ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Panasonic Makes Autonomous Factory a Reality

Panasonic Connect Co., Ltd. Process-Automation Business Division has introduced the NPM G Series, an integrated range of surface mounted technology (SMT) production systems.

The NPM G Series was designed to respond in real-time to customer supply and demand changes through continuous, autonomous updates. This feature helps to make the autonomous factory a reality. Overall, the mounting system offers flexibility and customizable options to address production needs and extend automation in manufacturing.

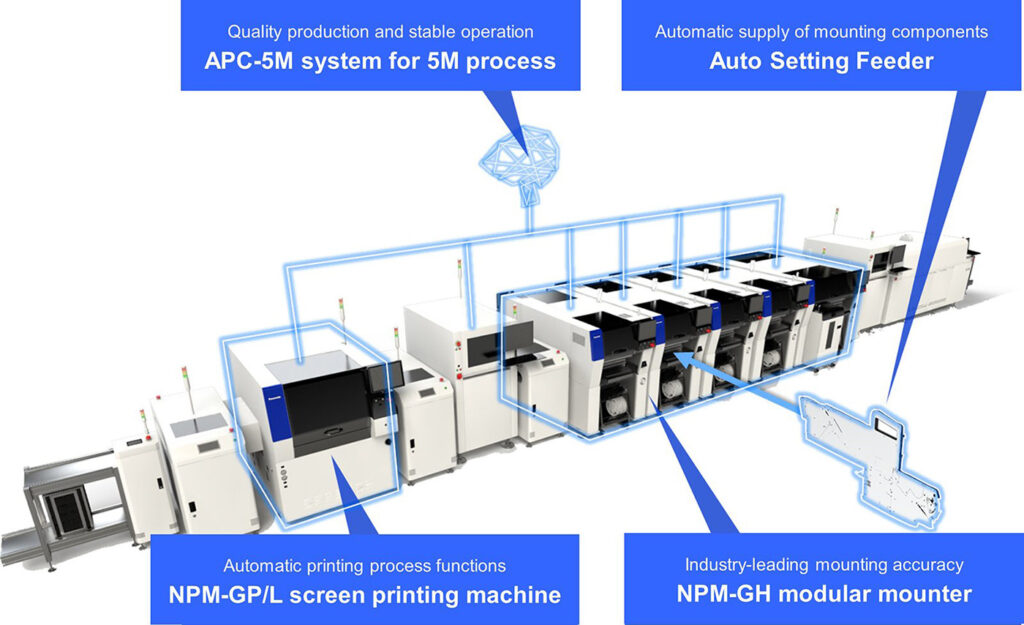

Many production sites still rely on their employee’s knowledge and manpower – the so called 5M (human, machine, material, method, measurement) method. The new Panasonic NPM G Series uses artificial intelligence (AI) and automated production to improve the process. Also, the use of the auto setting feeder (ASF), NPM-GP/L stencil printer, and NPM-GH pick-and-place machine enables customers to set-up individual, flexible, efficient, and economical production lines.

Automated Material Supply

The ASF delivers an automated material supply by smoothly inserting components into the production line. It is accomplished without the requirement for an operator to physically connect the old component reel with the new reel using splice tapes or clips. Moreover, it automatically peels off the cover tape for feeding surface-mounted components with a width of 4 to 104mm. Then, the loading unit automatically feeds the next tape and refills as required. Existing Panasonic machines from the NPM and NPM-X Series can also be adapted and equipped with the new ASF.

High-Precision Printing, Solder Performance

In addition, the NPM-GP/L stencil printer offers high-precision printing and solder performance combined with a high degree of integrated automation. Up to 10 masks can be stored and switched autonomously by a mask changer. An automatic solder supply and remove function, in combination with autonomous replacement of the underlay pin that supports the printed circuit board (PCB), enables efficient and high-speed production. The printer achieves a printing performance with a mechanical repeat accuracy of ±3.8μm and a cycle time of 12sec. This includes the cleaning process after each printing operation.

Increased Productivity, Accuracy

Further in the production line, the compact and lightweight placement head of the NPM-GH pick and place machine delivers high-level productivity (max. 41,000cph – total number of assembled chips per hour under optimal conditions). It features outstanding accuracy of ±15μm, as well as optional ultra-precise placement at ±10μm. Operability has been improved, thanks to simultaneous front and rear operations. Thus, the NPM-GH increases overall quality, output and ultimately boosts automation within the production line.

AI-driven Control Systems

The entire production process and machines are monitored through feed-forward and feed-back communication technology, called APC-5M. Adaptive Process Control (APC) tracks the correct placement of components based on the solder printing position. Then, it transfers feedback to the stencil printer in case of misalignment. APC-5M detects 5M variations as well as line changes in real-time and ensures a smooth production process without downtime. Thanks to AI, the control system improves and specifies detections and feedback after each production process.

The sequential release of NPM G Series has started with additional solutions being released throughout the year.