ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Ultium Cells to Build US$2.6 Billion EV Battery Facility Around Siemens' Smart Factory Platform

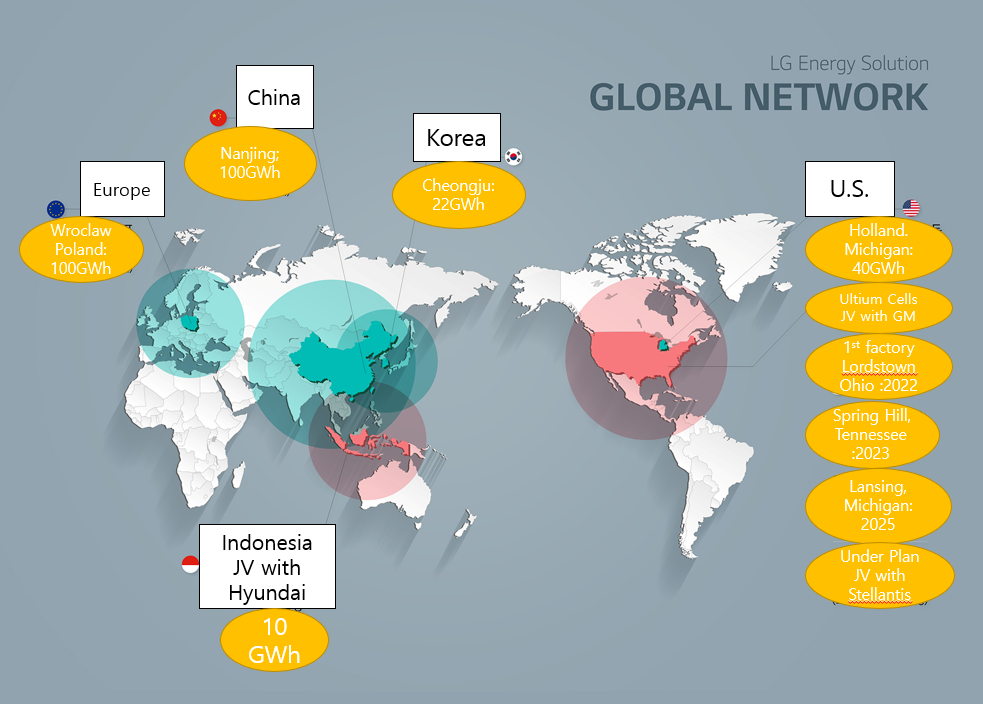

Ultium Cells, a JV between LG Energy Solution and GM, will invest US$2.6 billion to establish its 3rd EV battery production facility in Lansing, Michigan in what the JV said will be built around a smart factory platform.

Scheduled to break ground in 2022, the EV battery factory will come online in the second half of 2024.

Commercial production will begin in early 2025, operating at an annual capacity of 50GWh. The capacity is equal to powering 700,000 pure EVs, of which each can drive more than 500km in a single battery charge. The factory will sprawl on a land lot of 2.8 million square feet, supplying Orion Assembly in Michigan and other GM EV assembly plants.

LG Energy Solution has already signed an alliance with Siemens of Germany to cooperate to digitalize LG’s EV battery manufacturing facilities.

The two companies are now working together to implement smart battery manufacturing processes at Ultium Cells’ Tennessee EV battery facility, embarking on a digital twin roadmap to ensure stable operations across EV battery facilities.

“This significant investment demonstrates our commitment to strengthen our Michigan and U.S. manufacturing presence and grow good-paying jobs,” said Mary Barra, GM Chair and CEO. “We will have the products, the battery cell capacity and the vehicle assembly capacity to be the EV leader by mid-decade.”

“With a shared vision, GM and LG Energy Solution pioneered the EV sector by seizing new opportunities in the market well before anyone else did,” said Young-Soo Kwon, CEO of LG Energy Solution. “Our third battery manufacturing plant, fittingly located in America’s automotive heartland, will serve as a gateway to charge thousands and later millions of EVs in the future.”

Once the Lansing EV battery fab completed, the JV will have an annual capacity of 120GWh combined.

The JV is now constructing two EV battery manufacturing facilities in Ohio and Tennessee, which will have an annual capacity of 35GWh each. The Ohio factory will come online in 2022, while the Tennessee facility will begin production in 2023.

The state-of-the-art Ultium Cells Lansing plant will use the most advanced and efficient battery cell manufacturing processes to stay extremely flexible and adaptable to ongoing advances in technology and materials.

GM’s proprietary Ultium battery technology is at the heart of the company’s strategy to compete for nearly every EV customer in the marketplace, whether they are looking for affordable transportation, luxury vehicles, work trucks, commercial trucks or high-performance machines.

Ultium batteries are unique in the industry because the large-format, pouch-style cells can be stacked vertically or horizontally inside the battery pack.

This allows engineers to optimize battery energy storage and layout for each vehicle design. Energy options range from 50 to 200 kilowatt hours, which could enable a GM-estimated range of up to 450 miles or more on a full charge with 0-60 mph acceleration in 3 seconds1.

GM’s future Ultium-powered EVs are designed for Level 2 and DC fast charging. Most will have 400-volt battery packs and up to 200 kW fast-charging capability while GM’s truck platform will have 800-volt battery packs and 350-kW fast-charging capability.