ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Universal Robot Fortifies Presence in Japan

Headquartered in Denmark, Universal Robots A/S (UR) has been expanding sales of collaborative robots in Japan. UR established its branch office in Tokyo in June 2016. Since then, it has been delivering collaborative robots to various businesses in the country.

Globally, UR posted sales of US$78 million in Q3 of 2021 for a year-on-year growth rate of 46 percent. This surpassed 31 percent record growth in Q3 of 2019 before the pandemic.

Responds to Market Needs

AIDO INDUSTRY CO., LTD., which is based in Obu in Japan’s Aichi prefecture, is one of the companies employing UR’s robots. An original equipment manufacturer (OEM) of automotive components, AIDO has installed UR’s collaborative robots to perform various processes. At present, 40 units are operating in various processes, such as cleaning, leak test and blow processes of components.

FUJITA WORKS CO., LTD., a manufacturer of precision sheet metals based in Kirishima, Kagoshima Prefecture, has installed UR’s UR5 collaborative robot for welding and to feed workpieces to metal pressing machines. The company has installed three units of the UR5 and achieved tungsten inert gas (TIG) welding to support workers. In addition, OSAKA NURSERY, which is based in Hokkaido’s Nakagawa-gun, has installed collaborative robots in the production process of seedlings.

The Japan branch has opened a training course among its distributors under its innovative UR Academy. In fact, this has solicited positive feedbacks and has produced results as well.

The company has also expanded its Universal Robot+ (UR+) initiative, which combines its proprietary UR platform with the talent of the industry’s largest ecosystem. UR+ provides users access to a collection of peripherals and application kits designed for success. Furthermore, this has also contributed to the expansion of demand for UR’s collaborative robots. Developers develop peripheral equipment compliant with robot arm’s specifications and interface of Universal Robots. After UR certification, the developers sell the peripheral equipment as UR+ products.

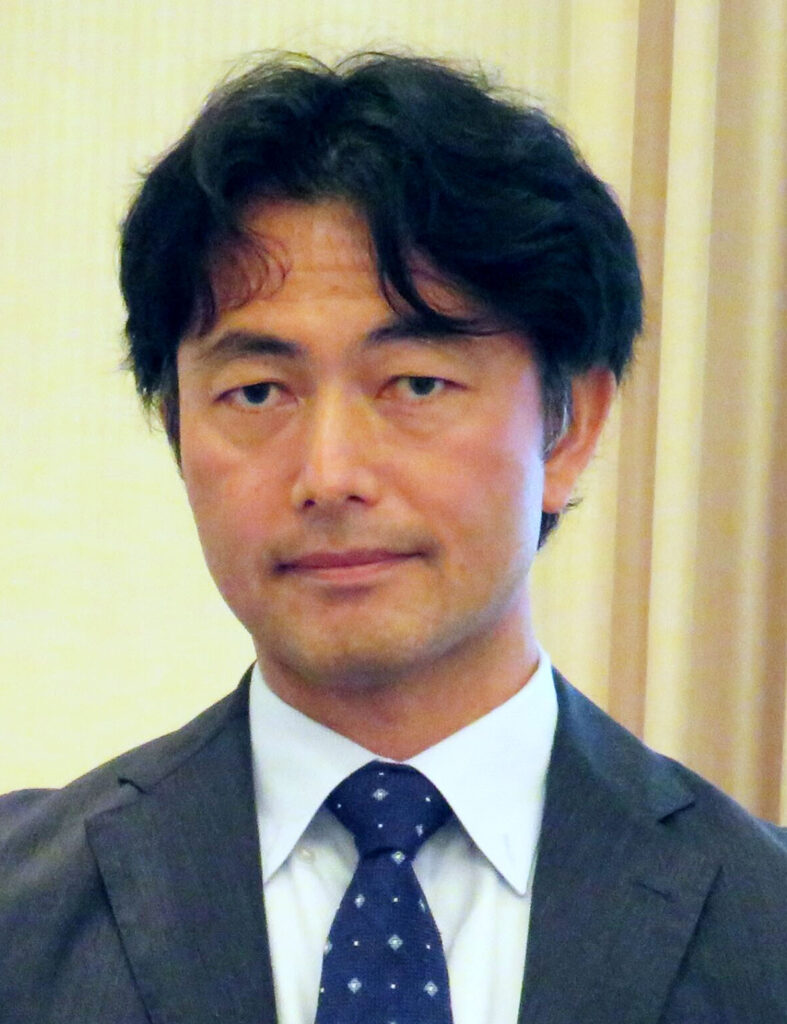

Tsuyoshi Yamane, Representative of Japan Branch, says, “In most cases, companies install collaborative robots to make up for labor shortages. Therefore, applications require to meet the needs of the production site.”

