ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New ROHM 4-Gen IGBT Drives Inverter Efficiency

ROHM Co., Ltd. has developed a fourth-generation insulated-gate bipolar transistor (IGBT)(*1) that meets the AEC-Q101(*3) automotive reliability standard. Primarily, it achieves industry-leading low-loss characteristics and high short-circuit tolerance(*2) at a withstand voltage of 1200V. The product was designed for electric compressors and HV heaters for automotive applications and inverters for industrial equipment.

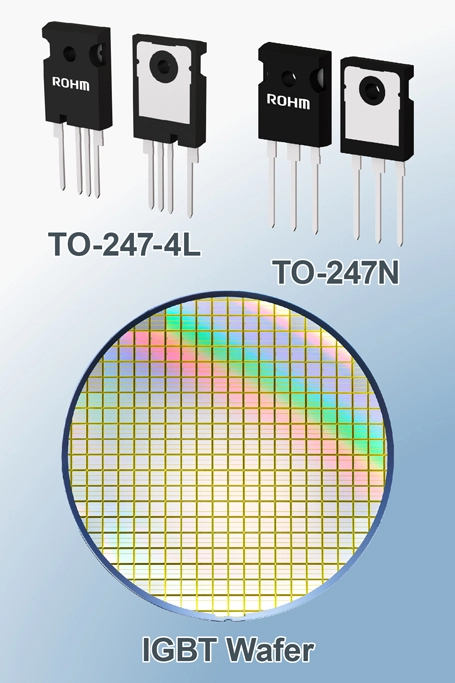

The products to be sold this time include four models “RGA80TRX2HR /RGA80TRX2EHR /RGA80TSX2HR/ RGA80TSX2EHR” in two types of discrete packages (TO-247-4L and TO-247N). Also, 11 models of bare chips “SG84xxWN” are available The lineup will be further expanded in the future.

Top-Class Short-Circuit Tolerance

Particularly, the fourth-generation 1200V IGBT achieves the industry’s top-class short-circuit tolerance of 10μsec. (at Tj = 25°C), low switching loss, and low conduction loss. At the same time, it ensures a high breakdown voltage of 1200V and reliability of automotive standards by reviewing the device structure, including the outer peripheral structure.

In addition, the new TO-247-4L package with four terminals can be adapted to an effective voltage of 1100V in an environment with a pollution degree of 2 (*5) by securing the creepage distance between the terminals (*5). Thus, it makes it possible to use higher voltage applications than conventional products. Since measures for creepage distance are taken on the device side, it can also contribute to reducing the design burden on manufacturers.

Moreover, the TO-247-4L package achieves high-speed switching by adding a Kelvin emitter pin (*6) to achieve even lower losses. In fact, when comparing the efficiency of the new TO-247-4L package product with a 3-phase inverter for general products and conventional products, it achieves a loss reduction of about 24% compared to general products and about 35% compared to conventional products. Accordingly, it contributes to high efficiency driving of applications.

For the time being, mass production of the new product has begun with a monthly production capacity of 1 million units (sample price 1,500 yen/piece: excluding tax). The front-end production is carried out by ROHM Co., Ltd. (Shiga Plant) and the back-end process is operated by ROHM Integrated Systems (Thailand) Co., Ltd. (Thailand). Online sales have also started. Customers can purchase chips from One Stop ™, Core Staff Online ™, etc.

In the future, ROHM will work to further expand its lineup of high-performance IGBT products. Specifically, it aims to contribute to high-efficiency drive and miniaturization in automotive and industrial equipment applications.

Background

In recent years, automobiles and industrial equipment have been increasing their voltages. Thus, there is a need to adapt them to power devices installed in automotive electric compressors, HV heaters, and industrial equipment inverters. Meanwhile, from the viewpoint of energy conservation, simplification of cooling mechanisms, and miniaturization of housings for the realization of a decarbonized society, there is a strong demand for higher efficiency in power devices. In addition, automotive electrical components are required to comply with automotive reliability standards. In addition, inverters and heater circuits require power devices to interrupt the current in the event of a short circuit. Also, they must have a high short-circuit tolerance.

Against this backdrop, ROHM has developed a new fourth-generation IGBT that is adaptable to high voltages. Also, it has industry-leading low-loss characteristics and high short-circuit tolerance by reviewing the device structure and adopting an appropriate package.

Glossary

*1) AEC-Q101 automotive reliability standard

AEC is an abbreviation for Automotive Electronics Council. It is a reliability standard for automotive electronic components that was formulated by a gathering of major automobile manufacturers and major electronic component manufacturers in the United States. Q101 is a standard applied to discrete semiconductor components (transistors, diodes, etc.).

*2) Short-circuit capability

When a load is short-circuited, it is the time that a power device can withstand without destroying it.

*3) IGBT (Insulated Gate Bipolar Transistor)

A power transistor that combines the high-speed switching characteristics of a MOSFET with the low conduction loss characteristics of a bipolar transistor.

*4) Creepage distance

The shortest distance along the surface of an insulator between two electrical conductors.

In semiconductor design, it is necessary to take insulation measures that ensure such creepage and clearance distances to prevent electric shocks, leakage currents, and short circuits (short circuits) in semiconductor products.

*5) Pollution level 2 environment

Pollution degree 2 is a state in which only dry, non-conductive contaminants are present. This corresponds to a general environment such as a home or office.

The degree of contamination is a grade of the environment that affects the spatial distance and creepage distance of the part, and is classified into 1~4 depending on the presence, amount, and condition of the contaminant.

*6) Kelvin emitter terminal

An emitter terminal dedicated to voltage measurement. By separating it from the emitter pin through which the current flows, the effect of voltage drop when the current flows can be minimized, and high-speed and stable switching can be performed.

This is an online translation of a Japanese press release with slight editing made by Dempa.

-07 November 2024-