ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

LG Chem Offers New PFAS-Free Flame-Retardant Material

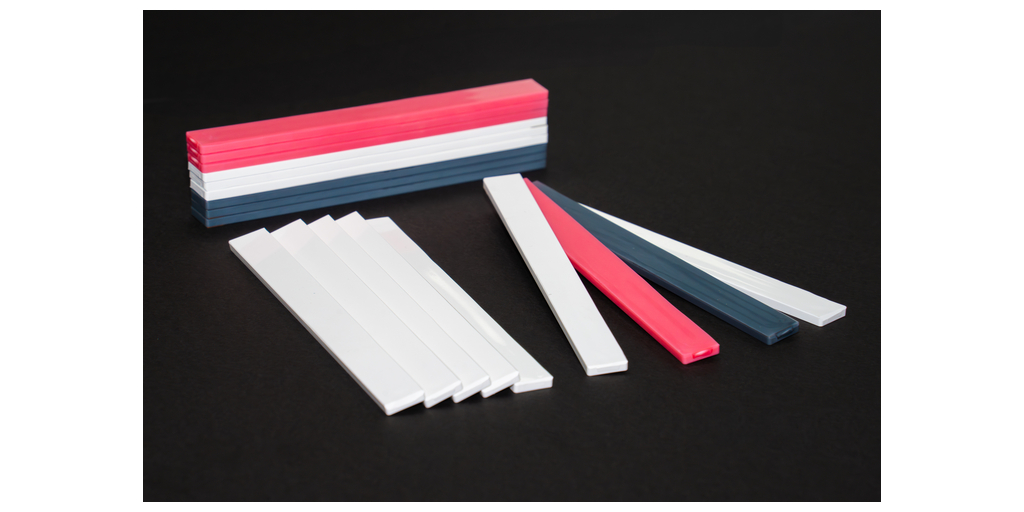

LG Chem has developed a PFAS-free flame-retardant PC/ABS material made of recycled plastics. Also, this material has received the V-0 rating in the UL94, a U.S. standard flame retardancy test.

LG Chem is the first to be certified for V-0 flame retardancy performance with PFAS-free PC/ABS material.

Mainly, the V-0 rating is the highest level of flame retardancy performance in the industry. Herein, the flame must self-extinguish within 10 seconds when the material is set on fire vertically.

With its own-developed special flame-retardant process, LG Chem has made its PC/ABS material more flame-resistant without PFAS. Also, it added PCR plastics to reduce carbon emissions. This PFAS-free material emits 46% less carbon compared to traditional PC/ABS materials as it contains more than 50% of recycled plastics.

High Demand for PFAS-Free Material

Commonly, PFAS is used in cooking utensils, clothing, and cosmetics as it is highly flame-resistant and does not dissolve in water and oil. However, as it does not decompose in nature and has a negative impact on the environment, the demand for PFAS-free materials is growing mainly in Europe and the U.S.

“The transition to eco-friendly materials, including PFAS-free flame-retardant plastics, will become a global trend. We will continue our research and development efforts to create eco-friendly and flame-retardant materials that prioritize customer well-being and the environment,” said Steven Kim, Senior Vice President of LG Chem’s Engineering Materials Business Unit.

Specifically, PFAS-free flame-retardant materials will be employed in various electrical devices such as laptops and tablets. These devices are often in close contact with the human body and generate heat. Also, industrial equipment such as inverters and electric vehicle chargers, will use these materials.

In addition to PC/ABS materials, LG Chem has successfully obtained UL certification for various PFAS-free flame-retardant materials it has developed, including PC and PBT.

-12 August 2024-