials, direct drive dual extrusion, onboard print process reporting, and temperature-controlled build volume. Additionally, Factor 4 delivers high levels of predictability and minimal variance. The printer is designed to take manufacturing to new levels of efficiency and reliability. It is built on over a decade of dedication to openness and accessibility. Thus, it can support one of the widest material portfolios for a variety of applications. These include end-use parts, functional prototyping, manufacturing tools, and small batch manufacturing of auxiliary components and spares.

Moreover, Factor 4 offers a temperature-controlled build volume of 330×240×300mm. Also, it features uniform bed heating, ensuring consistent performance across the entire build plate. Designed for manufacturing and industrial sectors, it launches with a new high-temperature print core. Specifically, it allows engineers to print up to 340°C. This enables a broader range of high-performance, temperature-resistant, and durable materials, such as the new UltiMaker PPS CF, a high-temperature composite material. The machine efficiently uses the heated bed and actively controlled chamber airflow to manage the build volume temperature up to 70°C. Thus, it ensures optimal material-specific processing conditions and consistent part quality wherever the 3D printer is located.

Also, Factor 4 is thoroughly tested to achieve over 95% print completion success and dimensional accuracy within ± 0.2mm or ± 0.2% of the feature nominal length.1 Thus, it is fit to deliver consistent results across multiple machines—optimal for producing validated parts for distributed manufacturing. The printer’s versatility, reliability, and ease of use make it ideal for industries looking to optimize their production workflows and accelerate development. The latest print profiles for Factor 4, available on Cura 5.7.1, enable engineering materials, such as PET-CF and Nylon, to be printed with productivity levels similar to Tough PLA and PETG, effectively doubling print speed when compared to the UltiMaker S series.2

“Our commitment to customers goes beyond providing just a 3D printer; we offer a full 3D printing ecosystem, including hardware, software, materials, training, and support,” said Michiel Alting von Geusau, CEO at UltiMaker. “With our comprehensive support, we help customers navigate through the complexities of 3D printing and identify opportunities. There is untapped potential in the light industrial market. We believe that Factor 4 will enable customers to further explore the application possibilities in this space. With its efficiency and versatility, Factor 4 promises a quick return on investment. This allows businesses to capitalize on the benefits of 3D printing.”

