ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

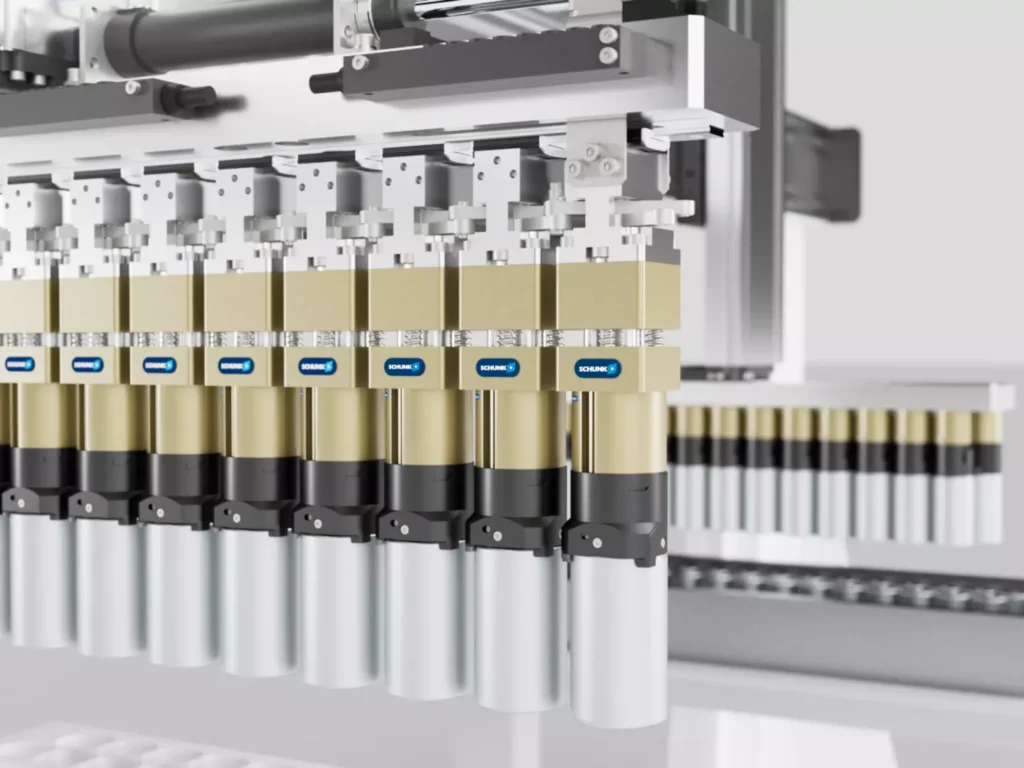

SCHUNK Takes on e-Mobility with New Round Cell Gripper

As a partner of the automotive industry, SCHUNK has the right handling concept for every drive in its portfolio. For the heart of e-mobility, the battery, SCHUNK offers the RCG round cell gripper as the first standard product from the e-mobility range. Specifically, the pneumatically controlled magnetic system enables handling of individual battery cells. Also, if they are used in multi-gripping units, precise and process-reliable equipping of complete cell clusters without interfering contours.

The greatest cost driver in an electric car is the battery. Recently, car manufacturers worldwide have been exploring ways to develop and produce batteries that are not only sustainable, but also cost-efficient and which have enough power for long ranges. In addition to prismatic and pouch cells, major manufacturers are increasingly relying on round cells with a diameter of 46mm.

In relation, the new tool from SCHUNK specifically suits handling this type of cell: the RCG round cell gripper. It is freely scalable; this way, individual battery cells can be handled and automatically arranged in rows. Also, precise and fast loading of entire battery clusters is possible in an uncomplicated and safe manner.

Safety Thanks to Integrated Gripping Force Maintenance

Specifically, the RCG round cell grippers have a pneumatically controlled magnetic system for picking and placing battery cells magnetically. The permanent magnet inside the individual gripper ensures secure gripping force maintenance during the complete process. Even in case of a possible energy loss during an emergency stop, the battery is held by the gripper. The high holding force of the magnets >70 N is suitable for any battery length and enables high acceleration rates of the robot in use.

Additionally, the RCG’s sensory workpiece and status detection also contribute to process reliability. They recognize whether a battery is present, but also enable piston stroke monitoring. Also, the SCHUNK designers have adapted the RCG precisely to battery cells with 46mm. Accordingly, it achieves maximum possible power density of the battery cells within the battery cluster and without interfering contours. SCHUNK offers the gripper in three versions: without centering, with 2-fold centering or with 4-fold centering for tolerance compensation when picking up the battery cells.

Perfect for Series

It is possible to combine the system with other SCHUNK components for use in a production line. Particularly, they are suitable sensors, compensation and cell spacing units, as well as linear direct axes enable precise, dynamic, and safe processes in series production of battery packs.

-23 April 2024-