ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Panasonic Connect Pursues Smart Factory in New Platform

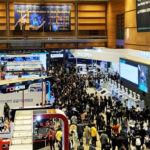

At JISSO PROTEC 2024, the displays at Panasonic Connect Co., Ltd.’s booth focus on realizing the “Autonomous Factory”.

Particularly, the company highlighted a new platform for mounting systems, as well as a device for parts supply automation. Specifically, this new product captured the interest of visitors.

The Autonomous Factory independently controls the 5Ms (Men, Methods, Machines, Materials, and Measurements). Specifically, they are the variable elements of a production site. The concept is to realize a factory that can respond immediately to changes in customer demand and supply. It also has to continuously evolve autonomously.

Towards an Autonomous Factory

The Panasonic Connect booth featured the NPM-G Series, a new platform for electronic component mounting systems that realize an autonomous factory.

Specifically, the modular mounter NPM-GH achieves both high mounting accuracy and high productivity. To achieve these features, the company equipped the mounter with a lighter mounting head, smaller vision camera, and faster axes. Meanwhile, the NPM-GP/L screen printer was displayed for reference, along with a mask changer with a smaller footprint.

Moreover, the Auto Setting Feeder (ASF) is a component supply automation product, which is available for orders beginning in June. Components for the mounting process are packaged in reels, and the reels are set in a cassette feeder. The ASF reduces this process time by approximately 50 percent compared with the company’s evaluation data.

The reeled parts of the new product which have been pre-processed with a dedicated jig. They are automatically set by inserting them through the insertion slot. Component positioning is also automated, enabling 9,200CPH with the company’s highest-ever mounting accuracy of ±10µm.

Also, splicing work is no longer necessary to connect the next reel to the last end of the reel to prevent parts from running out. The next reel is automatically filled when the next reel is set.

The ASF is currently available for tape widths from 8 to 104mm and will also be available for 4mm widths in the future. The system embodies a retrofit design that utilizes existing equipment.

Particularly, APC-5M software, which monitors 5M status in realtime and detects line changes, has been made compatible with all NPM Series models since April.

Akihiro Akiyama, Senior Vice President of Panasonic Connect, said, “With customers who have difficulty making initial investments, we want to work with them to evolve their current facilities. We will work together with our customers to make progress, and we will create a new form of co-creation with them.”

This is a translation of a Japanese article originally published in Dempa Shimbun Daily.

-04 July 2024-