ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

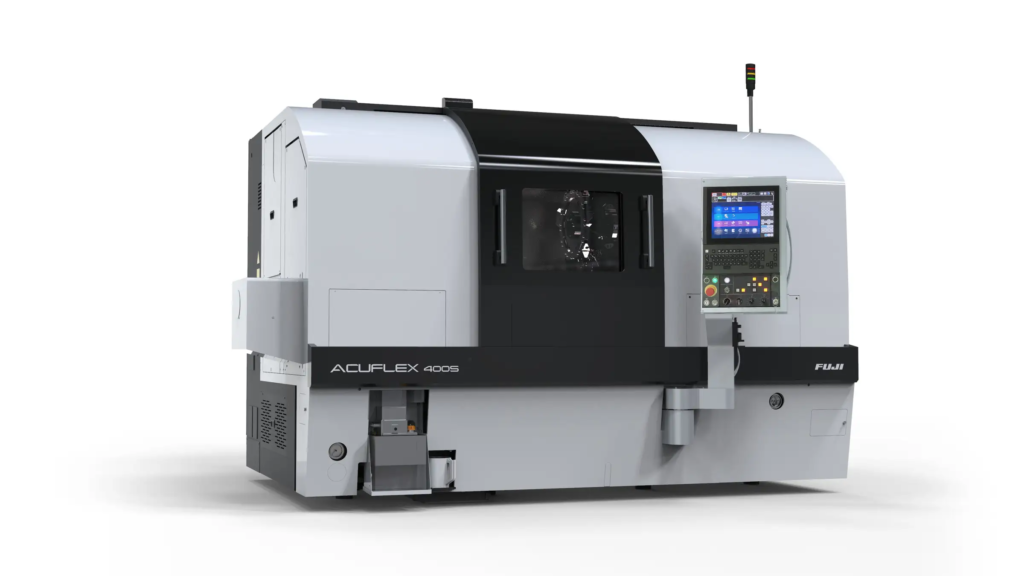

FUJI Accepts Orders for New Multi-Function Lathe

FUJI Corporation has started accepting orders for the newly developed product ACUFLEX 400S (Accuflex). Particularly, Acuflex is a single-turret type multi-lathe with a Y-axis.

Primarily, this product was developed by utilizing FUJI’s expertise in the development of lathes for automotive parts processing, which has been FUJI’s mainstay. Also, it combines a high degree of flexibility, high rigidity, and usability to reduce the burden on workers. Thus, these features make it a composite lathe that meets a wide range of machining needs. The lathe was developed following reference exhibitions in Japan and overseas, and field evaluations.

Development Background

In terms of the production form of automotive parts processing, an increasing number of customers are considering shifting to medium-to-medium-volume production while focusing on conventional mass-production models. Moreover, the demand for flexible production capabilities is growing. In addition, to meet the needs of a wide range of customers for various production forms, such as robot parts processing and semiconductor manufacturing equipment parts processing, FUJI has developed the ACUFLEX 400S, a single-turret type multi-lathe with a Y-axis based on the concept of flexibility and high rigidity, and is also easy to use.

Features of the ACUFLEX 400S

(1) Flexibility

Rotary tools of composite lathes made by other manufacturers that the customer already owns can be used as they are (*1). Spare parts can be shared.

Despite its compact appearance, it boasts a maximum machining diameter of φ460mm. Thus, it demonstrates a machining capacity that exceeds that of a composite lathe of the same size.

A long-neck turret (*2) that can be fitted with a boring bar with a long hang amount is used for backing processing on the right spindle. This enables deep hole drilling with the right spindle, which was difficult with conventional models. (*1: Excluding some manufacturers) (*2: Optional)

(2) High rigidity

The left spindle can be mounted up to 12 inches, and the right spindle can also be mounted up to 10 inches. In addition, both spindles were built-in motor specifications.

Even in the backing of the right spindle, we have ensured a class-leading level of sufficient rigidity that can withstand high-load machining.

Sliding slides are used for X and Y axis slides. The Z-axis slide uses a roller guide. It achieves both speed and high rigidity, and it is possible to shorten the cutting time.

(3) Usability

The front door has a large frontage of 885mm. Equipped with an assist function (*3) for door opening and closing operation. It is easy to open and close even for those with weak strength.

The front door has a structure that opens to the left or right, allowing you to approach and work where you need it in the shortest possible time.

The spindle height is 1,000mm, and the overall equipment height is 2,128mm, making it a compact size.

When exported, it can be loaded in a 40F high-cube container, and the shipping packaging material is minimized. (*3: Optional)

What’s Next

FUJI will exhibit at JIMTOF2024 to be held at Tokyo Big Sight on November 5~10, 2024, and exhibit the actual machine at its booth (E6021). In the actual machine exhibition, visitors can see a demonstration of the front and back processing of the turret gun head. In addition, the company plans to exhibit at major exhibitions in Japan and overseas one after another.

This article is an online translation of a press release in Japanese with slight editing made by Dempa.

-05 November 2024-