ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

SDK Brings 6-inch SiC Single Crystal Wafers to Mass Production

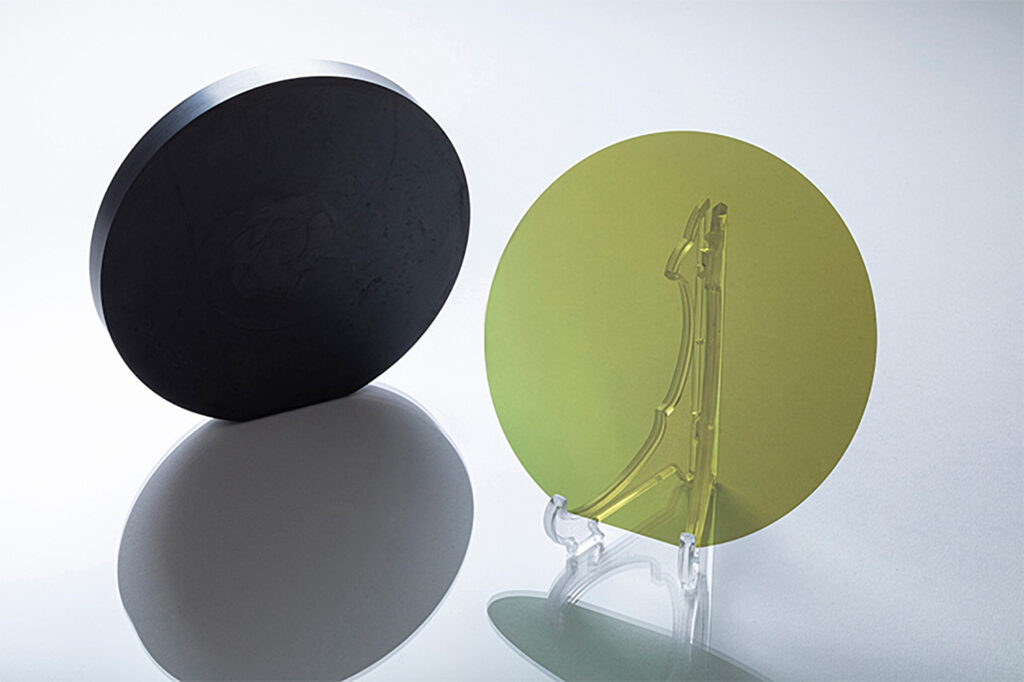

Showa Denko K.K. (SDK) has launched mass production of silicon carbide (SiC) single crystal wafers with a diameter of 6 inches. These materials are used for SiC epitaxial wafers1, processed and installed into SiC-based power semiconductors.

Properties Suitable for Power Module

SiC power semiconductor has excellent heat-resisting property. Also, it features high withstanding voltage much better than conventional silicon-based power semiconductor, which is today’s mainstream power semiconductors. SiC power semiconductor contributes to improvement in power module’s energy efficiency and downsizing. Therefore, the demand for SiC power semiconductors is increasing rapidly in various fields, like electrified vehicles (xEVs), railcars, and industrial equipment.

As an independent supplier of SiC epitaxial wafers, SDK has the global-top share in the market. Moreover, it has been providing power device manufacturers with best-in-class SiC epitaxial wafers. Therefore, SDK’s SiC epitaxial wafers are highly acclaimed by power device manufacturers in and outside Japan.

In-House Development

SDK has been considering in-house production of SiC wafers, which are used as main material for SiC epitaxial wafers. With this policy, the company aims to improve the quality of its SiC epitaxial wafers and establish a stable supply system.

From 2010 to 2015, SDK took part in “Novel Semiconductor Power Electronics Project Realizing Low Carbon Emission Society2”. It was hosted and entrusted by the Ministry of Economy, Trade and Industry and New Energy and Industrial Technology Development Organization (NEDO), as a member of the “Research and Development Partnership for Future Power Electronics Technology3.” Furthermore, SDK took over in 2018 the SiC-wafer related assets of Nippon Steel & Sumitomo Metal Group (Nippon Steel Group)4. Since then, it has been developing technologies for mass production of SiC wafers.

This time, SDK decided to launch in-house mass production of 6-inch SiC wafers. This decision was based on various customers’ adoption of SDK’s SiC epitaxial wafers made from in-house produced 6-inch SiC wafers.

However, SDK will continue purchasing SiC wafers from its partners to respond to rapidly growing demand for SiC epitaxial wafers for power semiconductors. Thus, SDK will diversify sources of SiC wafers, thereby establishing stable supply chain for SiC epitaxial wafers.

The Showa Denko Group aims to be a “Co-Creative Chemical Company”. It targets to contribute to the sustainable development of global society. Under this vision, SDK positions the production of SiC epitaxial wafers, promoting efficient use of energy, as a next-generation business. Also, the company will allocate much of its business resources to this area.

The Group will continue contributing to the spread of SiC power semiconductors. It will do so by maintaining “Best in Class” as its motto. The company will also continue provision of high-performance and highly reliable products.

Footnotes:

1SiC epitaxial wafer is a material for semiconductor, made from SiC wafer by depositing thin layer of epitaxial SiC on the surface of the wafer.

2Novel Semiconductor Power Electronics Project Realizing Low Carbon Emission Society is a project aiming to establish technology for realization of stable supply of SiC wafers with large diameters. In 2010, this project was started and entrusted by the Ministry of Economy, Trade and Industry. In 2011, the control of this project was transferred to New Energy and Industrial Technology Development Organization (NEDO).

3Research and Development Partnership for Future Power Electronics Technology is an association established as a joint organization of academy, industry, and government aiming to improve technical level concerning next-generation power electronics.

4For details of this, please refer to SDK’s news release, “Showa Denko Acquires Assets Concerning SiC for Power Devices from Nippon Steel & Sumitomo Metal Group,” which was announced on August 7, 2017.