ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Hitachi, UTokyo to Soar Research on Res Laser-PEEM

Hitachi High-Tech Corporation and The University of Tokyo (UTokyo) have been conducting joint research into practical applications of high-resolution Laser-PEEM*1. Specifically, UTokyo developed the high-resolution Laser-PEEM in the semiconductor manufacturing process.

The research will take spotlight in the forthcoming MNC 2024 (International Microprocesses and Nanotechnology Conference 2024), which will take place in Kyoto Prefecture from November 12 to 15, 2024.

Laser-PEEM can be faster image analysis compared to SEM*2 used in the semiconductor wafer manufacturing process. Furthermore, observation of the chemical information of materials and the non-destructive observation of 3D structures on the nano-level used high-resolution technology developed by UTokyo.

In this research, Hitachi High-Tech and UTokyo researchers conducted trials on the application of Laser-PEEM in the semiconductor field and have verified its effectiveness. For that reason, the research teams aims to conduct further research in collaboration. Specifically, by understanding the needs of semiconductor manufacturers to help resolve issues in the manufacturing and shipping processes.

Background

Semiconductor device performance has improved with the progress that’s been made in miniaturization and high integration, at present, nano-level circuit patterns are being formed using extreme ultraviolet (EUV) lithography. As devices become increasingly miniaturized and highly integrated, changes in 3D processing precision of circuit patterns and localized material properties in the manufacturing process have come to have a greater impact on device performance than ever before. For that reason, multi-point and varied inspections and measurements are becoming essential. Thus, the need for improved inspection throughput is expected to continue to increase going forward.

Hitachi High-Tech has been conducting joint research with UTokyo since 2020, which developed the high-resolution Laser-PEEM technology. Moreover, it aims at resolving further issues facing customers by leveraging Hitachi High-Tech. Specifically, in supporting semiconductor manufacturing through high reproducibility and throughput.

Details of This Research’s Trials Using the Features of High-resolution Laser-PEEM

- Quick nano-scale observation

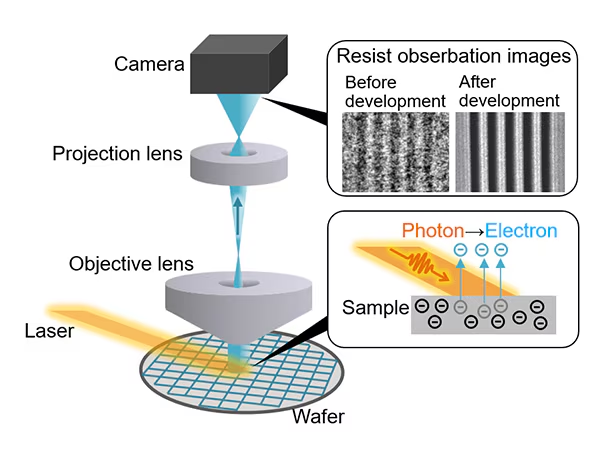

Laser-PEEM irradiates the entire observation target with a laser instead of an electron beam, and obtains the observed image by capturing the electrons emitted from the observation target with a camera. This research has verified that, using this method, it is possible to obtain a wider area of high-resolution data at once. Thereby, contributing to substantially shortening the inspection process compared to a SEM, which scans using an electron beam.

2. Enables the observation of various chemical information of materials

The semiconductor manufacturing process consists of three main processes: resist coating, exposure, and development. In order to inspect the shape of circuit patterns, we currently inspect the uneven patterns formed on the wafer surface after development.

Yield could be improved if it were possible to inspect what are called latent image patterns, which are formed immediately after exposure and are chemically etched with no irregularities on the actual surface. In this research, we applied Laser-PEEM to latent image pattern observation and demonstrated that it was possible to observe them at high resolution and with high throughput. This functionality is a technique that was not possible with SEMs, and we anticipate this could lead to the creation of new inspection markets going forward.

3. Enables non-destructive observation of nanostructures

Laser-PEEM is capable of sensing at depths of approximately 10 to 100 nanometers, and we have demonstrated that it is able to “look through” and see whether defects are present in wafers and what caused them in a non-destructive manner. This makes it possible for the previous work of processing wafers to analyze the cause of faults to now be carried out non-destructively. We also expect to see more advances in moving to three-dimensions going forward, thereby contributing to reducing the workload involved in processing, as well as more accurate analysis.

Future Outlook

Hitachi High-Tech has been providing inspection and measurement equipment using electron beam technology and optical technology. Thus, the company continues to respond to customers’ various processing, measurement and inspection needs in the development of semiconductor devices. Moreover, in the future, the high-resolution technology developed by UTokyo and Hitachi High-Tech’s automation and stabilization technology will open up new possibilities. Specifically, for applying high-resolution Laser-PEEM in inspections and measurements in the cutting-edge semiconductor manufacturing processes.

In addition, the research anticipates that Laser-PEEM, which enables the acquisition of even more information from the observation target, will contribute to a wide range of industries and fundamental scientific research. As such, the research will continue our research in the application of technology toward resolving a wide range of social issues.

“We will continue to provide innovative and digitally enhanced solutions to our products for the upcoming technology challenges, and create new value together with our customers, as well as contributing to cutting-edge manufacturing,” said Hitachi High-Tech.

07 November 2024