ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Digital Twin Technology Boosts FUJI Smart Factory

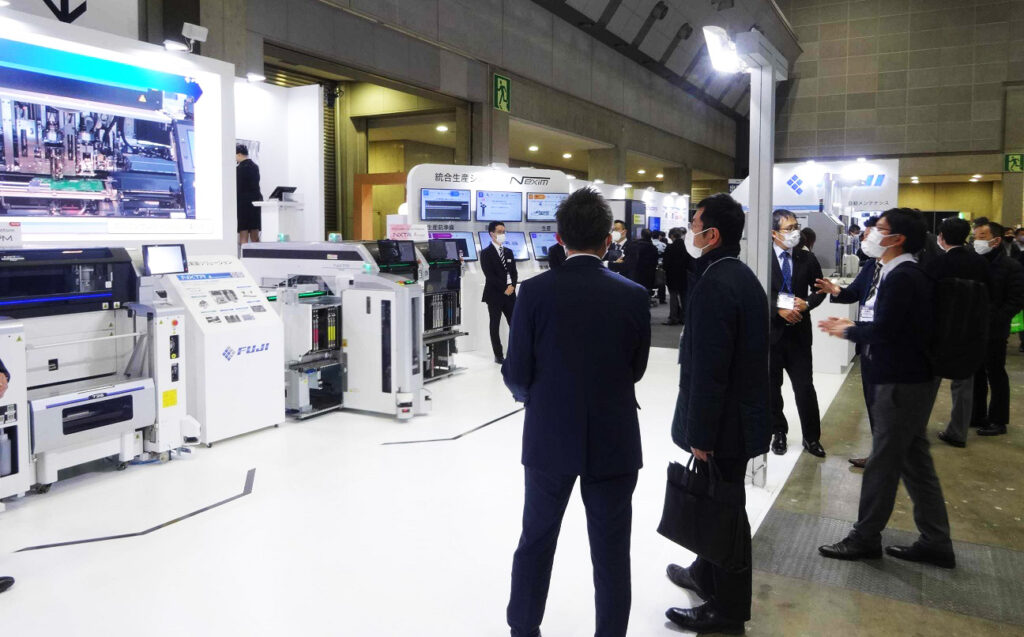

FUJI Corporation continues to advance the FUJI Smart Factory (FSF) by introducing digital twin technology to improve ease of use. The company also expands the lineup of machines for the post-process of mounting to upgrade. It pitched FSF that meets diverse needs at NEPCON Japan 2022 held in Tokyo in January.

FUJI Smart Factory

FUJI has been promoting FSF, which is based on the Nexim integrated production system, on the global markets. FSF leverages internet of things (IoT) and machine-to-machine (M2M) technologies, such as automated production changeover. It realizes flexible and efficient production. Last year, the company also released the NXTR next-generation mounter platform on full scale to support FSF.

NXTR comes in the NXTR A model and the NXTF S model. NXTR A is equipped with an automated feeder exchange system while NXTR S enables feeders to be exchanged manually.

Masaaki Sugiura, Managing Executive Officer, Board Member, FUJI Corporation, says, “FSF has been evolving and expanding into a system that facilitates installation in manufacturing sites. We propose digital twin as a simulation technology, while expanding systems that feature general versatility, to meet a wide range of customer needs.”

Market View

Sugiura shared his views on the market and the company’s business. “The Chinese market accounts for about 50 percent of our sales. In China, mounters have been selling well mainly to manufacturers of smartphones, peripheral devices, fifth-generation (5G) equipment and automotive electronics. These include Taiwanese electronic manufacturing services (EMS) companies.

Several years ago, production shift from China to countries in Southeast Asia started to advance. The trade tension between the United States and China affected this trend. However, some manufacturers are returning to China as lockdowns prompted by the COVID-19 pandemic continued in Southeast Asia.

Concerns about shortages of components and materials will still remain this year. However, factors that will drastically drop the demand for mounters are not visible. “I expect that the same level of demand as in 2019 will continue,” confirms Sugiura.

Rich Machine Lineup

FUJI provides a wide range of machines that constitutes a mounting line. These include solder printers, electronic components mounters, general-purpose assembling machines, and automated components warehouses.

It also provides systems that complement the mounting line, such as automated optical inspection systems, through collaboration with partner companies. FUJI has about 40 partner companies around the world.

The company has been promoting the automation of mounting line through linkage with other companies’ systems. It uses the SEMI SMT-ELS global M2M communications standard for surface mount technology (SMT) lines for integration.

Put Robot Technology at Core

“We have been taking the challenge to innovate by setting the robot technology as base of our growth strategy to usher in the new era. Based on technologies we have nurtured in the production of mounters, we will further promote labor saving and automation of production,” Sugiura.

He also put emphasis on building on partnership to improve value of solution. “We would like to create new values and strengthen our capability to offer a holistic proposal. (We will do this) by taking advantage of our synergy with Fasford Technology Co., Ltd. (FFT), a semiconductor manufacturing equipment manufacturer that is now our subsidiary.”

NEPCON Japan 2022

At NEPCON Japan 2022, FUJI has displayed the SW-BA Panel Assembly Robot Cell equipped with the SmartWing SCARA robot. The robot cell automates assembly work, such as the mounting of odd-formed components. It provides various functions needed for the automation of manual work in one package. This allows installation by customers at low cost.

The company has added sFAB-SH as a new automated solution in the manual insertion process. It has specialized functions needed for the assembly of general panels, while inheriting sFAB-D’s versatility, scalability, and productivity features. sFAB-SH flexibly supports high-speed insertion to the insertion of large components measuring 55mm tall and 200g in weight by exchanging two heads – sH08-SH and sH02-SH.