ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

ROHM Sets Sights on Power Field with New Controller IC

ROHM Co., Ltd. has developed a general-purpose controller IC with an external pulse width modulator (PWM) control method (*1) field-effect transistor (FET) that is ideal for AC-DC power supplies for industrial equipment. A wide range of models are available, including the BD28C55FJ-LB for driving low-voltage MOSFETs, the BD28C54FJ-LB for driving medium- and high-voltage MOSFETs, the BD28C57LFJ-LB for driving IGBTs, and the BD28C57HFJ-LB for driving silicon carbide (SiC) MOSFETs. Mass production of the four models compatible with power transistors has started.

Product Features, Specifications

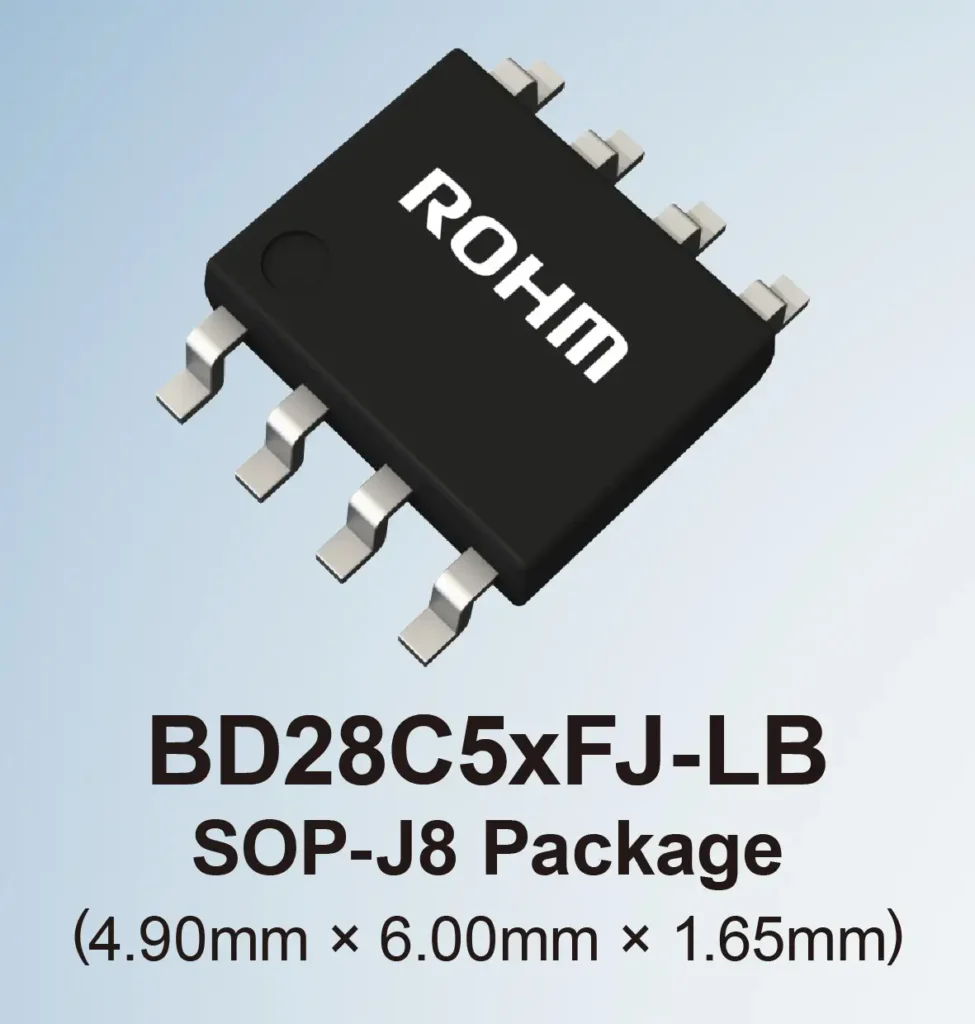

Primarily, the new product has an input voltage range of 6.9 to 28.0V, a circuit current of up to 2.0mA, a startup current of up to 75μA, a duty cycle (*2) of up to 50%, and a standard SOP-J8 (JEDEC standard: SOIC8 equivalent) package. The pin arrangement is the same as general-purpose products often used in power supplies for industrial equipment applications. As a result, it contributes to reducing man-hours when changing circuits or designing new designs.

Also, all models are compatible with self-resetting undervoltage lockout function (UVLO) (*3) with voltage hysteresis. Compared to the threshold voltage error of about ±10% for general products, the new product has a smaller threshold voltage error of ±5%. This feature enables highly accurate return start and contributes to better application reliability.

Furthermore, the company can supply the product in a stable manner over a long period of time. Thus, it can contribute to the continuous operation of long-life industrial equipment applications.

Mass production of the new product started in July 2024 at a monthly production rate of 100,000 units. The production base is ROHM Hamamatsu Co., Ltd. (Hamamatsu City) for the front-end process and ROHM Electronics Philippines, Inc. (Philippines) for the back-end process. The company also begins online sales, and available from Core Staff Online™, Chip One Stop™, etc.

In the future, the company will gradually add products compatible with high-voltage MOSFETs and GaN devices to the lineup. Also, it plans to commercialize products that support a maximum duty cycle of 100%.

Background

Although the global semiconductor shortage is subsiding, the supply of power supply components for industrial equipment and other devices is still not keeping up. Particularly, only a few manufacturers deal with AC-DC controller ICs, and the semiconductor shortage has been lingering. Moreover, the company has received many requests for product development.

Against this background, ROHM has commercialized a PWM control type AC-DC controller IC that meets the requirements for packaging and performance that are in high demand in industrial equipment applications.

Specifically, the new product suits industrial equipment, like AC-DC power supplies, motor drive inverters, and other applications that operate from electrical outlets.

Glossary

*1) PWM control method

PWM (Pulse Width Modulation) is one of the methods of controlling power using semiconductors. The output power is controlled by changing the ratio of the on-time and off-time within a certain period.

*2) Duty cycle

The time ratio of successive pulse waves in and off states to a given period. On-duty is the ratio of the On state and off-duty is the ratio of the Off state. It is common to use the on-state time ratio as the duty cycle.

Duty Cycle (%) = Pulse Width (t) ÷ Period (T)

*3) Self-restoring low-voltage lockout (UVLO) with hysteresis characteristics

UVLO is an abbreviation for Under Voltage Lock Out. When the input voltage drops above a threshold value, the IC internal circuit is safely stopped before it becomes abnormal. In the self-restoration type, when the threshold voltage is near, the IC repeatedly stops and returns and becomes unstable. Thus, a hysteresis characteristic protection circuit with a wide range of voltages at the time of stop and recovery is adopted.

This is an online translation of a Japanese press release with slight editing made by Dempa.

-21 August 2024-