ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

NAGANO KEIKI Widens Array of Pressure Measurement Equipment

Established in 1896, Japan-based NAGANO KEIKI CO., LTD. has expanded its product range from pressure measurement equipment to encompass measurement control technology. The company has earned credible reputation from users for the quality and performance of its pressure gauges and pressure sensors.

The company has actively developed its strategies for the overseas markets. At present, it has a global sales network that spans Asia and countries in Europe, and the United States. In recent years, the company has stepped up efforts toward achieving a carbon-free society. It has been contributing hydrogen and ammonium to the next-generation energy industry by leveraging pressure measurement control technology.

Products for Semiconductor Industry

For the semiconductor industry, NAGANO KEIKI handles pressure transmitters and pressure gauges. These products monitor gases, chemical solutions, exhausts, and air conditioning used in semiconductor manufacturing processes.

ZT11, ZT17 Pressure Transmitter

The ZT11 pressure transmitter is installed in various locations of the gas supply system. These include gas cylinder cabinet and bulb manifold box, which branches a gas and sends it to use points. This equipment for measuring gases employs a semiconductor strain sensor gauge (SS sensor), which measures the increase and decrease of resistance value in accordance with external force. The SS sensor is suitable for the measurement of high pressures.

The ZT11 features an increased safety type construction of IEC Ex, ATEX and TS. It is adopted by leading power semiconductor manufacturers in Japan and countries in Europe, as well as by leading Taiwanese foundries. While ordinary sensors have operating temperature range of up to 70℃, ZT17 is resistant to high temperatures up to 120℃.

Further, NAGANO KEIKI has been developing sensors that withstand up to 200℃, responding to demands to efficiently introduce high purity gases by vaporizing them near the equipment instead of sending them using pipes.

JB50 Pressure Gauge

While pressure transmitters are used for centralized monitoring, the JB50 pressure gauge with a lead switch contact is used to visually observe measurement value on the production site. In case of emergency, the setting of alarm contact can be arbitrarily changed by manually moving the setting pointer. The gauges can generate an alarm when excessive pressure is observed in the system.

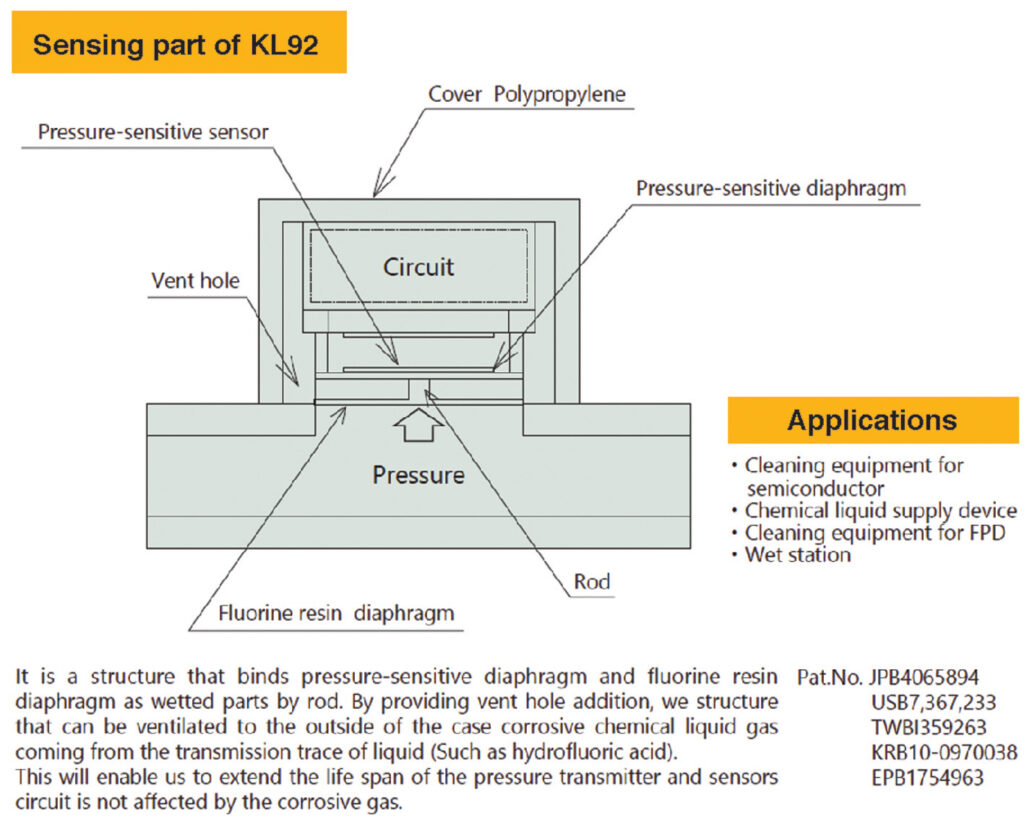

KL92, KL91 Pressure Transmitter

The KL92 pressure transmitter for the chemical solution process features an O-ring less structure, enabling rare occurrence of contamination and little metal elusion. Hence, it can be applied to pressure monitoring of the entire system that supplies chemical solutions in semiconductor manufacturing. The company owns a patent for the pressure receiving structure using a fluorine resin diaphragm seal. It has a vent hole to ventilate minute amounts of corrosive gases that permeate from chemical solutions, such as hydrofluoric acid, to the exterior of the case. It prevents circuits and sensor elements from being affected by corrosive gases and ensures long life of the product.

The company also offers KL91 for ultrapure water, which suppresses liquid accumulation and supports negative pressure and low pressure measurements. These pressure transmitters are used to optimize quantities of chemical solutions to be used in processes, such as wafer cleaning equipment and coater developers used in the lithography process. The company has a track record of continuously delivering these transmitters to semiconductor equipment manufacturers in Japan.

