ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Yokogawa Paves Way for High Tech Tool in Unique MES

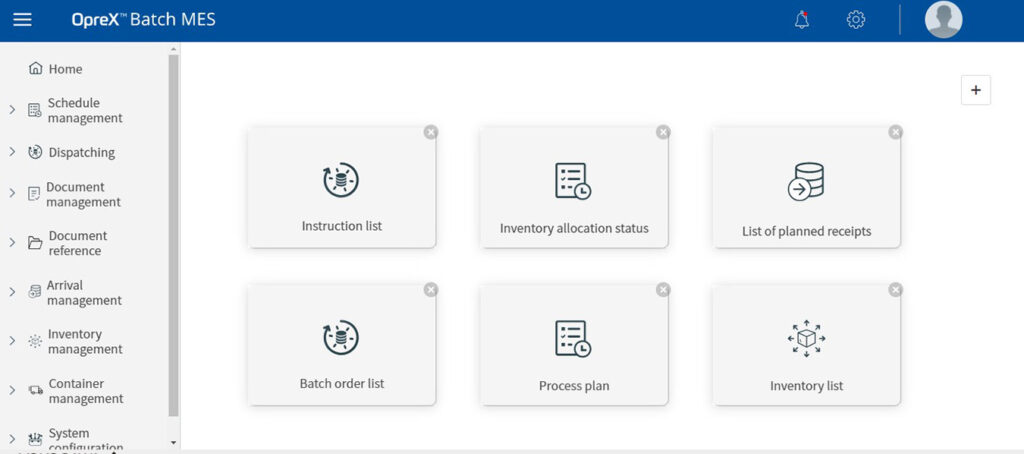

Yokogawa Electric Corporation has announced the global release of OpreX Batch MES. Accordingly, it will come as a product in the OpreX™ Asset Operations and Optimization family.

OpreX Batch MES is a manufacturing execution system (MES) package intended for use in batch plants. Thus, producing specialty and fine chemicals.

Development Background

Batch plants that produce specialty and fine chemicals consist of both automatic control and manual tasks in their production processes. This requires systems that can guarantee manufacturing procedures and rules. At the same time, reliable safekeeping of manufacturing records.

For that reason, preventing manufacturing defects and accidents, ensuring traceability, and facilitating the digitalization of processes and transfer of know-how. Specialty and fine chemicals come in high-mix, low-volume production and a short product lifecycle. Thus, customers need a certain level of flexibility to establish and revise manufacturing processes themselves.

Main Features

OpreX Batch MES is a software package for specialty and fine chemical batch plants. Specifically, it enables the management and confirmation of the status of manufacturing processes. Thus, providing support to operators and offers smooth linkage with enterprise resource planning (ERP) systems and integrated production control systems. OpreX Batch MES offers the following features:

- Flexible modification of manufacturing procedures

For added flexibility, modifications to manufacturing procedures can now all be done using a low code development approach. This includes modifications to recipes (a comprehensive set of instructions for the manufacturing process specifying items. Among them are the measurement of raw materials and the timing and temperature of specific processes), standard operating procedures (SOP: a set of step-by-step instructions on how to execute a specific process), and flow charts. - Encourages utilization of know-how and new learnings by accumulating the knowledge and linking it to the job

Conventionally, a handover on a work site involved passing information verbally or by means of a memo on a notepad or other such media, but now it is possible to digitally record and refer to new learnings and evidence consisting of free-format text, photos, video, and audio from a screen that is operated directly during production, helping to pass on know-how.

Major Target Markets

Batch plants that manufacture specialty and fine chemicals (semiconductor chemicals, semiconductor mounting materials, adhesives and sealants, construction chemicals, industrial cleaners, fragrances, high-performance resins, etc.)

04 November 2024