ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Kawasaki Robotics to Pitch New Cobots with Partners

Kawasaki Robotics will demonstrate new additions to its extensive robotics portfolio at IMTS in Chicago Sept. 9 to 14. This includes the new CL Series of intelligent collaborative robots (cobots) and new industrial robotic solutions.

Mainly, the CL Series cobots are available for order in multiple payloads. Moreover, the new industrial robotic solutions suit welding, machine tending and material removal. Collectively, they give manufacturers limitless flexibility and advanced capabilities when choosing automation to meet their diverse needs.

CL Series Creates New Era of Collaborative Automation

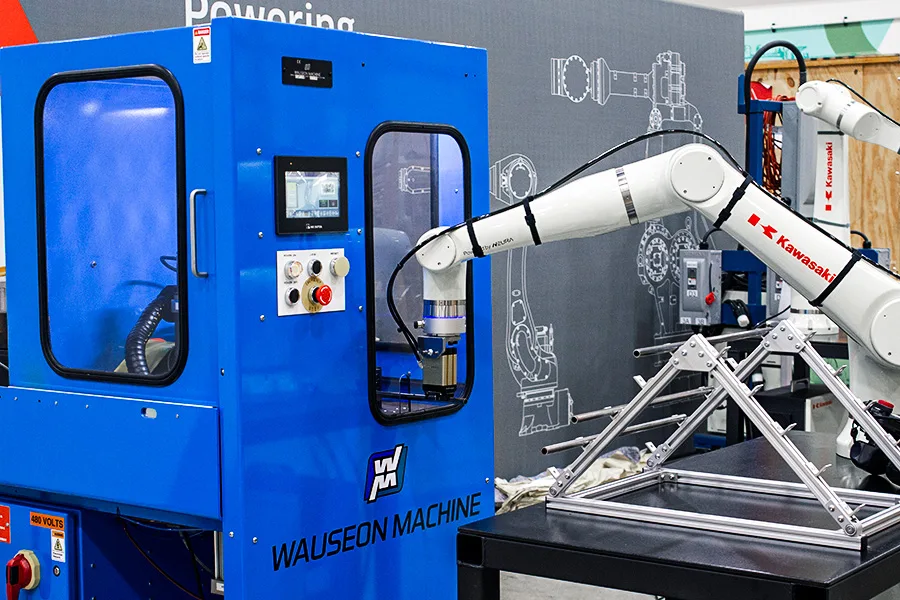

Developed in partnership with NEURA Robotics, the CL Series cobots challenge the current understanding of collaborative robots. Primarily, it offers full-on industrial scale performance and speed paired with maximum protection without compromising the safety and flexibility advantages of human/robot collaboration. Compact and robust, using the same durable casing as Kawasaki Robotics’ industrial robot arms, the CL Series cobots can operate without protective covers in crowded and harsh environments that may not be suitable for other cobots. Operating in Zero Gravity (Zero G), the CL Series cobots require only light guidance and precise adjustments by hand to create highly efficient solutions for applications such as machine tending and welding.

“With our CL Series cobots, we’re entering a new era of collaborative automation,” Amazawa said. “By providing advanced capabilities along with industrial-scale performance and speed as standard features, we boost productivity, improve product quality and worker safety, and reduce rework requirements. Our entirely new way and agile approach to collaborative robots enables manufacturers to more easily address labor shortages while yielding excellent return on investment.”

Specifically, the CL Series cobots support a variety of payloads and reach from 3kg/590mm to 10kg/1000mm, with higher payloads such as 15kg expected to hit the market within the next year. Built with high-quality components such as integrated 24-bit encoders, the CL Series operates with industry-leading speed of 200°/s and a repeatability of ±0.02mm. The intuitive user interface makes automating production lines easier than ever before. Free mounting orientations, extremely small footprint, and IP66 classification provide unparalleled flexibility. The proprietary safety architecture includes such features as limits and collision detection, enabling CL Series cobots to operate reliably alongside human workers.

Kawasaki Robotics will demonstrate the full family of CL Series cobots in a cooperative motion display at IMTS 2024. Meanwhile, a CL110 cobot will machine tend an upgraded Wauseon Machine 1004EL Electric End Forming Machine and an interactive display featuring a CL108 cobot will allow users to experience the CL Series Zero-G mode by hand guiding and recording programs using the lightest touch. Saved parameters improve setup consistency and reduce setup errors.

The other new robotic solutions being demonstrated at the booth of Kawasaki Robotics include:

Robotic Machine Tending Shelf System: This turnkey, no code, easy-to-set-up robotic machine tending solution using a modular shelf system for part feeding was developed in partnership with Hurco, a developer of CNC machining equipment. The demo features a Kawasaki RS013N robot, 16 workpieces—four fixtured to pallets and 12 held in 5th Axis LiteVises and a Hurco VM15Di CNC machine that is all operated using Hurco’s WinMax CNC Controls.

The design of the system aims to keep up with customer demand for high-mix, low-volume parts manufacturing without the need to learn how to program a robot. Ultimately, machinists receive a safe solution that can handle a range of part sizes and volumes and can expand capacity to meet highly specific application needs.

Welding Robots: Delivering top performance since the 1960s, these arc welding robots use state-of-the-art technology to increase quality and efficiency. New models featured at IMTS include the BA013N and BA013L with built-in intelligence, real-time path modification, and adaptive arc welding and RTPM capabilities to help manufacturers improve quality and meet production goals.

Robofin: Developed in partnership with AMT and NEFF Automation, this versatile robotic material removal solution solves various finishing needs. RoboFin can handle diverse materials and surface types, increase abrasive life up to 3X, and provide unrivaled precision and consistency to deliver the same high-quality output every time.

K-Positioners: These positioners enable robots to easily manipulate workpiece position to ensure the welding torch is positioned at the optimal angle and distance for consistent, high-quality welds. By automating workpiece movement, positioners speed up the welding process, reducing overall cycle times while at the same time reducing the need for reworking.

K-Tracks: Incorporating K-tracks simplifies reconfiguration of production lines and reduces the overall number of robots required as a single robot can now accommodate different products and processes. This flexibility is crucial in today’s fast-paced and ever-changing market conditions, enabling manufacturers to adapt quickly to new demands, requirements, and opportunities.

-09 September 2024-