“Our company analyzes and understands Japanese customers’ needs and of the market in general. From there, we propose robots based on applications,” Yamane added.

Certified Platforms in Japan

At the core of UR Japan’s pitch is UR+ peripheral equipment platform that enables plug-&-play by combining related products and tools with UR robots. As such, Yamane said to achieve automation, their aim is to develop easy-to-use solutions in collaboration with manufacturers.

UR+ products made by Japanese manufacturers include ARH305A electric three-prong robot hand by ASPINA (Shinano Kenshi Co., Ltd.; and the SXR0030 manual robot hand changer of KOSMEK LTD. The list also included the ZXP-X1 Series vacuum gripper unit for collaborative robots, which SMC Corporation developed and manufactured and the RV Series three-dimensional (3D) machine vision systems by Canon, Inc.

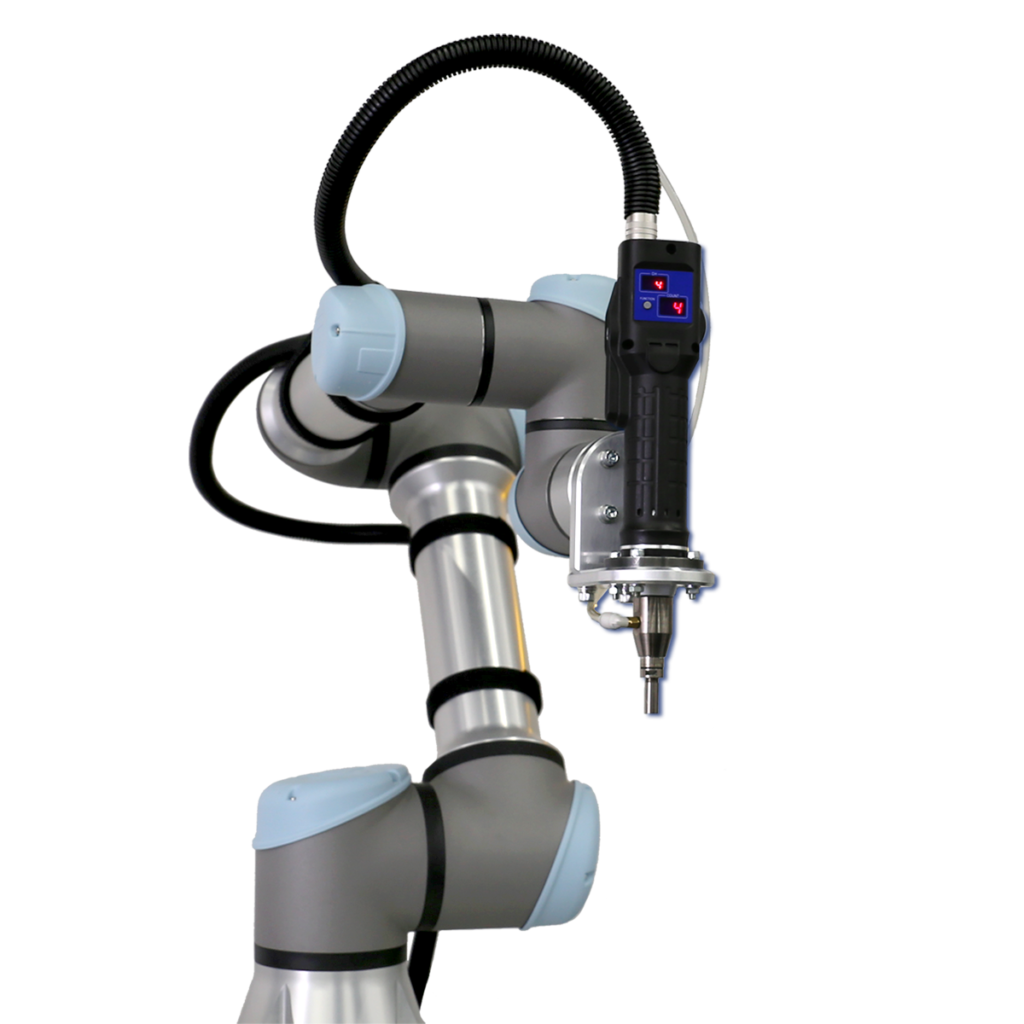

UR has newly certified the DLV45C Delvo electric screwdriver made by NITTO KOHKI CO., LTD. based in Ota-ku, Tokyo. The DLV45C enables 30 different torque settings on a single unit. Mounting the torque setting function, which has conventionally been performed manually, to an UR robot achieves semi-automation of torque setting.