ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Fuji Electric's New Investments to Soar Capacity Grit

Fuji Electric Co., Ltd. will make capital investment at its Tsukuba Factory in Inashiki-gun in Japan’s Ibaraki Prefecture. Therefore, expanding its production capacity for switchboards and power supplies.

With the rapid spread of generative AI, the construction of data centers and semiconductor factories is expanding, and demand for the necessary equipment to maintain a stable supply of electricity is increasing quickly. Also, Japan is seeing the aging of the social and industrial infrastructures introduced during its period of high economic growth, resulting in increased demand for the replacement of switchgear and power supplies.

Fuji Electric manufactures switchgear and power supplies for these types of equipment at its Kobe Factory in Kobe City and Tsukuba Factory. Its Kobe Factory is already in the process of expanding its

production building and installing production equipment, scheduled for completion in October 2026, with plans to increase production capacity by 1.5 times thereafter.

The company has recently made a decision on capital investment at the Tsukuba Factory; in addition to constructing a new production building, it will also upgrade production equipment (cranes and test equipment) to increase its switchboards and power supply production capacity to approximately 1.7 times the current level. Construction is scheduled to begin in September 2026 toward completion in November 2027.

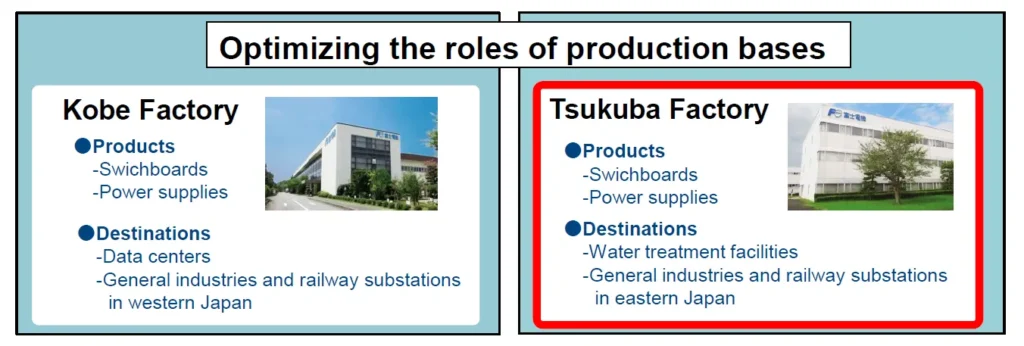

Meanwhile, the company will also work to optimize the roles of production bases at the Kobe and Tsukuba Factories. The Kobe Factory manufactures switchboards and power supplies for data centers, general industries (e.g. factories, commercial facilities), and railway substations, and the Tsukuba Factory for general industries, railway substations, and water treatment facilities. The production of general industries and railway substation products will be allocated to one of the two factories according to the destination.

While increasing production capacity to address strong demand for electricity, the company will also expand standardized design and automated production to further improve productivity and reduce production lead-times.

04 February 2026