Key features of UltiMaker Factor 4

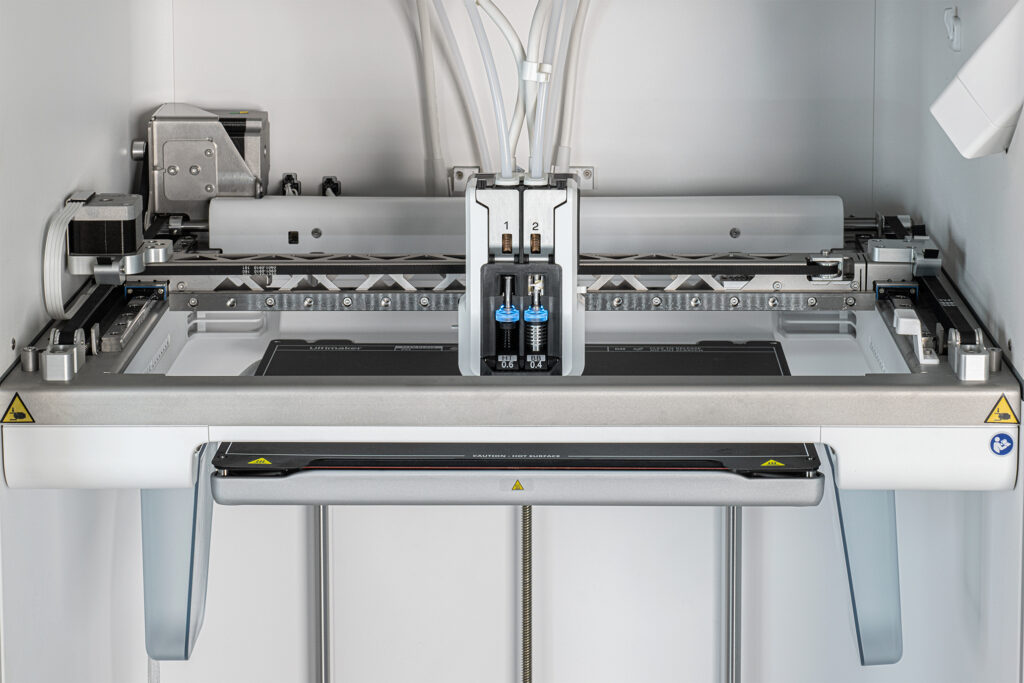

Industrial-Grade Performance

Constructed from robust steel, aluminum, and glass, Factor 4 is built for the factory floor. The printer features a triple-insulated build volume, closed loop and direct-drive dual extrusion. Also, it features automatic inductive bed leveling, and a PEI-coated flexible build plate, ensuring consistent production output, even on complex and challenging designs. These features combined with the all-new H-bridge gantry and a rigid all metal frame allow for high-speed movement and accuracy.

Automatic Material Handling and Storage

Additionally, the integrated, low moisture material handling system allows engineers to reliably manage their print jobs. The material station is climate-controlled, with humidity levels kept below 15%. Also, it holds up to six spools of filaments in their prime condition. It features an automatic material change capability, which seamlessly switches between spools, eliminating downtime and ensuring uninterrupted printing, for those printing a single part that may require several days or multiple spools.

Expanded Material Diversity

The new printer expands the range of high-performance, industrial-grade materials. Thus, it enables production of structural integrity-verified parts, from flexible materials to high-temperature composites, such as the UltiMaker PPS CF. UltiMaker PPS CF is a semi-crystalline thermoplastic material, reinforced with carbon fiber. The material has a temperature resistance greater than 230°C and is flame retardant. It provides a high-performing alternative to steel or aluminum for less-demanding parts, enabling users to unlock new industrial applications.

Seamless Workflow Integration

The UltiMaker Cura 5.7.1 release has new print profiles for Factor 4, customized and fine-tuned for optimal print quality and performance. With automatic recognition of UltiMaker materials and print cores in Cura, Factor 4 offers a smooth 3D printing experience. The printer is also compatible with major CAD software.

Powerful Onboard Print Process Reporting

The machine has a 7″ capacitive touch screen and a suite of sensors in the print head, build volume, and automated material loading system. Specifically, it monitors real-time data on printer and material performance and delivers in-depth reporting after every print job, ensuring easy part validation and quality control.

Modular System for Simplified Maintenance

The printer offers a modular design that allows for easy repairs and maintenance, minimizing downtime and maximizing productivity.

“With Factor 4, we are introducing a reliable industrial-grade solution that provides a solid long-term investment,” said Andrea Gasperini, Product Manager, B2B Solutions, at UltiMaker. “Our focus remains on releasing products that can meet current needs and adapt and improve over time. Factor 4 delivers the reliability that UltiMaker products are known for, while also being able to seamlessly integrate alongside other industrial machinery and production processes.”

Materials available for Factor 4 include UltiMaker PPS CF and other UltiMaker-branded materials, such as PLA, Tough PLA, nylon, PETG, PET CF, and PVA, as well as validated materials from BASF Forward AM, Kimya, Polymaker, LEHVOSS, Jabil, and more suppliers. Factor 4 is compatible with materials on the UltiMaker Marketplace, with 250 pre-tuned print profiles. Factor 4 supports 2.85mm filament.

The printer is equipped with an integrated HEPA filter and a large red STOP button. Thus, it ensures safer 3D printing anywhere in factory or office environments. Factor 4 is expected to begin shipping in May 2024.

Factor 4 is on display at HANNOVER MESSE from April 22-26, 2024, in Hannover, Germany, in Hall 17 booth D35. Also, UltiMaker will exhibit and showcase Factor 4 and other professional 3D printing solutions at TCT Asia in Shanghai, from May 7-9, 2024, in booth 8F90 at National Exhibition and Convention Center Hall 8.1.

-23 April 2024-