ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Equipment Makers Flex More Muscle As Markets Recover

The onset of the novel coronavirus (COVID-19) pandemic has suppressed capital investments in the manufacturing industry. However, as global economies start to recover and so as investments, linear motion guides manufacturers have revitalized the market by introducing new products.

Promotes Labor Savings

THK Co., Ltd. has been working to promote and expand further the OMNIedge internet of things (IoT) service for the manufacturing industry. At the same time, the company has been introducing new products of basic machine element components, such as linear motion guides, aiming to stimulate the market.

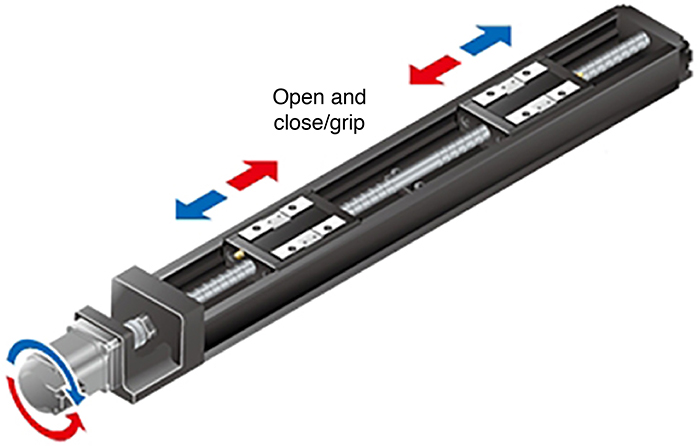

THK has started receiving orders for the KR-RL LM guide actuator that adopts right and left screw for the ball screw shaft of the drive section. The adoption of the screw that moves symmetrically enables open-and-close operations and gripping using a single motor control. This contributes to labor savings. As they are capable of right and left symmetrical movement with a single axis, the KR-RL allows the replacement of multi-axes component products with simpler single-axis modular products. It best suits the end effector of a robot arm that makes complex movements.

Sees Co-Creation With Customers

For its business approach, Nippon Thompson Co., Ltd. pursues “deepening, taking on challenges, and innovative changes.” It has also been endeavoring to expand its business by enhancing co-creation of values together with customers.

Shigeki Miyachi, President, Nippon Thompson Co., Ltd., said “Our company, as part of its corporate philosophy, aims to become a technology development company that contributes to the society. Businesses that are built on technologies support our company’s growth.” Miyachi noted the company’s technology-focused management.

The company has been expanding its product lineup of linear motion guides filled with liquid crystal lubricant, developed for the first time through industry-academia collaboration. They call this as the “Liquid Crystal Lubricant Series”. Liquid crystal lubricants are completely different from greases composed of base oils and thickeners. These are composed only of liquid crystal compounds, and their aggregates form a lubricating state, which exhibits novel lubrication performance.

As the liquid crystal lubricant series, Nippon Thompson has brought to the market Liquid Crystal Lubricant Linear Way linear motion guide, and the Linear Roller Way Super X Series, and a product that adopts the liquid crystal lubricant for cross roller bearings as well. The liquid crystal lubricant series meets increasing precision of manufacturing equipment for semiconductors that are becoming increasingly finer.

Nippon Thompson has been expanding high-precision positioning tables and other products that combine linear motion guide and electronics as mechatronics products. The company has added the SK…W rotary stage to its lineup of mechatronics products. They introduced this to the market in July. The SK…W adopts the drive method using a worm gear mechanism, and a cross roller bearings at the rotation guiding section, used as the table itself. The rotary stage achieves high rotation waggle accuracy, high rigidity, and low cross section.

Applies Unique Technology

NSK Ltd. set up in Oct. 2020 Electrical & Electrification (E&E) Division HQ in the Industrial Machinery Business Division HQ to strengthen ball bearings for various small motors in the industrial machinery field. With this, the company has put in place a system to flexibly perform design, development, manufacture, and marketing of ball bearings ranging from miniature ball bearings to those with an outside diameter of up to 60mm.

The company put on the market the Long-Life Series DH/DS linear guides in April. DH/DS linear guides achieve twice the running distance compared to the conventional series. NSK applies to its linear guides the TF Tough Technology, the company’s unique heat treatment technology. NSK’s Core Technology R&D Center has refined in the development of bearings for over many years. TF heat treatment controls the amount of retained austenite in steel to extend life of rolling elements.

精密工業第三期工事(正面右奥から真ん中) 完成予想図-150x150.jpg)