ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Research Center To Offer Siemens' Best High Tech Tools

The Fraunhofer Institute for Systems and Innovation Research [Fraunhofer ISI] said battery production capacity in Europe will quadruple by 2025. Specifically, from 124GWh in 2022 to over 500GWh.

Moreover, by 2030, this figure will likely increase tenfold to up to 1.5TWh.

Given these projections, the Westphalian city of Munster will soon unveil the largest German and Europe-wide unique competence center. To illustrate, its role is to develop and test the production of battery cells. This includes electrically powered vehicles.

What’s more, the center has already achieved a major milestone. The commissioning of innovative European machine technology for the “FFB PreFab.”

This is an important step toward establishing the “FFB Fab,” enabling industry-oriented production research on plant technology. Moreover, on an industrial scale in Münster.

As a battery cell factory focused on R&D, Fraunhofer FFB will make a key contribution to advancing the production of battery cells “Made in Germany” or “Made in Europe”. Thus, positioning them at the forefront of strong international competition.

The Federal Ministry of Education and Research [BMBF] and the State of North Rhine-Westphalia are funding the creation of a facility for researching battery production with about €680 million. This guarantees production in Germany can provide new battery technologies more efficiently, cost-effectively, and at the highest quality in the future.

Research production provides an infrastructure. Specifically, for all companies and research institutions to test, implement, and optimize the near-series production of new batteries.

How Siemens Helps Fraunhofer FFB

The Fraunhofer-Gesellschaft is implementing this project step by step with several partner companies. In fact, one of these partners is Siemens AG. Specifically, Siemens provides Fraunhofer FFB with software and hardware solutions based on the open Siemens Xcelerator platform.

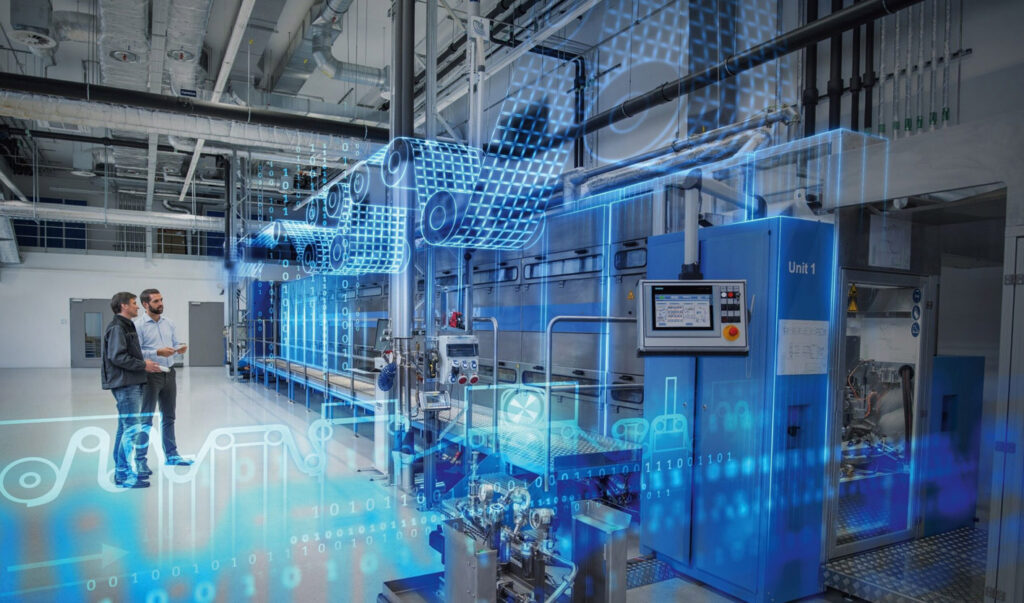

With their interoperable systems, the Digital Industries and Smart Infrastructure Business Units contribute to the digitalization, automation, control, and monitoring of the machines, processes, and buildings. The tools are digitally mapping out the real production and environmental conditions along the entire value chain. Specifically, connecting operational technology to information technology. Sensors in the building and throughout the production environment will provide all relevant infrastructure data in real time.

Meanwhile, because of Manufacturing Execution System [MES] and the IIoT platform, Fraunhofer FFB can plan, control, optimize, and flexibly scale its production processes. The Desigo CC building management platform will determine the optimal production environment with data-based and demand-oriented processes, even in clean rooms and drying operations.

The collected data will be of central importance for Fraunhofer FFB. Particularly, in fulfilling its mission of researching the production of battery cells using a digital twin of the factory.

The digital twin reflects the entire factory, from the technical building equipment to all production processes. This guarantees production under near-series and difficult conditions, e.g. clean room production, for a variety of industrial partners.

“Automation and digitalization are the keys to continuing to be competitive in industrial production in Germany in the future. With its construction of a new research factory for battery cells in Münster, the Fraunhofer-Gesellschaft will play an important pioneering role for the German electromobility supply industry. Siemens is contributing its industry-specific expertise in automation and digitalization,” says Thorsten Selle, Head of the Siemens branch in Münster.

6 May 2024