SL85 Anti-Corrosion Pressure Gauge

The SL85 anti-corrosion pressure gauge employs fluorine resin for bellows, which are pressure receiving elements, and the connecting part, to increase anti-corrosion property. It also employs polypropylene (PP) for the enclosure and polyethylene terephthalate (PET) for the window to increase resistance to atmospheric corrosion.

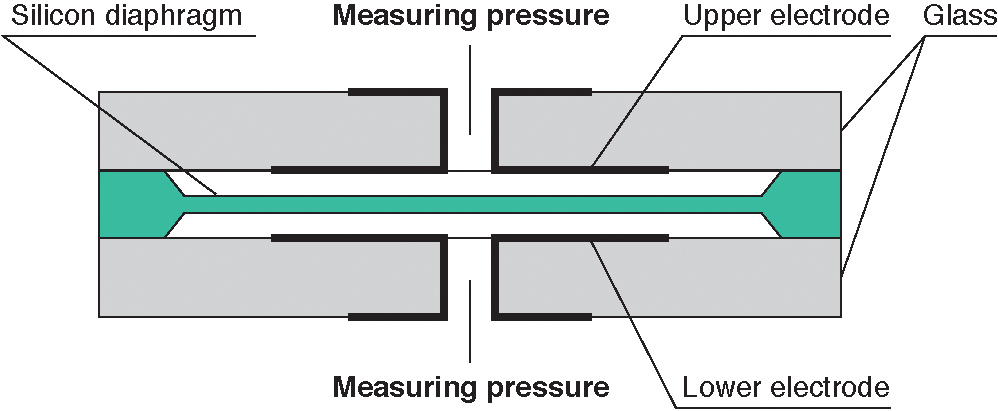

GC30, GC32 Digital Fine Differential Pressure Gauge

Meanwhile, the company recommends the GC30 and GC32 digital fine differential pressure gauges for exhaust adjustment at the process switchover in manufacturing equipment and filter clogging monitoring of fan filter units. They are silicon high precision, and have high sensitivity. With high resolution of 0.01Pa, they contribute to high-precision control of semiconductor air conditioning systems.

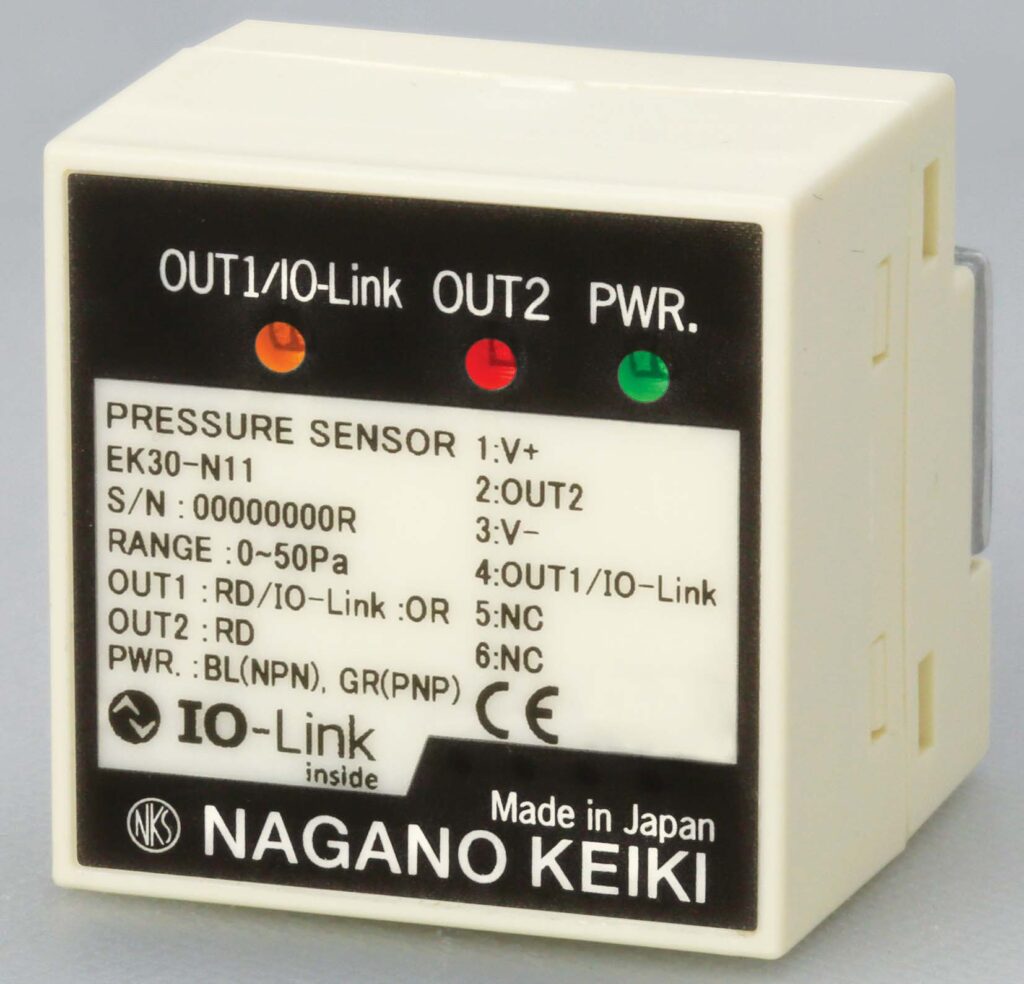

As a new product in 2022, the company has released EK30, which supports IO-Link, for semiconductor air conditioning systems, with which digitization advances.