ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

HORIBA Boosts Chip Yield with New Laser Gas Analyzer

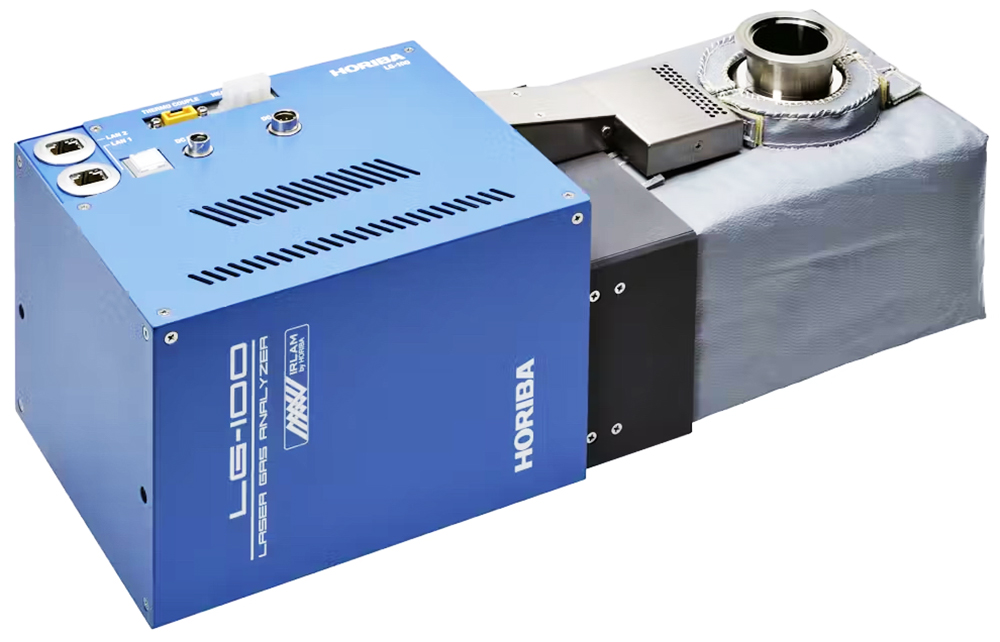

HORIBA STEC, Co., Ltd. has recently released the LG-100 Series laser gas analyzer, which featured its unique built-in IRLAM™ infrared gas analysis technology. This proprietary technology enables the product to support advanced manufacturing processes for semiconductors.

Features of LG-100

Particularly, this product can take real-time measurements of partial pressure*1 changes in the silicon tetrafluoride (SiF4) produced during the etching process used in semiconductor manufacturing. These changes enable manufacturers to determine whether the etching has reached a permissible depth (endpoint*2).

Also, LG-100 reduces the risk of under-etching*3 and over-etching*3. Therefore, it contributes to higher productivity and yield when manufacturing semiconductors.

In addition, the LG-100 comes equipped with IRLAM™*4, HORIBA’s unique infrared gas analysis technology developed in 2021. Specifically, it realizes highly sensitive and fast (0.1 sec.) measurements of trace gases at a ppb*5 level.

HORIBA STEC continues to broaden the multi-component gas analysis, improve response speed, and expand LG-100 functionality in other ways that contribute to the ever-evolving semiconductor manufacturing process.

Boosts Chip Manufacturing Productivity

Generally, the etching process to engrave a circuit on a board using various gases demands precision control and measurement of those gases with the evolution to three-dimensional structures and refinement of modern semiconductor devices. So, it has become even more important to stop the etching process at the optimal endpoint to increase yield. To address these types of etching needs, HORIBA STEC has developed LG-100 as a device that can measure partial gas pressure in real-time during the etching process.

Koji Imamura, head of the Development Division at HORIBA, explains, “More sophisticated sensing technologies are necessary for advanced logic semiconductors. The release of LG-100 contributes to greater productivity in manufacturing processes to produce these state-of-the-art semiconductors. Going forward, we will continue to respond to diverse customer needs by expanding products with built-in IRLAM technologies.”

Notes:

*1 Pressure of each gas in a mixture

*2 Endpoint for the depth to engrave a wafer when etching a circuit

*3 Too little or too much etching from the target depth

*4 IRLAM stands for Infrared Laser Absorption Modulation. IRLAM is a registered trademark or trademark of HORIBA, Ltd. in Japan and/or other countries.

*5 ppb stands for parts-per-billion. 1 ppb means 1 liter of gas has 1 billion specific gas components.

-10 June 2024-